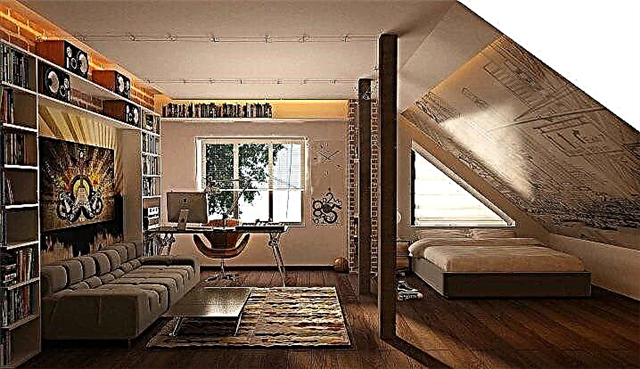

Quite often, the owner of a private house seeks to "squeeze" the maximum living space out of the building. The solution is simple - to turn a non-residential attic into a living room, which is usually called an attic. The question arises: what materials to choose and how best to finish the attic, so that under the roof it lives no worse than in the rest of the house? Consider solutions.

Lining

So in everyday life they call narrow tightly fitting boards with grooves and crests. It was from this material that the walls of cars were previously made. Clapboard decoration is considered the most suitable for living quarters:

- the absence of unhealthy secretions that are characteristic of many modern synthetic materials,

- beautiful natural pattern on the surface,

- low thermal conductivity: the wood is warm to the touch, which is especially important for flooring.

The lining of the attic with a wooden lining gives the room coziness and warmth.

The lining of the attic with a wooden lining gives the room coziness and warmth.

Wooden cladding creates a special cozy atmosphere in the room, and no other material can be compared with it. But at the same time lining:

- has a relatively high cost,

- capricious to temperature and humidity conditions: as soon as the conditions deviate from the norm, the wood can dry out or warp,

- in the form of a floor covering needs periodic maintenance (polishing) as it does not differ in special durability.

There are several varieties of lining, which vary greatly in cost. Their distinguishing features:

- Premium lining - the most expensive. It has no visible defects, knots or chips, very smooth. Usually produced by splicing, sold complete with fasteners and in special packaging, which avoids damage during transportation,

- lining of the first grade (class A) has minor defects: a small percentage of knots, through cracks, not more than 20% of the core. It is used in the front decoration of houses, covered with varnish or wax, which allows you to preserve the natural look of the material,

- lining of the second grade (class B) is characterized by a significant number of visible defects. On such boards there is resin, blue, core, non-through cracks. Boards on which marriage is very noticeable are overwritten and painted with dark paint or dark varnish on wood,

- lining of the third grade (class C) is very low in quality, but at the same time the cheapest. Non-residential premises are decorated with such boards. A lot of defects: falling knots, chips, through cracks, bark. Class C wall paneling must be significantly customized for wall cladding.

Wood, regardless of breed and grade, must be protected from moisture and mechanical wear. For this purpose, three different compositions are used:

- varnish. The most strong, reliable and durable protection. The disadvantage is that there is no possibility of local repair, that is, if the floor is damaged somewhere, then after replacing the lamella, the lacquer coating will have to be applied again to the entire floor or wall,

- butter. Oil impregnation is cheaper and does not require restoration of the coating on the entire surface after local repair. But in terms of durability, such protection is much inferior to lacquer, in addition, it almost does not protect wood from mechanical wear,

- wax with additives. Such a coating began to be used relatively recently. It combines the advantages of both of the previous types: it can be partially restored and at the same time it is almost as persistent as varnish.

Some manufacturers today produce a board with already applied varnish. This is convenient, but it must be borne in mind that such protection is not complete, since water can enter the gap between the lamellas.

Block house

Another type of wood cladding. Everyone knows what a croaker is a rounded sidewall of a log, which is cut to turn the trunk into a beam or when dissolving it on an unedged board. This material is a woodworking waste and is sold very cheaply. The block house is a calibrated slab, which is specially made as a finishing material. All the blocks of the block house have the same width and even edge, and grooves are cut on the back side to relieve internal stresses (prevent cracking). The idea is that the wall lined with this material looks as if it is made of logs.

A block house imitating a log wall is recommended for use in cladding village houses

A block house imitating a log wall is recommended for use in cladding village houses

It should be noted that the block house has a different width and, accordingly, a bulge of different thicknesses. Wide boards are used for cladding buildings on the outside, and for internal work they use narrow boards, which, due to the small bulge, take up a minimum of space.

Imitation of a bar

In fact, this is the same lining, only wider and with corners cut off on the front side. Like a block house, this finish is an imitation, not just of a round log, but of a rectangular beam.

The use of imitation timber with a width greater than that of the lining allows to reduce the time for wall cladding

The use of imitation timber with a width greater than that of the lining allows to reduce the time for wall cladding

Since both the block house and timber imitation are used only for wall or ceiling cladding, they are usually made of soft coniferous species. Due to the high resin content, such wood has a high resistance to moisture, insects and microorganisms.

Having decided to opt for lining, block house or imitation of timber, consider the following: since the attic is by definition a cramped room, it is advisable to use light wood species - spruce, fir, ash, maple. Light finish, as you know, creates the illusion of spaciousness.

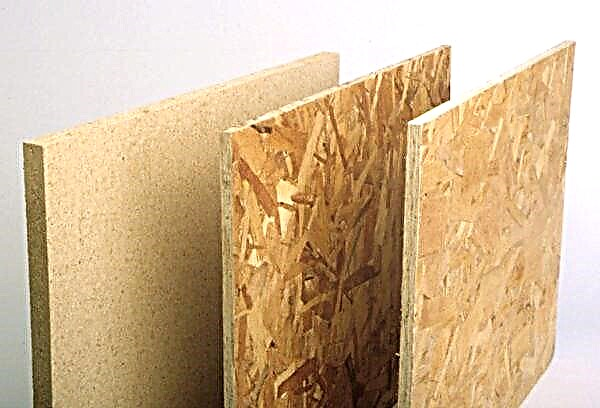

Chipboards - Particleboard, OSB and MDF

These relatively cheap materials are made from wood waste - shavings or wood chips. The wood base is mixed with a binder, after which it enters the press. Unlike solid wood, such materials endure loads worse, especially bending.

Chipboard - a domestic version in which the chips are located randomly.

Finishing the attic with chipboard makes it possible to save

Finishing the attic with chipboard makes it possible to save

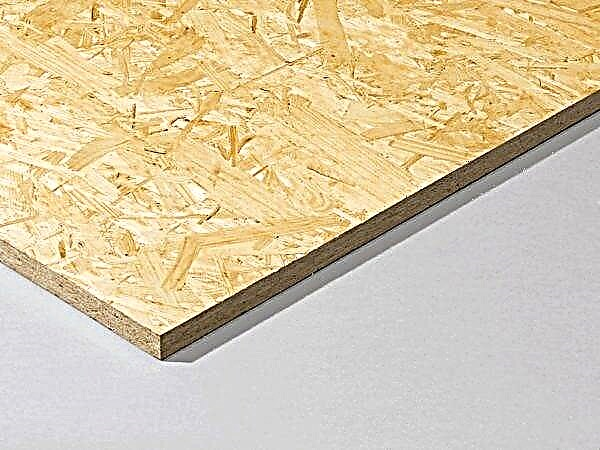

In OSB, chips or chips are stacked in three or more layers, and in each of them it lies in the same direction. In adjacent layers, directions are mutually perpendicular. This is the reason for the name, which translates as “oriented particle board”. Due to this design, the plate more resistant to bending forces.

OSB-plates, which tolerate bending forces well, are used in the decoration of the attic of complex design

OSB-plates, which tolerate bending forces well, are used in the decoration of the attic of complex design

OSB boards can be more or less moisture resistant. On this basis, they are divided into 4 categories. OSB-1 can only be used in dry rooms, and OSB-4 can be used in rooms with high humidity.

In both particleboard and OSB, the binder is phenol-formaldehyde resin, which emits harmful fumes. The extent to which harmful vapors are released is characterized by the so-called toxic emission class. There are four classes - from E0 to E4. For interior wall cladding in residential premises, it is allowed to use plates of class E0 or E1. In this case, the material should be covered by some kind of front coating, for example, wallpaper.

With great care, OSB-plates of Chinese manufacturers should be purchased, many of which unreasonably attribute low emission class to their products. There is a high probability that such material will have a strong negative effect on the health of residents.

MDF boards are also made of chips, but in some ways they differ from the two previous types:

- harmless paraffin and lignin are used as a binder, the latter being contained in the wood itself and released during its heating and subsequent pressing. This is, so to speak, natural glue,

- on the one hand, decorative cladding is applied to the plate.

MDF boards are recommended to be used as a front coating due to their environmental friendliness

MDF boards are recommended to be used as a front coating due to their environmental friendliness

- melamine film with a pattern that imitates the structure of a tree: it is cheap, but easily scratched,

- veneer, that is, a thin board made of valuable wood: it costs more, but in comparison with the film it is more durable and looks “more solid”.

Thus, MDF boards are absolutely environmentally friendly and can be used as a finish, while chipboard and OSB boards are used only as a rough one (they need to be covered with wallpaper, linoleum, etc.).

The width of the MDF panel may have different. It is advisable to use as wide as possible, since a coating with a minimum number of seams looks most attractive.

PVC panels

The PVC panel is a monolithic part consisting of two plates separated by stiffeners. Typically, these panels have structural elements that allow you to snap one part to another.

PVC panels are available in a wide range of colors, which allows you to implement a variety of design solutions

PVC panels are available in a wide range of colors, which allows you to implement a variety of design solutions

The advantages of plastic panels are as follows:

- low cost,

- water resistant

- smooth surface that is very easy to clean,

- a wide variety in both color and pattern - printed or embossed,

- softness and, accordingly, ease of processing,

- ease of installation: unlike other waterproof and smooth materials - ceramic tiles - can easily be laid by an inexperienced craftsman, so you do not have to invite a specialist from the outside.

But, despite the impressive list of "pluses", this material is far from ideal, it has several disadvantages:

- hazard of release of harmful volatile substances. Plastic, especially cheap, can emit harmful gaseous substances due to the decomposition of polymer molecules. For example, PVC emits chlorvinyl gas. With relatively little heating - in the range of 50–80 ° C - the amount of gas released increases greatly. This should be kept in mind when choosing recessed luminaires for a false plastic ceiling. The best option is LED lamps, which almost do not give heat. Heating radiators, heated towel rails and other heat sources must not be placed close to the plastic trim.

- fire hazard. Plastic is flammable, but it's not so bad. In the end, the tree also burns well. The main danger is that when burning plastic emits a huge amount of extremely toxic smoke. In contact with flame, even polymers with flame retardant additives, which are therefore considered non-combustible, liberally emit poisonous smoke.

- low strength. The plastic panel can easily crack even with a relatively weak impact with a hard object. If it does not crack, then it will be scratched. Because of this, the polymer lining quickly loses its presentation,

- the room, trimmed with plastic, does not seem cozy due to the cold unnatural shine.

To summarize, we can say that PVC panels are a low-cost alternative to ceramic tiles. Such decoration is usually used in places without a permanent stay of people where moisture resistance and hygiene are required: in bathrooms, hallways and on balconies. It is not recommended to use them when finishing the attic.

Drywall

Cheap sheet material used as rough sheathing. It is a gypsum sheet with a cardboard lining. The material is divided into several types:

- ordinary drywall sheets (GKL),

- fire resistant (GKLO),

- moisture resistant (GKLV),

- moisture resistant (GKLVO).

The properties of drywall allow you to build trim elements of the most bizarre shape

The properties of drywall allow you to build trim elements of the most bizarre shape

Sheets are produced with a thickness of 6 to 25 mm. For the manufacture of a false ceiling, a material with a thickness of 6–9.5 mm is used, for wall sheathing - with a thickness of 12 mm or more.

If you perform perforation in a cardboard cover with a needle roller, and then moisten a sheet of drywall with water, it will become flexible. Such a property makes it possible to make arches, multilevel ceilings with curved outlines, and similar structures from this material.

Do it yourself inside the attic

The process of arranging the attic can be divided into several stages:

- First, preparatory work is carried out, which is due to the fact that the entire rafter system after installation of the finish will be unavailable. Therefore, it must be carefully checked for rotten areas, cracks, corrosion of metal fasteners and other defects.

After the attic is equipped, roof leaks will also not be detected immediately, therefore, its condition must be carefully checked. If there are dubious places, they need to be generously treated with silicone sealant for outdoor use.

As a waterproofing, it is better to use a special membrane that does not pass water, but is vapor permeable. Due to this, water vapor entering the heat insulator will be able to exit into the ventilation gap located under the roof, therefore, the likelihood of condensation in the mineral wool will be practically zero. Just keep in mind that such a membrane works differently in different directions, therefore, you need to be careful to lay it on the right side.

Mineral wool, both glass and basalt, forms dust from fragments of its finest fibers. If it gets into the eyes or respiratory tract, this dust provokes serious illnesses. It is also advisable to protect the skin, otherwise there may be irritation. Therefore, the installation of mineral wool insulation is carried out with glasses, a respirator and gloves, and old clothes are worn, which after work will not be a pity to throw away.

In the case of using mineral wool, vapor barrier inside is not required, that is, the wall can be made “breathable”. At the same time, mineral wool is covered with vapor permeable waterproofing on the outside and then a ventilated facade is arranged: they are mounted on the siding brackets so that there is a certain gap between it and the insulation.

In the absence of a ventilation gap under the roof, even foam can be protected by vapor barrier, although it is moisture resistant. Otherwise, the steam will condense on the inner surface of the roofing, causing rotting of the wooden elements of the rafter system.

Attic device under a sloping roof

The owner of the house with a sloping roof has the opportunity to create an attic, no different from other rooms, that is, with vertical walls and a horizontal ceiling. Walls are formed as follows:

- On a floor racks from a bar are installed, fastening from above to rafters.

- Horizontal rails of the frame are nailed to the racks.

- The casing and, if necessary, the finishing trim are attached to the frame.

The easiest way to use the ceiling is to stretch, not forgetting, of course, to first insulate the roof.

Attic finish

Today, attic furnishings are estimated on average as follows:

- impregnation of the framework with an antiseptic (2 layers): 80 r./sq. m

- impregnation with an antiseptic of a block house, imitation of a bar or lining: 120 rubles / sq. m

- frame mounting: 120 p. / sq. m

- installation of a heat insulator: 100 rubles / sq. m

- wall cladding: clapboard, including plastic - 330 rubles / sq. m, block house - 430 p. / sq. m

- ceiling lining: clapboard - 400 rubles / sq. m, block house - 500 rubles / sq. m

- applying varnish or oil coating: 250 rubles / sq. m

- cladding lining: 550 p. / m. P.,

- installation of the plinth and corner: 120 p. / m. P.,

Total: finishing one square meter of the attic will cost 2070 rubles / sq. m with lining, 2270 p. / sq.m when finishing with a block house.

Video: DIY attic finishing

Turning the attic into a comfortable attic is available today to the homeowner with any income. The main thing is to remember when choosing finishing materials that many of them pose a threat to human health. Give preference only to well-known brands and make purchases in specialized stores, where the likelihood of running into a fake is minimal. It is also important to observe the construction technology - if everything is done correctly, the attic will delight the homeowner for many years.

Important Nuances

Arrangement of a mansard with a sloping roof is noticeably more complicated than a conventional building. If the builders are not well trained, they will not be able to do the job properly. In appearance, the roof structures are more like four-pitched roofs, the effect is formed due to a number of breaks and the placement of rafters in a couple of tiers. The lower rafter group is placed at an angle of at least 60 degrees, while the upper is mounted at angles of less than 30 degrees.

Equipping a wooden house with a gable roof is attractive because such a solution is practical when working and subsequent use to the same extent. To create an additional room, you need to think about the internal arrangement and the rational angle of the ramp. The minimum necessary conditions are preparation for working with wood and basic ideas about the engineering aspects of construction.

It is recommended to make a roof with a width of 500-600 cm to make the widest possible internal space.

The attic of the second type, made of SIP panels, is built very quickly and easily, while the created room will be warm enough even in the Russian climate. The advantages of their use are as follows:

- excellent thermal insulation

- minimal risk of destruction by pathological fungi and other microorganisms,

- immunity to fire

- lightness of the created structure - almost never there is a need to strengthen the foundation additionally.

Since any attic cannot be placed in an unheated part of the building, it will be necessary to take care of insulation to a much greater extent compared to the usual attic. A vapor barrier is necessarily equipped and a ventilation gap is left, a waterproofing layer is prepared. You cannot refuse to use any of the layers, because the function of each of them has a strictly defined function. On a properly insulated roof, the snow will not thaw and turn into ice.

Attic in small garden houses are mostly built on existing buildings. As a result of the alteration, the overall height of the structure is much greater than it was originally designed. If during calculations it turns out that the supporting base is not able to bear the created load, it is necessary to place additional columns. If the original supports are weak, it is advisable not to save time and money, but to disassemble the entire building and exchange the problematic elements with new ones, further strengthening the foundation.

The harness is made of reinforced concrete or expanded clay concrete, in execution it is similar to a crossbar, supplemented by a console. Under monolithic reinforced concrete, a formwork made of expanded polystyrene must be mounted. The use of high-tech off-the-shelf components helps to simplify the work and speed up its implementation.

Superstructures are always equipped with strapping belts that help to make the load distribution more even and tightly connect the new room with the main part of the building.

Training

Before you do the interior decoration with your own hands, you need to carefully consider the layout of communications, the geometry of the building and how the engineering systems of the house as a whole and the attic separately will interact with each other. It is impossible to use the attic for housing in the full sense of the word if it is not equipped:

- electrical wiring

- water supply networks,

- heat supply systems.

The first step in the work is always the manipulation of the overlap. Most often, a floating floor is used, requiring the creation of a thermal insulation layer of at least 4 cm and a dry screed. Moreover, the total thickness of rough floors is a maximum of 25 mm. Dry screed - usually gypsum boards or drywall sheets. Very uneven surfaces and deformations are leveled with vermiculite, perlite or expanded clay, the common layer of which is usually 50 mm. We must strive to ensure that the specific gravity is in the region of 25 kg per 1 sq. Km. m

The preparation of the walls should be carried out strictly after the roof and the pediment of the building are prepared and finished. The ramps are not sheathed immediately, a technological break is necessarily provided for the care of excess moisture. The exact time is determined by the humidity of the air and the materials themselves.

Laying a pipe (chimney) in the attic also has its own subtleties. There is no need to brick it outside, it is enough to apply the traditional solution:

- the chimney itself is made of stainless steel,

- a heater is applied (wound) on top,

- finally, an additional sheet or sandwich panel is mounted.

Such a solution is significantly cheaper than the blocks manufactured at the plants, and the quality with proper accuracy will be no worse. The inner pipe must have a diameter of 12 cm and it is installed in a larger pipe, the diameter of which is at least 22 cm. The bottom of the chimney is equipped with a tee for revision and condensate collection in order to simplify subsequent operation. Metal should be taken with smooth walls, corrugated structures will not work for this.

A very important topic in preparation is the formation of slopes of windows. Work with them has a number of differences from the formation of conventional facade structures. In the attics often windows are not equipped with gables, but with slopes, then it is required to make a multilayer roofing shell on their basis. If all the work is done efficiently, then:

- heat is stored as efficiently as possible

- the surface is not condensed,

- “Pie” retains its valuable qualities for a long time,

- windows open and lock freely as needed.

For every 10 square meters. m of the floor of the attic should be 1 square. m of glazed surface. To put the windows too high is not worth it, because this will interfere with the enjoyment of the external landscapes and will not allow you to evaluate what is happening outside the walls of the house. The required area of glazed blocks is almost independent of the placement height. Marking the inside of the wall is strictly required, when trimming the roof waterproofing, you need to leave 0.2 m around the entire perimeter so that an overlap appears on the future frame. All wooden blocks must be saturated with flame retardants and antiseptic substances.

It is necessary to process the attic from the outside (before installing the thermal insulation). Surfaces made of wood are impregnated with antiseptics, metal parts must be coated with an anti-corrosion compound. It is advisable to carry out all work, including the connection of insulation structures, in dry, calm weather. Before processing, all parts are examined carefully, parts damaged by insects or corrosion are immediately replaced, wet parts are dried in a natural mode.

Material selection

Strengthening structures, increasing their service life and even heat conservation are very important. But no less important is the optimal choice of materials for the front trim. It is by the impression he creates that they judge the aesthetic taste of the owners and the builders' ability to achieve the optimal result. Compared to plastic elements, OSB boards are much more perfect if only because this material is completely natural and effectively resists water. Even the best varieties of natural wood can not have the best indicators of strength and flexibility. Obviously missing:

- knots

- caverns

- curved fibers

- risks of swelling in contact with water,

- difficulty in slicing.

In the attic OSB is used because this material does not crack, it can be further improved by painting or gluing the surface with wallpaper.

Classic wooden structures continue to remain quite popular, because the main parts of the attics are mainly made of wood. And the coincidence of thermal expansion coefficients simplifies docking and increases the duration of the work. Using lining or imitation of timber, you can increase the level of thermal protection and create an attractive microclimate in the house. No other type of finishing structures, even the most advanced in technical terms, has such positive qualities. Lining has a number of unique profiles, sizes, installation methods, and therefore the appearance of the composition can be completely unique.

Using drywall, you can create various partitions, arches, columns and suspended ceilings. Adequate space in the attic is crucial. After placing such structures, you can paint them with various paints and varnishes or stick wallpaper.

Sheathing the attic with a profiled sheet is only necessary provided that this material is marked with the letter C. The external polymer coating is more reliable and stronger than the paint layer. Excessive surface relief is undesirable, because such a solution is very similar to covering a hangar or warehouse. It is recommended to immediately buy a professional sheet, which has already been cut into fragments of the desired size.

Extremely accurate geometry for setting the frame is achieved through the use of special facade brackets. For fixing these brackets, self-tapping screws (on top of wood) or a dowel nails (when the base is brick or concrete) are used.

Many finishers use plywood, because this material is cheap and relatively simple to use. With its help, it is possible to even even extremely curved bases and prepare an attractive basis for subsequent design. The only difficulty is that plywood is not suitable as a finishing material, it is not attractive enough. Its disadvantages are the same as that of wood as such.

As for MDF, its installation is not very different from working with drywall sheets. But there is no special need to form a special frame with strictly defined distances. If the frame is nevertheless made, a timber with a section of 4x4 cm is taken for it. You can improve the appearance if you use hinged decorative elements.

Decor

Plasterboard casing can be placed inside the attic both to form the original appearance and to cover elements that damage the appearance. Also, this material is suitable for dividing space into separate rooms through partitions.

Using a block house, it is possible to design the attic space in an ecological style or in the spirit of old Russian plots. But in order to increase the service life of the products, it is advisable to impregnate the tree with a special composition. The block house has good contact with water and is not prone to mold.

Walls

If the walls of the attic floor are sheathed from the inside with an imitation of a beam, you can easily solve three main tasks in the decoration - such as creating an elegant interior, leveling the surface and masking significant defects. Like lining and wood-fiber boards, this material retains heat well.

Outside, the most budgetary type of attic decoration is siding (if you focus on materials at the same time beautiful and long-term employees that do not require complicated maintenance). In the process of laying, it is required to take into account temperature fluctuations and the changes in the size of structures caused by them. To avoid errors when arranging start elements and connecting panels to them, It is recommended to draw up drawings as carefully as possible.

A solid competition to all these decisions is the half-log, which, after installation, is necessarily ground and varnished with water-based varnish. To put such a product in the opening for a door or window, the desired configuration of the corresponding face is attached with a chainsaw. Combined trim is fairly common, during which lining and drywall are combined, for example.

The floor on the attic tiers is best finished with a laminate or other materials that ensure absolute tightness of the structure. To begin with, the rough surface is treated with special waterproofing compounds, and the intersection of the blocks is glued with a tape impervious to water. Then 100% of the area is covered with a primer, and only after that it is possible to lay boards or other materials selected for final finishing.

Ceiling

The arrangement of ceilings in the attics begins naturally with their insulation, while mineral and glass wool are considered the best materials. In houses that are already in operation, the insulation layer is laid only inside. At the initial stage of construction, it is placed on the outside in rafter gaps or on the crate. The outer face coating is mainly made of:

There is much more variety of methods of interior decoration, but the decisive factor in choosing a particular option is not so much aesthetic perfection as cost.

New ideas and design options

The best designers are ready to offer the best ways to decorate the attic rooms, but it’s much more economical not to contact specialists, but to apply ready-made, proven approaches. The photo shows a staircase with decorative carved elements - special railing. Against the background of a wooden house as a whole, such a solution looks very, very good. But only if the color of the room is as bright as possible.

Many attics are glued with wallpaper from the inside. Here is one such example - the fact that the wallpaper used to cover the walls is difficult to guess, they have such a uniform and unexpressed color and texture. Even an old-fashioned TV between two windows attracts a lot more attention.

When arranging a summer residence, many land owners also resort to the use of attics. Here is one of such solutions, in which a number of atypical design moves are used - what is at least a wall covered with family photographs worth, or a moose head model placed on top of a lamp. About the design perfection of the interior speaks at least that how vivid color accents are placed at individual points in the room. The floor of exquisite light brown linoleum is perceived, of course, positively.

In the attics, bedrooms are often made, and the number of beautiful options is simply huge. Here is an example of how a “hanging” red wall harmoniously combines with a red accent blanket on the bed, and due to the exact formation of the composition, everything looks very attractive. The wall opposite the bright strip is painted in various shades of black and white. The requirements for the selection of composition for painting the attic are the same as in other parts of the house (protection from moisture, from sunlight in certain situations, and so on).

You can find out how to equip the attic in the next video.

Types of finishes

For the attic floor, as well as for any other room, the decoration is a whole complex of events. In general, it can be divided into several stages:

- wall decoration

- ceiling finishing work,

- finishing work of the floor.

For finishing it is not necessary to attract specialized workers. These works are quite possible to do on their own.

Painting the attic ceiling

Painting the attic ceiling

The following materials are most often used for decoration:

- drywall sheets,

- lining

- plywood,

- OSB boards,

- blockhouse and others.

Decorating the walls and ceiling of the attic with plasterboard

Decorating the walls and ceiling of the attic with plasterboardThey are used both for walls and ceilings, although the latter also uses the technology of stretch ceilings, seamless stretch ceilings made of fabric or bamboo ceilings.

Cladding the attic

Cladding the attic

Each of these options for the attic floor does not require special knowledge or devices for decoration. Materials have a sufficient level of strength and durability.

Blockhouse, plywood, siding

Lining is not the only wooden type of material that is used for decorating both the attic and the other floor in the house. Currently, plywood, siding and block houses are no less popular. In addition, some of them have significant advantages in appearance. For example, the walls lined with a blockhouse look as if they were lined with a real round timber.

Decorating the attic with a blockhouse

Decorating the attic with a blockhouse

Plywood and siding, in contrast to the blockhouse, are more economical. Finishing work with such materials is carried out with a minimum amount of financial costs and with little time. However, plywood is convenient in that it comes in the form of sheets, as well as drywall. Therefore, installing it is much faster than, for example, lining boards or a blockhouse. As fasteners, nails or self-tapping screws are usually used.

Attic plywood finish

Attic plywood finish

After the room is completely sheathed, you can hide it with varnish or use paint. Recently, designers have recommended using two primary colors to make the room stylish and original.

Covering the block with a house

OSB plate as an option for finishing work

These boards are ideal for those who do not like drywall and wood materials. OSB is better than drywall in the sense that these slabs are not subject to deformation (meaning crack formation). But, at the same time, the surface of these materials is completely flat.

Wall decoration inside OSB boards

Wall decoration inside OSB boards

Before proceeding to the finishing (wallpapering, painting or fabric finishing), OSB boards must be primed.

However, it is necessary to paint such a plate carefully, because due to the influence of moisture, it can deform (bend).

Interior decoration of the attic with OSB boards

Floor finishing work

Sex requires special attention. Here, not only you need to choose high-quality materials for finishing work, but also for insulation. After all, it is the protective layers of insulation and waterproofing that guarantee the long service life of the floor covering.

Attic floor insulation

Attic floor insulation

As the material for the floor, it is best to use conifers - pine, larch and fir.

Boards (necessarily dry) need to be laid on beams.If they are not dried before laying, after they can become narrower and gaps will form between the boards.

Also, an important step is the processing of wood from moisture, fungi and insect pests. Nails are used as fasteners.

Laying plywood on the attic floor

Ceiling work

A variety of materials are used for the ceiling, depending on the preferences of the owners of the house:

- drywall

- suspended ceilings (PVC film, fabric),

- lining

- plywood,

- OSB, fiberboard, particleboard boards.

All of the listed materials, in addition to suspended ceilings, are mounted in the same way as when walling.

Blockhouse attic ceiling

Blockhouse attic ceiling

PVC films and fabric cloths for the ceiling - a solution for the interior in almost any style. The frame for their device can be made for almost any surface, including pitched. Thanks to this, the film will completely repeat the shape of the roof.

Attic stretch ceiling

Attic stretch ceiling

Another advantage of this method is that the device of such a ceiling practically does not hide the usable space. In addition, the film will protect the interior of the room from leaks, because it does not leak liquid at all.

Attic stretch ceiling design

Attic stretch ceiling design

Decorating plays a crucial role. If the materials are chosen incorrectly or the technology is not followed during their installation, the room will look awkward. The most common options for decoration are sheets of drywall, OSB, plywood, particleboard, fiberboard. In addition, natural wood trim does not lose popularity, which, in addition to looking spectacular, is environmentally friendly. For the ceiling, in addition to traditional options, you can use tension systems, which have a lot of designs and will suit any interior.

Ksenia Skvortsova. Chief Editor. Author.

Planning and distribution of responsibilities in the content production team, work with texts.

Education: Kharkiv State Academy of Culture, specialty "Culturologist. Teacher of history and theory of culture. " Experience in copywriting: From 2010 to the present. Editor: since 2016.

The lining of the attic with a wooden lining gives the room coziness and warmth.

The lining of the attic with a wooden lining gives the room coziness and warmth. MDF boards are recommended to be used as a front coating due to their environmental friendliness

MDF boards are recommended to be used as a front coating due to their environmental friendliness The properties of drywall allow you to build trim elements of the most bizarre shape

The properties of drywall allow you to build trim elements of the most bizarre shape