Most often, tiles are used to decorate the fireplace.

You can trim the hearth not with solid tiles, but with pieces like mosaics

The material will not be affected by the heat of the oven and draft. Additionally, it is characterized by the following advantages:

Allows air to circulate inside the surface without creating obstacles.

Tiles have a high degree of heat transfer

- Long service life.

- It is made from natural ingredients.

- When heated, does not emit an unpleasant odor.

- Among a wide range of products, you can choose the right one for a particular room in the house.

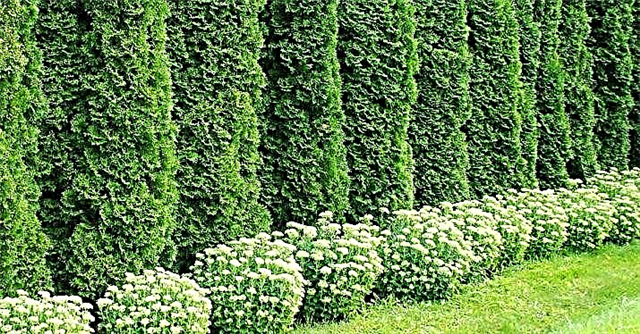

Natural or artificial stone is used in rooms with a classic design style. Most often, in order to clad a fireplace portal, granite, marble, shell rock and slate are used. The material is of high cost, so it is not used in budget options for living rooms.

Natural stone finishes found in country style

The stone should be selected based on the following advantages:

- The texture does not deteriorate when exposed to heat.

- Eco-friendly and durable.

- Easy installation.

- Creates a unique and unique piece of furniture.

A brick fireplace is a classic version that looks advantageous in any interior.

Brick is not afraid of high temperatures, so it will last for a long period of time.

Porcelain tile is a natural material that looks like a natural stone. It owes its unique operational properties to the presence of a minimum number of pores in its composition.

Porcelain stoneware fireplace fit into high-tech, art deco, eclectic and other styles

Buyers opt for it also because of the following advantages:

- High strength.

- The cladding will not be affected by an open flame. It will retain its structure even in conditions of high humidity and in frost.

- Environmental friendliness.

- A wide range of colors and textures.

- Simple operation.

Plastering is considered a budget option, because it does not require significant financial investments. With its help, you can create an externally attractive corrugated surface. Suitable for corner fireplaces.

Stucco finishes perfectly with minimalism.

Today, it has become possible to clad a fireplace with a tree.

The fireplace portal can be decorated with wood

The material not only has unique aesthetic properties, but also produces a pleasant aroma when heated. The owner will need to purchase breeds that are resistant to this type of external influence. The best option is oak, hornbeam, maple or cherry.

In an ordinary apartment, a real fireplace cannot be made, but it’s easy to assemble a budget version from drywall

Giposkarton can be used as a facing option only for an electric fireplace. During operation, safety precautions should be observed. Otherwise, the structure may catch fire.

If a person has a minimum budget, then he can decorate the room with a false fireplace. For its design, you can choose any materials.

Certain restrictions in this area do not exist. You can make both a real and a false fireplace.

Features of fireplace inserts (interior decoration)

When they decide how to decorate a fireplace, the design of its firebox matters

If you are interested in how to decorate a fireplace, you should also learn about something else: what is a firebox. By the fireplace, this is the place where solids burn - it can be wood, coal or some other fuel. Decorative fireplace decoration also includes work with the firebox, but more on that below.

To finish this part of the structure, today they use:

- Brick,

- Drywall Sheets,

- The stone is natural.

Drywall cladding

You can really use drywall sheets to sheathe a fireplace insert (after all, such material can even be laid on the floor - it is durable). But, only if the work is carried out with a false fireplace. However, exceptions to the rules are also allowed. Drywall may be necessary if it is necessary to level the surface in the furnace,

Only a special material can be used in works of this level - moisture-proof drywall

They don’t recommend using any other here,

In the process, it is also worth paying attention - if such a material is used, the volume of the furnace can be significantly reduced. This is because the fastening of the sheets is performed on the frame (of course, metal)

It is made of a special profile on the surface.

What is used in order to perform installation work:

- Need material directly

- Metal profile,

- Screwdriver and screws.

And now in detail about the installation:

In the course of work, some difficulties may arise - especially their probability is high when there are places in the fireplace that are difficult to access. That is why it is recommended to work with a screwdriver (a tool that functions with batteries),

A fireplace insert with gypsum board is usually sheathed when the size of the furnace needs to be reduced - to a large extent

This happens when the fireplace is large - and the owner wants to correct the situation,

If you decide to use sheets of such a material, it is important to think about the interior decoration in advance - so that the material can be protected from the damaging effects of fire and high temperatures.

Facing with wood or decorative stone - solutions that will always be relevant for structures of this type

This will definitely help you:

- The stone is decorative

- A natural stone,

- Ceramic tile (not often used, rather the exception).

We use a brick

Fireplace bricks are also often used.

Typically, brick is used in a situation where the fireplace itself is built from this material. In this situation, the firebox is being erected along with the rest of the structure; there is no need for additional decorative decoration.

In addition, the brick is chosen in the case when the entire fireplace structure was made of another material - which can not cope with temperature influences (or simply easily ignites, does not tolerate heat).

Such materials are:

- Wood,

- Drywall which is not fire resistant.

A chimney is laid out of brick, the firebox itself is inside the structure

And to ensure maximum safety, it is important to maintain a certain distance from the fireplace box to the facing brick layer. This interval should be at least 200 (or even better - 250) mm

Facing with ceramic tiles

Ceramic tile - another option worthy of attention

If the decorative decoration of the fireplace is exactly what interests you, you can not pass by such a wonderful material as ceramic tile.

In general, it is rarely used for interior furnaces of fire chambers, they are attached only to that surface that is flat (usually on drywall, it’s already been understood that installing it is not such a difficult task).

You can easily install ceramic tiles if you have at hand:

- Concrete mortar

- Two spatulas

- The finishing material itself,

- Cross-shaped plastic beacons (needed to ensure that the seam is even).

Features of the use of ceramic tiles:

The material is very fire resistant. To perform the installation efficiently, it is best to use a special building glue or concrete mortar.

Features

The decorative look of the fireplace can play a major role in creating the interior indoors. The fireplace is used not only as a decoration, but also as a source of heat. In this case, you need a special approach to the choice of material from which the furnace will be made. Marble is a great option.

The raw natural rock of marble is practically no different from other fossil materials. In the processed state, the marble product acquires a unique pattern and elegant colors. Marble fireplaces can differ significantly, because the design elements are very diverse.

Experts recommend the use of marble for decorating a fireplace due to its natural characteristics.

- Environmentally friendly material that is not harmful to health. Even when exposed to open flame does not emit toxic substances.

- High strength products that can withstand heavy loads.

- Resistant to high humidity.

- Fire resistance of the material. When exposed to open fire, marbled stone surfaces remain protected.

- Unlimited service life (about 100-150 years). Replacing the facing material occurs only if the appearance of the product dims or becomes unnatural.

In addition to all the positive characteristics, marble also has negative aspects. Mining and processing of stone is carried out for a rather long period, therefore, the cost of marble products will be high.

Thanks to the existing methods of lining the fireplace with marble, specialists can develop unique images in the design. By grinding, the volume and structure of marble stone can be emphasized. The aging effect brings the appearance of the stove closer to ancient times. Stone polishing enhances the natural qualities of marble, as well as the reflection of a blazing fire.

Ceramic Tile - Proven Material

When the question arises, what should be faced with a fireplace, the first thing that comes to mind is ceramic tile. It differs in technical characteristics from that used to design bathrooms and kitchens.

The product must necessarily be resistant to temperature and temperature extremes, as well as to give heat well. Clinker can also be refined with clinker, chamotte, tiled, porcelain tiles.

The use of decorative tiles in such works has several advantages:

- Materials for the fireplace are offered in a wide range, differing in price, quality, texture, color and other parameters.

- Each species is resistant to high temperatures.

- Subsequently, the design will be simple in household care.

- You can decorate a fireplace in any stylistic and design direction.

- The masonry process is as simple as possible.

Tiled finishes

You should know that fixing the tile to the surface of the fireplace occurs with the help of a special glue that does not soften when exposed to high temperature. In most cases, the stove is faced with small products, which in the future reduces the likelihood of deformation and cracking of tiles.

To implement the design, tools and materials for fireplace mantels are pre-prepared:

- Check the evenness of the vertical and horizontal lines using the building level and plumb.

- To mark using a marker, or a simple pencil.

- An adhesive base is applied with a spatula.

- Use a rubber mallet to press the material to the surface.

- The front part is cleaned with a sponge.

- To make the seam even and separate the elements, crosses will be needed.

- Grout and a rubber trowel for applying it will also be required.

If you need a step-by-step instruction of work, then it looks quite simple:

- Initially, the joints are laid out for the main masonry of the fireplace.

- Then carry out cleaning from dust and dirt.

- The decoration of the fireplace in the next step involves the processing of a soil mixture.

- If necessary, tighten the structure with a metal mesh.

Facing the fireplace begins with the fact that the tiles are laid out on the floor near the structure, and if necessary, materials are carefully adjusted, which will make it possible to clearly see the future pattern. After that, the fixing material, the adhesive is diluted with water in the proportions specified in the instructions for the composition.

Light portal design

Starting from the lower zone of the furnace, the first row of tiles is laid out. To do this, take the solution, apply it to the surface of the fireplace and pass along it with a notched trowel. After they apply the tile, press it and tap it with a rubber mallet. Using a level, check the conformity of the masonry plane. The next row is laid identically, and the aisle is filled with crosses in the corner zones of the tile.

There is a corner tile material for decorating the fireplace, with the help of which protrusions are laid out. When the construction is completed, it must be left until the glue has completely dried. In order for the product to collect less dust and soot, it is coated with a special varnish.

Solution preparation

The fireplace, tiled with ceramic tiles, will serve for a long time only if you have applied a quality mortar. If the fireplace is decorative and does not have a firebox, then everything is simple: you can mount even on a dry mixture.

If the fireplace is working, then you should approach the issue much more seriously. The surfaces will bond best if the masonry and tile fixing solutions have a common composition. It can be clay or cement.

Clay solution

This mixture is most suitable for an existing fireplace or stove. It can withstand both temperature extremes and high humidity.

Therefore, it does not matter what type of fuel is planned to be used for the hearth furnace

Clay solution must be plastic

Such a solution incorporates sand and clay. And to determine the required percentage composition of the components, you first need to determine the clay fat content. To do this, we make a dozen balls of clay and sand in different proportions. We let them dry completely and from a height of one meter we simply drop them onto a hard surface. One that has not deformed and has not crashed will have the correct composition.

- Pass the clay through a sieve and separate the garbage and knead the lumps. The composition should be homogeneous.

- After determining the composition of the solution, we knead. To do this, it is best to use a container without stiffeners along the edges and bottom. Pour clay into the container and fill it with water. We give her after that infuse for a day. It should turn sour and gain the desired viscosity.

- After that, add sand in the right amount and mix. To do this, use a drill with a nozzle. So we can most quickly achieve uniformity of mass.

Cement mortar

Such a mixture is much easier to prepare. However, it should not be used if solid fuel is used for the fireplace insert:

- For its preparation, sand and cement are used. For M300, a 1/3 composition is used.

- First, pour sand into the container and then add cement in the required amount.

- Mix dry until even. Add water and mix again.

- To make the mass homogeneous, you should use a drill with a nozzle.

English-style hearths

English fireplace - Mr. impeccability. It is laid out in a U-shape and endowed with classic features. In design, priority is given to straight lines and smooth, clearly angled corners. The furnace itself is small, but voluminous. The accent area in the furnish of the furnace makes a large portal. It is decorated with tiles, forging elements, expensive wood.

English style fireplace decor

Hearths in the style of provence

No frills, no pomp - just the simplest forms. Creating such a fireplace, its design is worked out in the smallest details.The color scheme of the fireplace decorative decoration is certainly in a calm shade. Ideally, the focus is made in white, although the light calm colors of the portal of the green, blue, yellow spectrum will fit well into the interior composition.

White fireplace in Provence style

A good solution is to age the paint, giving it a faded look. You can venerate the fireplace with stone Provence or ceramics. Wood, although not alien to style, is not so common in the decoration of a fireplace of this type. If it does appear, then only precious breeds. Forged parts can become the decor of the furnace.

Provencal style wood trim

Country-style hearths

Fireplaces of a rustic style, with all their simplicity and simple decoration, become real carriers of home comfort. They are heavy and have impressive dimensions. For this reason, the construction and decoration of the fireplace with their own hands is difficult.

Massive country style fireplace

Portals are issued in a D-shaped form. The hearth has a niche under the firebox, where the kindling firewood is added. A powerful beam is laid above the firebox, most often from a stone monolith.

A country oven can be made not only wood-burning, but also gas-fired. It is recommended to decorate the portal with artificially aged sandstone, masonry, shell rock.

Brickwork perfect for country style

Ethnic-style hearths

Ethno-fireplaces are distinguished by species diversity. They can be interpreted in a strict Old German, Scandinavian style or presented in bright Indian color.

The decoration of the fireplace is responsible for ethnicity, which will give rise to the need to look for specific elements for its decor. They will help to associate with the chosen stylistic direction. As an option for furnishing the furnace, chalky whitewashing, stone, and clay mortar can be considered.

Ethnic motifs in the decoration of the fireplace.

The fireplace can also appear in the form of a virtually open hearth, which almost unfolds in the center of the living room like an ordinary fireplace.

Hearth in the ethnic style in the interior

Hi-tech hearths

Innovative materials, advanced technologies, shocking solutions - these are the leading landmarks in the decoration of hi-tech fireplaces. They can be created in the form of a coffee table, prism, suspended by a fireball on a metal chain. Such stoves can stand on the floor, hang on the ceiling, fasten to the walls. Often these are rotating and mobile interior elements.

High-tech fireplace

The decoration of decorative fireplaces may combine incongruous, for example, fire and water.

The material of manufacture is metal, refractory glass, characterized by high heat transfer.

Metal and glass - the best option for a high-tech fireplace

Hearths in the classical style

The stylistic visions of the fireplace decoration are absolutely identical to the basic principles of classicism: geometric clarity, straight lines, neutral color design. To add to the focus of respectability, its portal is decorated with unobtrusive stucco compositions and moldings.

The stucco molding will add a center of respectability

A classic fireplace may contain elements typical of baroque in its decor. In work on the image and furnish of the furnace, columns, forged protection elements can be used.

Classic fireplace in the interior

Stone fireplace mantel

Stone fireplace mantel

Do you want your fireplace to look truly elegant and chic? Then pay your attention to the stone finish. Natural facing stone is characterized by excellent performance and fits perfectly into any interior

If you have access to specialized equipment, you can independently pre-process and install marble or granite. In the absence of the necessary devices, give preference to shells, limestones and rubble stone.

Marble fireplace portal

Marble fireplace portal

The artificial stone does not seem to have noticeable differences from the natural finishing material. It can also be safely used to decorate the fireplace.

Stone fireplace

Artificial stone can be made with your own hands. To do this, mix cement, sifted sand and coloring pigments of the desired color and fill the resulting composition in silicone molds. Allow the mortar to harden in the molds, remove the resulting products and use them to decorate the fireplace.

DIY artificial stone

Mold for making decor

Directly facing is performed in the same way as in the case of natural stone, and when using an artificial analog. It is enough to fix the elements on the surface of the fireplace using mastic or tile glue. You can pre-lay the stones on the floor to see the future finish and choose the most optimal option for placing stones directly on the surface of the fireplace.

Stone finish, pattern

Tile finish

For this method of cladding, a heat-resistant material with a high level of thermal conductivity will be required. Porcelain tiles or clinker tiles are suitable. To avoid cracking, it is advisable to take small plates and fix them to glue with a high level of heat resistance.

Fireplace decoration options and its decorative ornaments are varied in the created patterns and patterns.

The advantages of the material include:

- ease of installation

- undemanding care

- resistance to high temperature conditions,

- variety in color and texture.

At the beginning of the facing work, it is necessary to prepare a standard set of tools. The surface should also be treated. All seams of the masonry are embroidered, the walls of the fireplace are cleaned of contaminants and treated with a primer. To strengthen the structure, it is necessary to make reinforcement by fixing the grid with screws.

To lay the tiles, a solution of water and heat-resistant glue is prepared. Work begins at the lower level. The glue is applied to the wall based on 3-4 plates and leveled with a spatula. After attaching the tile, you need to tap on it with a rubber mallet and check the level.

It is interesting: Decorative fireplace - we create homeliness

Interesting options for decorating fireplaces (photo)

All of the methods described above can be combined, creating a finish in different styles. Sometimes it turns out very beautifully. Some already implemented ideas are laid out below.

Very interesting fireplace design

This option will fit into modern styles.

Mosaic decoration of the fireplace is especially good on round shapes, where other materials are very difficult to apply.

Combinations of different types of artificial stone with wood fragments

Tile trim of fireplace portal and exhaust pipe

Plaster and tile combination

There are two options to achieve this effect - paint the existing brick fireplace or clinker tiles

This is polished porcelain stoneware.

This porcelain tile is unpolished, small format. As you can see, it fits well in rounded shapes. Horizontal surfaces and columns - also porcelain tile of a similar texture, but already in the form of plates

Design version of the cap and trim

Stone fireplace lining can be done on the street.

Terracotta in combination with a wooden shelf repeating the relief of the tile

Smooth brick tile - strictly and functionally

This is a stove Czech tile. Mounted on special racks

Majolica looks very decorative

Custom design

Plaster and tile combination

Tile inserts - beauty

Insulation options

There are many non-combustible materials that can be used in this case. The easiest way to protect all surfaces from heating is to lay a protective box around a red brick heat source. It is able to protect structures from heat and easily tolerates thermal effects. However, such a wall decoration around the stove in the house does not look aesthetically pleasing and other materials can be selected:

- Porcelain tile and tile.

- Fiber cement boards.

- Factory-made protective screens.

- Metal sheets.

- Artificial or natural stone.

The easiest way is to work with a ready-made protective screen - you just need to pick it up in size and mount it in place. This option is also good because such a wall decoration near the stove or fireplace is made in the shortest possible time and without "dirty" or "wet" finishing work. Other options are more time-consuming and have some nuances. Therefore, they need to be considered in more detail.

Technology decorative cladding, how to properly cover

There is a separate technology for mounting each material. If a tile was selected, then you will first need to carefully prepare the surface. Before fixing the tiles, it is thoroughly wetted with water.

It is possible to revet both a real, and a false fireplace

If there is a roughness on the surface, then it will first need to be eliminated by using plaster. This method allows you to quickly and effectively get rid of chips. You can go directly to the laying itself only after the base has completely dried. In this case, the technology directly depends on the desired thickness of the seams. Experts recommend them do more. Thanks to this, it will be possible to compensate for the difference in thermal expansion. If there are no special crosses, then pieces of ordinary drywall are quite suitable. However, their thickness should not be less than 9.5 mm.

Glue will need to be applied to each tile

To obtain an even layer, use a spatula with teeth. The tile is pressed to the surface and slightly swayed from side to side. The distance between the individual fragments will need to be set using previously prepared fragments. They should be removed only after complete drying. The process is guaranteed to complete in four hours. Tiles on the fireplace must not be touched until it is completely dry.

The length of the period depends on weather conditions and the quality of the adhesive composition. At the last stage, you will need to fill the seam. To do this, it is recommended to use a composition of the same company as the adhesive for installation. This will help to minimize incompatibility issues.

To dilute the filler, you need to add the powder to the water and evenly distribute it on the tile. The process is conveniently carried out using a spatula. Thanks to this, it will be possible to form a beautiful seam. To eliminate the excess, it is recommended to use any material.

Lay cellophane on the floor for the duration of the work so as not to stain it during the facing of the fireplace

To obtain a beautiful surface, it is recommended to use the following tips:

The tile will fit snugly if you first fix the metal mesh to the wall. Such a wire frame will increase adhesion and level the surface.

To eliminate excess adhesive, it is recommended to use a rubber spatula.

Before starting the process, the tile is laid out on the floor.

Excess mortar during masonry should be removed immediately.

Remove glue immediately, after hardening it is difficult to clean it

When laying tiles under the material should not remain air cavities. When heated, they will expand. Such a process will lead to the lag of individual fragments or entire blocks and will have to be overlaid with finishing material again.

It’s not difficult to lay down the fireplace yourself. A wood-burning fireplace is used to create warmth and comfort in a house, apartment. Around it you can gather on a cold winter evening. You can also make firewood for the fireplace yourself.

Fireplace materials

The lining of a wood or gas fireplace can only be carried out using fire-resistant materials and a mortar having a coefficient of thermal expansion similar to a brick, otherwise the lining layer will begin to recede and crumble over time. Most often, the fireplace lining is performed using such materials:

- Clinker or terracotta tiles made of baked clay,

- Natural or artificial stone,

- Porcelain tile.

Facing technology depends on the selected material, and in order to better understand which material is right for you, we will consider in more detail each of the types of finishes.

Ceramic tile: terracotta and clinker

The baked clay tile is similar in composition to the refractory red brick, from which fireplaces are usually laid. Thanks to a similar structure and manufacturing technology, ceramic tiles expand when heated together with the fireplace material. The top layer of ceramic tiles can be additionally coated with glaze, which will give it water-repellent properties - this finishing material is not afraid of water that accidentally hit the fireplace, or soot, which is easy to wash off from a smooth surface.

Photo - fireplace trim with ceramic tiles

Ceramic tiles come in different shapes and sizes; they also produce elements for facing ledges, corners, and shelves. The color scheme of terracotta tiles, as a rule, is close to natural materials. Laying the tiles is quite simple and does not require the use of a special tool, fitting and cutting is carried out using a grinder with cutting and grinding wheels.

Tiles can be placed on a special heat-resistant adhesive designed for stoves and fireplaces, or on a clay solution with sand and the addition of salt - 100-200 grams per bucket of mortar. Salt gives the solution greater plasticity, which eliminates its cracking during the combustion of the fireplace.

Technology of laying and finishing with tiles:

- The surface of the fireplace is cleaned of the old cladding: whitewash, plaster, paint. Stitch the seams between the bricks 1 cm deep, after which the dust is removed with a brush. The surface of the brick can be moistened with a spray gun.

- In the presence of small irregularities and indentations, they are covered with heat-resistant mastic or clay mortar, and then dried.

- If the quality of the brickwork is low, and the layer of mortar for laying the tiles is more than 5 mm, it is recommended that the surface of the fireplace be pre-leveled using an grinding wheel.

Grind the surface of the fireplace

Laying tiles on the fireplace

Check the glued tile by level and plumb

Fireplace grout photo

Fireplace decoration with natural and artificial stone

Natural stone used for facing fireplaces is an expensive pleasure, especially when it comes to marble or granite. To process these materials, you need a special tool, especially for granite, which is difficult to cut and grind, as well as special skills. A simpler stone: shell rock, limestone, rubble stone, it is quite possible to use it for facing the fireplace with your own hands.

Artificial stone - Portland cement based finishing material, in which the filler is a crumb of natural stone, expanded clay or other solid component. An artificial stone is obtained by vibrocasting or vibrocompression, as a result of which it is not inferior to natural in strength and moisture resistance. Artificial stone can have a completely different texture and color, which allows you to create a unique fireplace design.

Photo - fireplace decoration with artificial stone

The technology for laying natural and artificial stone is almost the same. They are placed on heat-resistant glue or mastic, and especially heavy stones are additionally fixed to the anchor.

- Preparation of the surface of the fireplace is carried out similarly to that given for terracotta tiles. The brickwork is cleaned, the seams are embroidered and dust is removed, and irregularities are leveled.

- Before laying, the stone is sorted by color, with different tones, they are completely laid out on a flat surface and stones are numbered.A darker stone is best placed in the lower rows. If necessary, the stones are cut with a grinder with a circle on the stone, polished sections.

- The fireplace is heated with a slow flame and cool its surface to 30-35 degrees. The brick is primed and dried for half an hour.

- The glue is mixed in the specified proportion until smooth. Stand it for 10-15 minutes and mix again.

- The masonry start the corner from the bottom row. The glue is applied with a spatula in an even layer on the stone, it is applied to the wall of the fireplace and rubbed tightly, turning and slightly shifting to the surface. Excess mortar may appear from under the stone, if they do not protrude above its surface, they do not need to be removed. The next stone is laid, leaving a seam of 2-5 mm. So they put the entire bottom row, checking it by level and plumb.

Masonry is checked by level and plumb

Beautiful fireplace trim with natural stone

Porcelain Tiles

Porcelain tile is a durable finishing material with a wide variety of colors. When decorating with granite, you can achieve the effect of facing the fireplace with marble, granite, coil and other valuable types of stone. At the same time, the price of porcelain is much lower, and its processing is simpler.

Porcelain stoneware fireplace decoration - photo

Facing the fireplace with granite is possible both on adhesive solutions and on a frame made of a metal profile. Glue laying technology is generally similar to terracotta tiling of a fireplace, so we will dwell on the second option - fixing porcelain stoneware on a profile frame.

- For the manufacture of the frame, a profile for drywall is required. It is installed around the perimeter of the fireplace so that porcelain tiles fit onto the profile. The frame is fixed to the fireplace in several places using anchor bolts, the profiles are fastened together by self-tapping screws for metal.

- Porcelain tiles are attached to profiles using special brackets.

Staples for fastening porcelain tiles

This method of cladding is good for fireplaces with a large number of chips, uneven masonry, extremely unattractive appearance. It allows not only to give the fireplace a new look, but also to smooth out all the masonry flaws without any special expenses.

Porcelain fireplace trim picture

There are other ways to decorate fireplaces and stoves: plaster with subsequent painting, tiling, mosaics. Knowing the technology of decorating and facing the fireplace, you will surely choose a design to your liking.

What should be the facing of the fireplace?

Since there are many options for the fireplace, it’s difficult to name the ideal finishing material. It all depends on a lot of factors.:

- type of fireplace. The material for the wood fireplace should be selected as carefully as possible, given the constantly acting high temperature. If you decide to stay on an imitation of a fireplace with candles or on an electric version, then the requirements for decoration will not be so strict.

- fuel type. The combustion temperature of different types of fuel is different, which must be taken into account when analyzing the parameters of finishing materials. For example, if you intend to use firewood, it is important that the cladding can withstand temperatures of about 900 0 С, but if we are talking about coal, it is better to take a material that tolerates temperatures of the order of 1100 0 С,

- place of installation. If you are going to install a fireplace on the terrace, it is important that the material has excellent frost resistance. Provided that it is used in a heated room, such a requirement is not advanced. If the fireplace is located in a house where only occasionally, then pay attention to such a parameter as moisture resistance,

- material weight. Too heavy material (for example, natural stone) may require strengthening the foundation, which is only possible in a private house and when installing on the ground floor. If it comes to an apartment or the upper floors of a private house, then you should definitely consider what kind of load the ceilings can withstand,

- appearance. Cladding is also a cladding to decorate a fireplace, therefore, when choosing a material, it is worth considering its appearance and compliance with the chosen interior style and color scheme.

No. 1. Fireplace mantel

Tile is the most popular way to decorate a hearth. You cannot use ordinary tile - it will not withstand the high temperature. As a rule, these types of ceramic tiles are used for facing a fireplace:

- terracotta tile It is made from fired clay, it has a beautiful natural reddish tint. In most properties it resembles a refractory red brick, from which fireplaces are laid, so when the temperature rises and falls in the furnace, the tile will expand with it. Terracotta tiles have a smooth coarse-grained structure. Additional pigments are not used in the manufacture, but the natural range of shades ranges from light brown to almost black,

- majolica It is also made from burnt clay, but it is covered with painted glaze on top, therefore it costs more, but it also looks very beautiful. When decorating a fireplace with majolica, you need to carefully consider the sketch, because cutting such a tile is not only impossible, but very stupid. In addition, the installation requires sufficient skill from the master, because the slightest flaws will be clearly visible. Due to the high cost and difficulties in our work, fireplaces very rarely finish with only majolica - they usually use it fragmentarily, as an accent and decoration. This solution looks gorgeous,

- brick tile It is made from special refractory grades of clay, therefore it is able to withstand high temperatures, and is also characterized by excellent frost resistance and moisture resistance. The color scheme is represented by shades of brown and terracotta, but thanks to various technologies for decorating the surface, you can get very interesting options,

- fireclay tiles it accumulates heat energy well, cools for a long time, keeps heat well. The material will expand with the fireplace body, can withstand extremely high temperatures. Fireclay tiles are thicker than terracotta.

This group is sometimes classified as porcelain tiles and tiles, but the uniqueness of their characteristics makes us consider each of these materials separately.

Tiling the fireplace has a mass the benefits:

- resistance to high temperatures, the ability to "breathe" with the fireplace,

- high heat transfer and the ability to accumulate heat, which increases heat transfer,

- moisture resistance, frost resistance, resistance to sunlight,

- ease of care

- durability,

- environmental friendliness, lack of smells when heated,

- chic appearance and ample selection.

It’s hard to name the minuses - unless the price of some products can scare off. For the installation of tiles, they take not ordinary tile glue - it is necessary heat resistant composition. You can make a special clay composition yourself, but you will need to find the right clay and experiment with the proportions, so it’s easier to stay on the finished version.

It is better to buy tiles with a margin of 10-15%, and you can buy not only products of a standard format, but also corner elements. Mounting does not require special skills and the use of specific tools:

- preparatory work consist of removing the old cladding from the fireplace. After this, it is also advisable to embroider the masonry seams 1 cm deep. The dust is thoroughly eliminated, the brick is wetted with water. Using heat-resistant mastic or clay mortar, eliminate small irregularities. In the presence of significant deformations, it is better to use a grinding wheel. If the brick began to crumble, then it does not interfere with installing a reinforcing metal mesh with a mesh size of 1.5 cm,

- Before starting work, it is necessary to melt the fireplace for several hours so that the brick warms up sufficiently. The tile itself should be in the room where the work will take place for 48 hours,

- the surface of the fireplace is primed, reducing dust and improving adhesion. The primer should be allowed to dry for about 2 hours,

- the tile can first be laid out on the floor to understand which elements will have to be trimmed,

- glue is prepared according to the instructions indicated on the package. Mixing is best done with a construction mixer, but a drill with the appropriate nozzle will do,

- masonry begins with special corner elements, if used. Then the lower rows are mounted,

- the adhesive solution is applied with a flat spatula, and immediately for installation of 3-4 elements. To ensure that the distance between the tiles is the same, use special crosses,

- after mounting the tiles overwrite the seams. To do this, use special store solutions or a clay mixture with sand and dyes prepared by hand,

- when everything dries, it is desirable to cover the surface of unglazed tiles with a layer of heat-resistant varnish. This will simplify subsequent care.

Analyzing the many advantages of the material and the simplicity of its installation, it is easy to guess why it has gained such high popularity.

No. 2. Natural and artificial stone for fireplace mantel

The stone in the decoration of the fireplace looks as organically as possible and may even resemble the Middle Ages, but the perception of the portal will largely depend on which breed of stone is selected (or which breed imitates an artificial stone).

Concerning natural stonethen for the fireplace use such breeds:

- granite - hard rock, has a wide range of shades, does not collect scratches, easy to care for. The surface can be both wild (with “torn” edges) and smooth polished,

- marble - the most popular stone for decorating a fireplace. It has a huge assortment of shades, it is relatively inexpensive, it looks great,

- shell rock captivates with low price and easy handling. It looks great, but not very durable. It has a soft porous structure, so gradually soot particles will collect in the pores, spoiling the appearance. If you rarely melt the fireplace, then the shell rock will do,

- limestone and sandstone differ in a sufficient number of shades, but cannot boast of durability, and soot can remain in the pores of the material,

- slate - durable and beautiful material, but its peculiar appearance does not allow us to call the breed universal.

Natural stone has a high weight and a fairly high price, so today an artificial analogue is actively used. Natural stone for fireplaces for sale in the form of plates. Often this format is called stone tiles or flagstone. Since the shape of such tiles is usually different, it is better to first lay out all the elements on the floor so that it is possible to pick up and process all the elements in time. When installing natural stone, you can’t do without a mesh, otherwise the finish risks falling apart.

Fake diamond made on the basis of Portland cement with the addition of expanded clay or on the basis of gypsum. The mass is poured into the forms that they receive by making casts from natural stones. Such products cost less, weigh less, can have any color and shape, in terms of strength and other operational qualities they are practically not inferior to natural stone, and even surpasses some breeds.

The main advantages stone fireplace lining:

- resistance to high temperatures,

- environmental friendliness and safety,

- chic appearance

- durability,

- for artificial stone, ease of installation and processing, low weight, price,

- for natural stone - the uniqueness of each element.

Stone laying technology resembles the tile installation described above. Between the stones it is not necessary to leave gaps of the same size (as is the case with tiles), so that everything will be even simpler. For installation, they take a special heat-resistant adhesive for stone. The heaviest stones are recommended to be additionally fixed with anchors. Otherwise, everything is the same as with tiles. First, the surface is prepared, primed, glue is diluted, then the installation of stone begins from the bottom row. Before starting work, it is recommended to melt the fireplace, and place the stone on the floor in order to assemble the future "drawing". In the case of natural stone, the elements may have a slightly different shade. This must be considered in advance. Looks best when the bottom rows are slightly darker than the top. If desired, the stone is coated with heat-resistant varnish.

Number 3. Brick fireplace

This is not even a finish in the traditional sense of the word. In this case, there is no question of installing some kind of facing material on top of the fireplace. The brick from which the fireplace is built is accordingly finished. This is both simplicity and complexity of the method.

If you originally planned not to use any additional facing materials, then when laying the fireplace, the mortar must be laid so that 5-7 mm remain to the outer edge of the brick. Later this void will be filled with decorative grout. If the fireplace is already built, then it is possible to complete the jointing for the subsequent use of a grout of a certain color. You can not touch the brick, but you can polish or chamfer. Such work should be performed by an experienced specialist. Not every stove-maker is ready to do this, so it is better not to perform such a facing on your own. Brick can be treated with hydrochloric acid solution - so the material will acquire a more saturated color.

There is a more standard way. This is the finish facing ceramic brick plastic molding. The material normally withstands high temperatures, looks great and expands the possibilities of decor. Masonry is not much different from masonry of ordinary brick. True, you will have to monitor the evenness of the seams (as is the case with tiles), and then seal them with heat-resistant mastic.

Number 4. Porcelain stoneware cladding

Porcelain tile is not a natural material, but it contains natural components. A special technology allows you to create material that It is not inferior in strength to natural stone. The composition includes clay, mica, sand, metal oxides, feldspar and granite or marble chips. Porcelain tile can repeat the pattern of any natural stone, different minimum pores, which explains its performance.

Material Advantages:

- wear resistance and high strength,

- ability to withstand high temperatures, so porcelain stoneware is definitely suitable for facing a fireplace,

- moisture resistance and frost resistance,

- environmental friendliness

- ease of maintenance, resistance to mechanical damage and chemically aggressive substances,

- a huge variety of colors and textures. Porcelain tile can copy ceramic tiles, any kind of stone, majolica and clinker.

It costs porcelain tiles a little more expensive than terracotta tiles and can make it a decent competition. Of the main cons: higher weight and relative complexity in processing - cutting porcelain tiles is not as easy as tile. However, for facing the fireplaces use plates of material with a small thickness, so that there will be no significant load on the floors. If at home it is difficult to perform cutting, you can entrust this task to special firms.

Installation of porcelain tile carried out on glue or on a metal frame. The first method is actually identical to the tile installation described above, so it makes sense to dwell in more detail on the second option:

- a frame is created from the metal profile around the perimeter of the fireplace; anchor bolts are used for fastening. Profiles are connected with self-tapping screws.The step between the profile should correspond to the format of porcelain tiles,

- with the help of special brackets, the porcelain tile is fixed on the frame,

- the space between the brickwork of the fireplace and porcelain stoneware must be filled with clay mortar with the addition of sand and gravel,

- joints of porcelain tiles are treated with a composition of clay, sand and color pigment,

- after the work is completed, the fireplace needs to be heated for a couple of days - this way the clay is sintered and forms a denser layer with a high degree of heat capacity.

This method is convenient for revealing fireplaces with a lot of bumps, defects and slopes, because with the help of a metal frame and mortar they are all leveled.

No. 5. Cladding for fireplace

Most simple and budget way to finish a fireplace is to cover it with a layer of plaster. Moreover, with plaster you can to form both a smooth and decorative relief surface (using different spatulas, brushes, rollers and even household items, such as plastic bags, you can achieve an incredible result). With proper dexterity, even the texture of the stone can be conveyed. Stucco can be painteddo drawings on it. The appearance of a plastered fireplace is very easy to change by simply repainting it. Plaster weighs a littleso that there is no significant load on the floor. Finish comes out durable and practical, if, of course, choose the right composition.

For plastering fireplaces it is better to take the same composition that is used when working with stoves. The easiest way is to buy finished material, in which the manufacturer added the necessary additives and additives. For those who know how and love to do everything with their own hands, there is a more complicated way - self-preparation of a stucco mortar. It consists of clay, sand and lime, but in order for the solution to have the necessary operational qualities, it is important to choose the clay fat and the proportion of clay and sand correctly - all this is done through experiments. To be sure that such plaster does not crack and withstand heat, experience will be required.

Many manufacturers offer both basic and finish plaster. The first is applied with a layer of 10 mm, intended for rough finishing and preparation of a flat base. The final layer is applied with a thickness of 3 mm.

The process of plastering a fireplace not much different from wall plaster:

- all old cladding, if any, is removed,

- to increase adhesion, it is better to expand the masonry joints to a depth of 0.7-1 cm. A chisel or screwdriver is suitable for scraping the mortar,

- it is better to seal the cracks with heat-resistant sealant,

- if the walls of the fireplace are relatively even (height differences and the depth of the depressions does not exceed 5 mm), then you can moisten the brick and proceed to the application of plaster. With more significant irregularities, reinforcement with a reinforcing mesh will be required. It is fastened to the masonry brick with nails, on the caps of which they wear metal washers,

- Before starting work, it is better to melt the fireplace so that the brick acquires the dimensions that will be characteristic of the operation of the fireplace. If the base is not warm, then the plaster may crack at the very first firebox,

- ready-mixed plaster mortar is applied with a spatula and leveled with beacons. It is recommended to apply at least two layers of plaster, and each subsequent is applied after the previous one has finally dried up. The finish layer can be leveled with a spatula. On it you can create a specific relief.

For additional decor, you can use paints. Organosilicon, which tolerate heating to high temperatures, are best suited. The hearth can be painted in the same color or you can draw certain patterns on it - it all depends on the imagination, skills and interior.

No. 6. Tiling

Tiles are, in fact, the same terracotta tiles or majolica. The difference lies in the special structure. The tiles have a rump, a square hollow ledge with which the tile is fixed during installation. Rump is important for another purpose - it helps to retain heat. Tiles can only be trimmed during masonry. If a moment is missed, you will have to choose a different finishing method.

For tiles, the same advantages are characteristic as for tiles. The choice of colors is huge, there are very exquisite designs that will bring a special chic to the interior.

Tiles are mounted in this way.:

- ½ rump is filled with a mixture of clay and broken brick, so-called soils are inserted into special holes crutch, thick (5 mm in diameter) wire with a bend at the top,

- In the middle of the crutch, a flexible soft wire is attached, which will later be embedded in brickwork,

- rumpa is filled with clay mixture to the brim,

- as masonry, tiles are mounted, the wire is hidden in the seam. Between themselves, individual parts are connected by U-shaped brackets.

Do-it-yourself installation is difficult to complete, which makes arranging a fireplace a more expensive pleasure. In addition, the material itself is more expensive than ordinary tiles.

Number 7. Wood fireplace mantel

Probably, many may find this way of facing impossible, because it is no secret that the tree is very afraid of fire. Nevertheless, when certain rules are followed you can decorate the hearth with warm and cozy wood - such a fireplace will look great in the living rooms, made in the classical style. Wood is an aesthetic, durable and natural material that has a special aroma. To enjoy these benefits, you have to observe a number of conditions:

- you must choose rocks that are resistant to high temperatures and not very susceptible to deformation at constant temperature changes. It is clear that all species of wood burn without exception, but those that have a denser structure ignite much later. Suitable for decorating the fireplace oak, hornbeam, maple, cherry. Larch has average density, and pine, cedar and linden should not be considered at all,

- is necessary impregnationspecial means that will prevent fire. These are flame retardants, which penetrate well into the structure of a tree,

- the tree is better to arrange as far from the hearth. Therefore, consider partial wood finishes or create a niche for installing cladding 5-10 cm more than a brick frame. Then the tree will heat up within acceptable limits,

- it’s better to cover the firebox anyway protective screenso that sparks do not fall on the wood.

Number 8. Drywall for fireplace mantel

Drywall is often used in the decoration of electric fireplaces. Material allows create any shape for the hearth. Actually, thanks to this feature, drywall has become so widespread. The main advantages of the method include low cost, simplicitymounting (only the lazy today do not know how to work with drywall) and, of course, a wide scope for imagination. We take into cons the need for additional decorative finishes and complexity in terms of ensuring the safety of the structure.

The principle of work is as follows:

- creating a frame from a metal profile. At this stage, you can create almost any form,

- inside the frame is upholstered with sheets of magnesite (glass magnesium sheet), which withstands temperatures up to 1200 0 C, can resist open fire for 2 hours, is characterized by high strength and sufficient flexibility. It is waterproof, easy to install, has good thermal insulation properties,

- basalt wool slabs are placed in the metal frame, which will protect the drywall from overheating,

- for facing take gypsum plasterboard refractory sheets, which perfectly withstand constant heating to 130 0 C and above, can resist open fire for 45 minutes. In addition, the crystallized water located in the core acts as a fireman for himself,

- when mounting sheets and insulation, holes should be provided along the edges of the fireplace, which will serve for better air circulation,

- joints of gypsum plasterboards should only be on frame elements,

- when the cladding is finished, you can proceed with facing with plaster, tile or artificial stone.

Remember that you can always combine several materials.

When it comes to a false fireplace, from which if heat comes out, it is only insignificant, you can use any materials you like.

We use plaster

If your old fireplace doesn’t look very good already, and you don’t have much money in your pocket, you can breathe new life into it using only plaster. If your fireplace is decorative - you can use the starting putty Rotband, Knauf, Fugenfuller. If you have a working fireplace on wood - to finish it you need to use a special solution of fireclay plaster.

First imagine what it will look like. In this case, there are a lot of options, you can create any structure from good plaster:

- under the tree,

- under the stone

- brickwork,

- vintage english style.

Apply the first coat of plaster and wait until the mortar has completely dried.

The second layer already needs to create the selected texture. Don’t be afraid to screw up, sometimes bizarre shapes look very beautiful in the end, you wouldn’t be able to do it even if you wanted to.

Next, you should paint the resulting structure in natural colors, it is recommended to use natural paints. You can even paint in two or three layers to achieve an uneven effect, in the end you should get something like this:

Special plaster fireplace

Fireplace decoration - best photos

Photo 1: Decorating a corner fireplace

Fireplace decoration in the photo hall

Photo - decoration of a decorative fireplace

Fireplace Design Photo

Fireplace decoration in a modern style photo

Photo of stone fireplace decoration

Living room with fireplace photo

Living room interior with fireplace - photo

Beautiful stone fireplace in the living room - photo

Do you like the article?

Save so as not to lose!