The activity of the whole water floor system is based on the mixing unit, which is responsible for adjusting the coolant system. This is due to the fact that with heating equipment moisture is supplied with a rather significant level of heating (up to 90 degrees), and in the floor surface this coefficient should be small (no more than 40 degrees). The thermal head, which is located on the damper, is responsible for maintaining the normal temperature of the coolant.

In the mixer, mixing of the liquid takes place, which proceeds with a significant temperature. As a result, it makes it possible to send to water circuits with the required temperature.

Three way hydraulic valve

This hydraulic valve has three passes. Of these, two serve for the flow of water flows, the third conducts the boiler into the design of the water circuit. To prevent metal corrosion, the block case is made of stainless metal. During operation heat the floor responds well to the environment, changing the position of the axle boxes and controlling the degree of heating of the liquid at the outlet. The thermal head is equipped with a meter that transmits signals to the actuator (close or open the valve).

It must be in a horizontal position.

Features of the three-way valve:

- It’s easy to install,

- mechanical and automatic adjustment is possible in it,

- it is durable

- it has an average price

- chemical and hydroprotection is present in it.

Two way hydraulic valve

The two-way version is a supply valve. A special thermostatic head is placed on it, which keeps control of the temperature of the coolant. As a result, the thermal head of the water floor closes and opens the hydraulic valve, adjusting the degree of supply of the thermal carrier from the boiler.

Features of this valve:

- safety and stability of floor temperature,

- constant stirring with cool liquid

- lack of third-party recharge.

Return temperature limiter

The Unibox Rtl Oventrop regulator, which limits the degree of heating of the return flow, is used on a small area of underfloor heating 2. The standard temperature range is 20-50 ° C and depends on the value set by the thermal head, due to which the degree of allowable heating is automatically maintained.

Floor heating controller Unibox Rtl Oventrop

Such a scheme involves installing the Unibox Rtl Oventrop so that the heat carrier circulates the entire floor heating circuit during circulation and only then through the Rtl controller.

The principle of its operation differs from the functioning of the mixing unit, where, in order to achieve the required temperature, mixing of liquid flows with a different degree of heating, controlled by a valve, takes place.

When using the Rtl controller, when water enters the hinges of the warm floor, mixing does not occur, that is, when connected to radiator heating, the coolant immediately moves into the heating pipe. The task of the RTL valve integrated in the regulator is to set the normally established limitation of the temperature of the liquid flow already at the outlet of the pipes of the water circuit.

Such a binding involves the supply of hot coolant in batches, so that overheating does not occur. The inertial screed also helps to smooth the temperature.

Rtl Valve Dimensions

When equipping a water heating system with an Rtl valve, it should be taken into account that the temperature set on the backflow restrictor must not be lower than the room air.

If this requirement is not observed, then unstable incorrect functioning of the Rtl controller may occur.

Structurally, it consists of a housing, a limiter for the limit stroke of the rod, as well as a liquid sensor, due to which the data on the temperature of the passing stream are transmitted to maintain the set heating value in automatic mode.

Water floor heating control scheme

The Rtl valve opens only if the maximum value has not been reached. A similar regulator is also used when equipping a combined combined warm water circuit, when the coolant flows in parallel to radiators and to the system.

A variety of options for connecting a water heating circuit allows you to rationally decide which circuit will be suitable for specific conditions. In country houses, when installing a local boiler with a controlled temperature of the outgoing water stream, it is possible to directly connect without additional nodes designed to reduce the degree of heating of the coolant.

Reasons to choose

Three main conditions for choosing the type of control valves should be considered:

Three main conditions for choosing the type of control valves should be considered:

- The area of the room. The greater the cubic capacity of the room requiring heating, the more difficult and more often it is necessary to carry out adjustment, therefore, automation must be set here.

- Pipe section. The valve passage must be at least Ø pipe. If it is larger, then put an adapter on a smaller pipe.

- Maximum flow (throughput). The characteristic is set when designing a warm floor.

If the floor heating is carried out in small rooms up to 10 m² and is not the main heating system in the house, then it is possible to supply the heat carrier to the circuit through 2-way taps. Such a device will automatically supply the necessary portions of hot water to the connected loop, maintaining the desired temperature.

Carbon floor heating device

Using a programmable underfloor heating controller

Electric floor heating technology

Connection of a heat-insulated floor without a temperature regulator

The device of the heated floor in the bathroom from heating

Installing a mixer for a warm water floor

Water floor heating is a high-inertia system, the control of which has a delayed result.

Water floor heating is a high-inertia system, the control of which has a delayed result.

That is, the reaction to any corrective action will not be physically felt immediately, which requires a more accurate and soft adjustment.

Otherwise, you can get too pronounced a change in operating mode - from a complete stop to the maximum heating of the surface.

All control of the system is concentrated in the mixing unit. mixing the colder streams into the original hot one. The main device that performs this action as part of the assembly is a mixing valve. Let's consider its functioning more closely.

Temperature mode

Before proceeding with the adjustment of the warm floor, it is extremely important to establish a clear idea of the purpose for which it is carried out. According to the principle of action, a water heated floor is radically different from other heating appliances

The main difference is the operating temperature of the coolant.

If the supply to the radiator network is carried out at temperatures up to 80 ° C, then the heating medium entering the underfloor heating coil is limited to 40–42 ° C. This need is due to comfort and safety. In normal mode, the temperature on the floor surface fluctuates in the range of 22–26 ° C; stronger heating causes unpleasant sensations.

There are two ways to control the heating temperature of a liquid floor heating. The first of these involves temperature control on the supply branch of the collector by mixing in a portion of the cooled coolant from the return. Technically, this solution is implemented by installing a three-way valve with a pressure-controlled RTL thermostatic head. The difference between such a head and a radiator is that it relies in work on the temperature of the coolant, and not air. With this method of regulation, the flow rate in the loops remains constant, with a small amplitude only the temperature of the coolant changes.

The second method of adjustment involves limiting the flow of hot coolant in the circuit. In this case, a thermostatic head is also installed, but it is located on a two-way valve that interrupts the return flow circuit. With this control method, the supply and return are connected by a bypass circuit, the flow through which is regulated by a restriction valve with a pre-calibrated throughput.

The principle of such regulation is based on the high inertia of the underfloor heating system. In the process, the coolant is fed into the loop at the nominal temperature of the thermal unit, only the total flow rate changes periodically. Thus, the screed is heated cyclically, that is, a significant heat capacity of the storage layer is required to smooth out temperature differences.

In both cases, there is one important rule: thermostatic valves must rely on the return temperature of the loop or collector. The device can have a mechanical or electronic principle of operation, it can even be a regular thermometer

The need for the correct location is due to the fact that it is almost impossible to judge the efficiency of adjustment by the value of the coolant temperature at the flow, because the length of the loops can vary significantly.

Servos for underfloor heating systems

There is no way how to adjust heated floors in automatic mode without a servo drive (another name is a servo motor). This is an electrothermal device, the main purpose of which is to open and close the supply of hot coolant.

The main element of the servo drive is an elastic bellows, which has the form of a sealed cylinder. It is filled with a substance that can change volume depending on temperature.

Around the bellows there is an electric heating element, to which power is supplied after a signal is received from the thermostat. When he joined the work, the substance in the cylinder begins to heat up and expand. The bellows, which has increased in size, exerts pressure on the stem located below, which shuts off the flow of coolant. Since the work of these devices uses only thermal energy and electricity, they are usually called thermoelectric.

Servo drives are normally closed and normally open. Their name indicates the position of the valve during a power outage. In the first case, the valve is in the normal position open, and closes after receiving the signal. In the second case, everything happens the other way around, first it closes, and then it opens.

Adjustment of heating of water floors

Most often, to equip water heating of the floor, they use the connection of heating circuits by means of a collector to which both ends of the pipeline go: one of them delivers the coolant, and the second returns it back. At the entrance to each of the heating circuits, hot water arrives at the same temperature.

Since the length of the pipelines is different, each of the rooms warms up to a different temperature. For example, for a bathroom, this parameter should be 25 degrees, and for living rooms it cannot exceed 22 degrees. To add or reduce the degree of heating the room, you need to change the amount of heat carrier supplied to the circuit.

The easiest way to regulate the temperature of a water heated floor is to equip the collector with special inlet and outlet valves (for more details: “The scheme of the collector of a warm floor - how everything should work”). By turning their heads, the amount of heat carrier supplied to each circuit can be adjusted. In this case, you have to focus only on your own feelings, and this method of adjusting the heating can not be called convenient.

The sequence of actions is as follows:

- adjusting valves tighten

- wait for some time until the floor warms up,

- evaluate the result

- again tighten the valves, etc.

Since the temperature on the street is almost never the same for even one day, the owners of the house have to rotate the valves very often, and manually.

The thermostats shown in the photo are usually placed in each room where the floor heating with water heating is mounted. In turn, each circuit on the heat carrier comb is equipped with servos. According to the signals, they increase or decrease the amount of water supplied to the circuit. Thermostats are connected to specific servos and send control commands to them.

The regulators control either the temperature of the warm water floor or the air mass in the room. At the same time, it is necessary to monitor the temperature of the air in the room when heating the floor surface is the only way of heating in the house.

The principle of operation of the floor heating controller:

- The necessary temperature is set on the equipment case (floor surface or air, depending on the specific model).

- If the parameter deviates in one direction or another, a signal arrives at the servomotors, after which the supply of the heat carrier either increases or decreases. As a result, after a certain time period, the temperature returns to normal.

When the pipes are filled with a screed, it takes time for the entire concrete mass to heat up or cool down. If there is a floor heating system, the inertia is less and then the changes come faster.

What are the criteria for choosing a thermal head?

Thermostatic devices are produced by many manufacturers.

To make the right choice, you must be guided by the following criteria:

Thermal valve to which the head will be attached

Since the connection can be clip or threaded, you need to pay attention to this point. If the manufacturer is the same, there will be no problems.

Type of threaded connection on the head itself

It can be in the form of a nut with blinds or just round. In the first case, during installation, an additional tool is needed to crimp the connection. In the second - everything is much simpler.

The presence of a "skirt". With her head looks better, because it closes the work area.

The material of manufacture. The cheapest are thermal heads in a plastic case. For expensive models, the case is metal.

The quality of the plastic. Some manufacturers, in order to reduce the cost of their products, use the cheapest type of plastic. The structural strength suffers from this, and over time, the plastic turns yellow and loses its aesthetic appearance.

Type of work item. The choice will have to be made between liquid, gas, electronic and paraffin.

Smooth rotation. The handle should rotate smoothly. This is a sign of good quality. All sorts of crackles, creaks and seizures indicate a poor quality product.

Graduation and scale length. For most models, it is in the range +5 - +30 ° C. If the scale is located around the entire perimeter of the head, it can quickly be erased.

The presence of an anti-vandal casing. It protects against unauthorized access to settings.

Design. Since the thermal heads are mainly located in plain sight, their appearance and color scheme are important.

A complete set consisting of a thermal valve and a thermal head is optional. These devices can be purchased separately.

Gas-filled bellows are not too sensitive to external heat sources. This is a definite plus, but its cost is much higher than that of a liquid bellows

Gas-filled bellows are not too sensitive to external heat sources. This is a definite plus, but its cost is much higher than that of a liquid bellows

A thermal head equipped with automation wins a lot, but it is not always effective. It makes no sense to mount it on cast-iron radiators. This material is very heat-absorbing, and since the mass of the battery is large, it has great inertness. Only the manual type of head can work correctly here.

System fueling rules

It is impossible to properly configure the functioning of the water structure if the volume of liquid in the pipeline will change independently. This can happen if there is air in the system.

Therefore, it is important both to professionally mount the structure and to properly fill it

For a high-quality filling of the system, both collector branches should be equipped with automatic air vents. Filling of floor hinges should be carried out separately from other heating devices. The generator and radiators are filled in advance. Before refueling, the collector inlet valves are closed.

To properly start the floor, you need to connect a hose to the supply tap from the water supply or pump, and to the return pipe to the air outlet.

It is necessary to start filling the water floor with the collector and its distribution nodes. To do this, the flow meters of the supply valve open to full, at this moment the valves on the return should be turned off.

The loops are filled in turn, while the water is let in from the bleed hose, it will not go clean, and without air bubbles. Run water should be a small pressure, this will make the process of air exit from the pipes more uniform. After filling all the loops, the device can be turned on.

Work with collector flow meters

Under the balancing of underfloor heating means the definition of norms for each loop. Indeed, from the size of the floor branch, so that in the process of passing through it the coolant cools down according to the calculated value, the amount of water required is different. The volume of fluid that the loop passes through is the heat load on it.

Not rarely, it is recommended to determine the flow rate of the coolant, starting from the pump power, that is, the volume of the incoming fluid is divided proportionally to the length of the loops. However, it is worth abandoning this method, since it is not easy to accurately calculate the size of each coil with this method.

In addition, calculations by this method lead to a mismatch of the pressure in the loop with the calculated value, which makes it impossible to adjust the design.

The adjustment process itself with flowmeters is simple. The bandwidth of the device is configured according to the model, either by turning the body or rod using a key. The device displays the amount of water in liters that has passed in a minute, you only need to set the desired value.

Basically, always, when adjusting the bandwidth of one loop, a change occurs in others. Therefore, the process should be repeated sequentially with each flow meter. Significant malfunctions indicate that the valve has poor throughput, or that the circulating pump has a low capacity.

Variety of floor water regulators

The fundamental difference between different control devices is the way to set the required temperature:

- Mechanical modifications. These appliances rarely break and are affordable. This type of water underfloor heating controller has a simple scale making the setup process easy and straightforward. The required temperature is set using a rotating disk. Sometimes on the front panel of thermostats for water floor heating there is a lever designed to turn it on / off. There are no other functions for such devices. The average price for them is 15 euros.

- Electronic devices. Their functionality is similar to the mechanical version, but it is implemented differently. The electronic model provides for the presence of a digital screen on which the current or set parameters are displayed. Also on the devices you can see several buttons. They may contain arrows with up and down signs, which serve to gradually change the temperature regime. Estimated cost - 20 euros.

- Models with programming. Adjusting the temperature of the warm floor using such a device allows you to maintain stable heating, and change it in automatic mode, depending on time. Models are sold that have the ability to program the temperature during the day and on the days of the week. This function allows you to save energy resources, which means money and still live in comfortable conditions. For example, the temperature can be lowered when all family members are away from home, and raised before returning. Some modifications, in addition to the stationary unit located on the wall, are equipped with portable control panels. Now on sale there are models that adjust the work through a computer or tablet. The simplest modification, which provides for the ability to set the floor temperature in time, will cost no less than 40 euros, and a fancy device can cost more than one thousand.

- Multizone modifications. Such thermostats control several circuits and maintain individual parameters in each of them.

- Touch models. The list of functions performed by these devices is the same as that of electronic models. But they are equipped with touch buttons, not tactile ones. The cost is higher.

- Radio thermostats and controllers. Similar systems supplied by European manufacturers are new in the domestic market. For example, Uponor systems consist of servo-mechanisms controlled by radio signals, a radio thermostat that monitors sensors and a radio controller that receives data from the thermostat and passes them on to the servos. The kit also includes an SMS module that allows you to control the system through mobile communications and monitor its status.

Heating valve

The thermal head is installed strictly horizontally and includes a specific meter that transmits to the electric drive signals about closing or opening the valve. The hydraulic valve has three strokes for the coolant, two of which are used to supply water to the mixer, and the third is responsible for supplying the total flow to the pipeline.

The unit is made of stainless steel, since the device has to work in a constantly humid environment and there is a risk of corrosion. In the operating mode, the floors are sensitive to changes in heat in the room, automatically adjusting the heating of the circulating fluid inside.

Selection tips

It is best to purchase a ready-made kit, which already includes all the cranes and other necessary components. For different sizes of space there are laying systems, so the method of installing equipment for a small apartment is not suitable for a large house.

When installed correctly, such a floor should not be visible under the parquet. It is worth considering that the more programming functions of the warm floor, the more expensive it will be. For example, for different rooms, you can choose, respectively, different temperatures.

When choosing one or another heating scheme, it is always necessary to take into account the volume of the heated room.

In order to save money under the cabinets, sofas and other types of furniture, the space is not insulated.

It is necessary to carefully choose the material of the heat insulator, on which the durability of the system largely depends - foam and foam are the most common options.

Adjustment mechanism

Thermostatic mixing valve

A thermostatic mixing valve is also used in radiator-type heating circuits, but convective air circulation (even with balanced ventilation and thorough warming) still leaves the lower layers as the coldest part of the room.

The heat source can be either a heating plant or an autonomous boiler. In any case, the boilers work effectively in stable conditions and will not provide a smooth adjustment of the flow of coolant in each individual room.

For this purpose, special fittings with selected operating parameters and a certain type of construction are included in the system. Installing a mixing valve for a warm floor gives the following stabilizing result for normalizing the temperature in the house:

The mixing valves perform the task of combining the high-temperature heating circuit with the low-temperature wiring of the warm floor, since the recommended temperature in the pipes under the floor is 40 ° C, and for the water leaving the boiler 70 - 90 ° C.

Work principles

If the coolant is too hot, a cold stream is mixed into the water

The three-way valve for underfloor heating performs its function in the following order:

- hot heat carrier from the boiler is sent to the distribution manifold, from which it diverges along the hinges of the warm floor system,

- a heat mixing valve is installed in the path of movement, which responds to the temperature of heating the water,

- when the flow temperature exceeds a predetermined value on the regulator, the passage opens for the latter to mix chilled water from the return pipe,

- in the tee, two converging flows are mixed and the desired temperature is delivered to the coolant system,

- when the balance is reached, the change in the internal cross sections of the valve stops.

The valve body is made of brass, represents 3 channels, converging to the adjustment mechanism. Using 3 different methods of mixing water flows distinguishes 3 types of three-way valve designs.

3-way thermostat

Thermostat mixes hot and cold flow

The set temperature is maintained by a three-way thermostatic valve, which automatically mixes the hot fluid flow from the heater and the cooled water from the return pipe. The need for a quantitative change in flows is determined by the thermostat settings.

Such a product can be used in underfloor heating systems (especially complex configurations), on radiator wiring and in the internal circuit of hot water supply.

An automatic change in the temperature of the outgoing coolant protects a person from elevated temperatures when a pipe ruptures. If for some reason the flow of cold water stops, the valve will automatically close the duct to the hot pressure from the boiler. The temperature-sensitive unit responds to the amount of heating and, accordingly, changes the cross section of the inlet openings, reaching the desired balance.

The layout of the thermostatic valve for a warm floor looks like this:

A pressure restrictor is a device that provides a pressure head for a fluid regardless of the pressure drop at the inlet and outlet. Paired with a thermal head for a warm floor, it stabilizes the operation of all system circuits when changing incoming conditions.

3-way thermostatic valve

The operation of this valve is not as complicated as a thermostat. Only incoming hot media is regulated. For more information on the operation of three-way valves, see this video:

For analysis of changes in temperature indicators, the set includes a thermal head for a warm floor, which acts as an executive body by a signal from an external sensor.

Mixing valve

Manual valve manually adjustable

A three-way mixing valve, not equipped with sensors and automation, is even simpler. The manual valve needs to be forced to set the position of the regulator to obtain a given outlet temperature.

Such a crane is made of 2 types:

- has a T-shaped passage (symmetrical pattern),

- internal L-shaped passage, (asymmetric).

The differences are that in a symmetrical design 2 jets meet from the opposite shoulders of the crane and go into the side branch already in a mixed state.

In the asymmetric version, cold water rises from below, the hot stream approaches from the side, the mixed medium leaves in the direction of movement of the hot.

Device and principle of operation

The convenience of staying in the premises largely depends on the heating system used. Control over the temperature of a water heated floor is carried out using special devices - temperature regulators.

Many designs of such systems are used, but in most cases they use only a few fundamentally different methods of adjustment.

Watch video - setup process

But, before considering the principle of operation and the arrangement of temperature regulators, you need to understand the object of regulation.

What is heating wiring?

Heating a room with a water floor can be carried out in various ways. One of them is the use of heat of heated water, which acts as a coolant. Transfer is made through pipes. Previously, steel pipes were mainly used in heating, now they are replaced by modern ones made of plastic materials.

The heating circuit can be located along the walls in the form of radiators, and can be located under the surface of the floor, heating it and the air in the room.

The heating circuit can be located along the walls in the form of radiators, and can be located under the surface of the floor, heating it and the air in the room.

Hot water or antifreeze is heated in the boiler, after which, using a circulation pump, it is fed into the heating circuit of the water floor.

Passing through its pipes, the coolant transfers heat to the enclosed space, heating the surface. The cooled liquid is returned to the boiler room system. Depending on the temperature of the "return" in the mixing unit, it is heated or cooled by mixing with colder water from the tank.

In circuits with underfloor heating, which are connected by a separate circuit, a temperature controller is installed for each of them, since they all have their own thermal regime. And the radiator heating circuits heat up to a temperature that is almost twice as high as for a warm floor.

How does the temperature control principle work?

The main elements of heating control are servos, temperature sensors and temperature controllers. This composition of the equipment allows you to adjust the temperature of the water floor heating steplessly in continuous automatic mode. It happens as follows:

The main elements of heating control are servos, temperature sensors and temperature controllers. This composition of the equipment allows you to adjust the temperature of the water floor heating steplessly in continuous automatic mode. It happens as follows:

- If an insufficient temperature signal arrives from the temperature sensor, the servo-driver opens the valve and more hot water enters the heating circuit.

- When the coolant overheats, the valve for mixing chilled water opens, reducing the degree of heating in the circuit.

- However, it is possible to adjust in manual mode by setting the crane in a certain position. But this method requires constant visual monitoring, since the factors on which the heating mode depends, change repeatedly during the day. With the relative cheapness of such devices, they are very inconvenient in operation, since each property in the room requires intervention in the heating operation.

Adjustment options

Watch the video - adjust the power of the temperature sensor unit

- The degree of heating of the floor covering. In this case, the heating sensor is installed in the immediate vicinity. Such a floor heating device is best suited for small rooms and low-power heating circuits, which are used only as auxiliary, in particular for a heated floor.

- Indoor temperature - with this control scheme, sensors are used that are mounted directly in the thermostat housing. The correct operation of such a device can only be achieved if all the requirements for warming a heated building are met. Otherwise, it is difficult to achieve effective heating operation - significant energy losses are inevitable. A properly built house with an extensive heating system and a temperature controller can provide up to 30% resource savings.

- Combined control system, in which the temperature sensors of the water floor heating are installed both in the heated room and on the mixing unit system. The parameters are adjusted for reasons of the most comfortable temperature in the house. Such equipment with a temperature controller is used in large rooms. Both sensors can be used for control simultaneously or one of them.

Conclusions and useful video on the topic

The device and purpose of the thermal head are described in detail in the following video:

Should I install a thermal head on batteries? This is described in detail by one of the users in his video review:

Thermostatic valve and head in action:

The heating circuit with a thermal head is more convenient to use. This device increases the life of the equipment included in the heating system, increases its fire safety.

Based on the benefits of these relatively simple devices and their 20-year life, their cost is low. To buy a product of really high quality, find out if there is a certificate for the selected device.

Do you use thermal heads for your heating equipment? If yes, then share your personal experience with installation and operation, add photos, tell us if you are satisfied with these devices and how much more comfortable the microclimate in your house has become after installing the thermal heads.

If you still have questions, then do not hesitate to ask them in the comment block - our experts and competent users will try to cover difficult moments as much as possible.

The role of the thermal head

Underfloor heating is a self-installed heating system that provides warm air to a living room. The device of uninterrupted operation implies serious requirements for the installation of equipment and for operation. For the responsibility of uninterrupted heating of a water floor heating, a thermal head is responsible. It is also a stable indicator of the temperature that needs to be controlled.

The principle of operation of the thermal head

Proper mixing of hot and cold water should ideally match the sensor.

There are standards that include the degree of heating inside the system to 90 degrees, while the floor itself should not be higher than 40 degrees. The optimum recommended temperature is 22 degrees. Proper operation of the thermal head is the key to the uninterrupted operation of the entire system.

Advantages and disadvantages

Such heating has a number of undeniable advantages, among which the cheapest operation comes first. A warm floor heats the whole room compared to mounted electric batteries, during operation of which heated air rises, and the floor, in fact, remains cold.

Such a heating device does not upset the balance of humidity in the room, which is also an indisputable advantage.

The warm floor does not have any critical flaws, but some nuances should still be taken into account. The complexity of installation makes serious demands on the preparation of the area. A serious inconvenience can be a leakage of the pipeline during operation, because in case of repair it will be necessary to open the floor covering. Such a floor cannot be installed in hard-to-reach places (on stairs or in small rooms), which requires additional heating equipment.

System features

For a stable heating of the floor temperature, a thermal head is installed, which is installed on the valve.

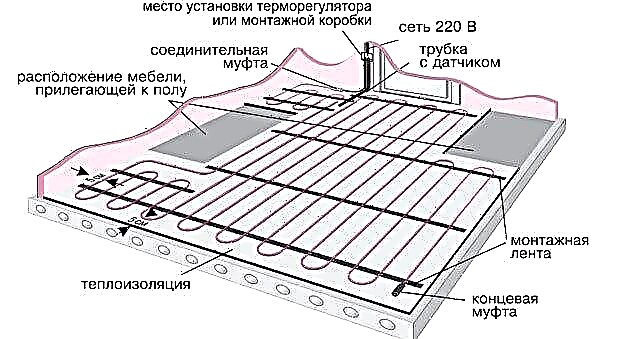

The usual system includes pipes, thermal insulation, a thermal head with a sensor, fasteners, a welt tape, accessories to minimize seams, manifolds with fittings and sometimes an additional package of the pump group. The functioning of the warm floor is carried out in the mixing unit. When it enters the heating system, the water mixes, thereby achieving a certain temperature level.

Mechanical temperature controller: principle of operation

If the air space in the room is heated to the required level, the working area in the bellows expands under the influence of heat, which causes the hydraulic cylinder to straighten. The stem, combined with the bellows, rushes forward, exerting pressure on the hydraulic valve, pressing it against the passage hole. In this case, the flow of coolant in the battery (heating) is stopped.

After the carrier remaining in the heating battery has cooled, the mixture (or gas) in the thermocouple is compressed, causing a decrease in its walls, which leads to the opening of the valve. Heated coolant enters the system, then the course of action begins again.

Features, functionality

The functioning of the entire construction of the water floor is based on the mixing unit, which plays an important role as a temperature controller for the heat carrier. This is due to the fact that water is supplied from the heating equipment with a sufficiently high degree of heating - up to 90 ° С, and on the floor surface this indicator should not be higher than 40 ° С.

Operation of the underfloor heating system

The thermal head, which is installed on the valve, is responsible for maintaining a stable temperature value of the coolant. In the mixer, the mixing of fluid streams going with high heat from the feed and cooled from the return or water supply, which allows you to send coolant with the desired temperature to the water circuits.

Three-way valve

According to the design solution, the three-way valve has three holes, two of which serve for the intake of mixed water flows, and the third diverts the coolant to the water circuit system. The strapping scheme provides for branching on the return, which allows the excess of cooled coolant to be sent to the water heating device.

The structure of a three-way thermostatic mixing valve

The three-way valve body is made of corrosion resistant materials, such as bronze. The main part of this device includes a thermal head, which is installed on the rod through a special axle box.

During the functioning of the warm floor, it reacts to the surrounding temperature, changing the location of the axle box and adjusting the degree of heating of the outlet water in accordance with the set values.

To read the temperature, the thermal head is equipped with a sensor that transmits signals to the actuator, which, depending on the values obtained, closes or opens the valve. It is mounted so that the thermal head occupies a horizontal position. With a pipeline length of more than 40 meters, a circulation pump is installed to drive water along the contours.

Two way valve

The layout of the easy-to-use warm floor with a three-way valve is attractive due to its versatility. But it should be borne in mind that for small heated rooms, you can use a cheaper two-way valve, the design of which also has a thermal head equipped with a sensor. This device delivers the cooled coolant constantly, and hot liquid flows as needed.

Two-way valve assembly diagram

After mixing, the liquid with the set temperature controlled by the sensor is supplied to the collector. On the return circuit, two check valves are additionally installed, which do not allow the flow to move in the return direction.

Types of thermal heads for adjusting the warm floor, their design and installation options

To ensure a comfortable temperature is constantly maintained in the heated room, thermal heads are included in the heating circuit. This element performs the function of continuously monitoring the temperature of the coolant in the system and regulates its flow.

The thermal head is part of a functional unit paired with a thermal valve. The thermal valve is controlled by a thermostat, which responds to changes in the temperature of the coolant or ambient temperature. In the wiring diagram, it can perform a cut-off or mixing function.

Thermal head

Thermal heads are indispensable for a warm floor, since when connected to heating boilers, the temperature of the water in the supply will be too high for the floor.

The device and principle of operation of the thermal head

Structurally, the thermal head is a thermodynamic mechanism in which the ability of substances to expand when heated is used. A container with a substance that reacts to heating is located in its body; a valve stem pusher is installed under the container. The principle of operation of the thermal head is as follows:

- In the thermostat housing is a container (bellows) filled with liquid or solid. The walls of the bellows are corrugated, so it is able to stretch.

- When heated, the substance inside the bellows expands, and it stretches, exerting pressure on the valve stem. The system is balanced by a spring.

- When cooling, the bellows returns to its previous state and stops pressing on the stem.

The scheme of the internal device

Thermal heads can be sold separately, but they usually come with a valve.

Important! It is better to purchase ready-made kits, since not all cranes and heads are suitable for the thread pitch and the footprint.

Depending on the type of valve, such kits may be called angled, direct thermal heads. Choosing the right type depends entirely on your system configuration.

By the type of substance filling the bellows, thermostatic heads are liquid, paraffin and gas.

Thermostatic head with external sensor

Liquid devices are inertial; they do not work as fast as gas devices, since they require more time for heating and cooling. But they are more accurate. Gas appliances operate with a high error amplitude, they are more sensitive to external temperature noise (drafts). Mnemonic circuits indicating temperature zones are often applied to thermostatic heads. The graduated scale for such devices is inefficient due to errors.

According to the control method, thermal heads are manual (mechanical) and electronic. Mechanical thermostatic heads are equipped with a rotary handle with a radial scale. The value of one scale division is 2-5 degrees (depending on the model). Management is carried out by turning the handle of the head and setting it to the desired division. This increases the distance between the parts of the pressure transmission mechanism from the bellows to the stem.

Electronic thermal head

In electronic devices, temperature parameters are controlled by a display, and the rod can be actuated by an electric drive. These devices are more expensive, but they allow you to set the temperature regime with high accuracy or program daily changes.

According to the method of contact of the thermostat with the surface of the pipe, the thermal heads are overhead with an immersion or air sensor. The contact thermostat heats up at the installation site. By design, the thermal heads with an external temperature sensor are exactly the same as the invoices described above, only the thermostat bellows are connected by a capillary tube to an external remote hermetically sealed can. It is filled with the same gas as the bellows. The expansion of the bellows occurs when heating a remotely removed spray can. In the system of underfloor heating, such devices are used.

Floor heating control

Thermal heads are an inexpensive and effective solution for controlling the temperature of the coolant in the floor loop. A heat carrier with a constant temperature of 70-90 degrees leaves the boiler. You can get a comfortable floor temperature with thermostatic heads in the following ways:

- To carry out periodic short-term supply of hot heat carrier to the floor contour. The coolant fills the circuit, and the flow is interrupted until it cools down to the set limit.

- Install a system in which the flow of coolant will be constant, but mixed with the supply of cooled water from the return.

The short-time supply system is mounted in rooms with a small area. Usually it is a bath or floor, ceramic coating. A two-way valve equipped with a thermal head and an external floor sensor is connected to the feed system. After filling the circuit, the floor warms up, the sensor is triggered, and the valve blocks the flow of coolant. After the screed cools down, the valve opens again and the system fills with hot water. Such a scheme is an economical alternative to the mixing unit when installing short heating systems. In this way, it is best to connect to the return of the radiator heating, since almost boiling water entering the floor loop is not welcome due to the risk of damage to the entire structure.

Experts have a lack of confidence in the method of portioning the circuit with hot water. The logic of the circuit is simple, but in practice, not everything is so smooth. The main argument is the uneven heating of the pipe. At the input, the temperature will be 80 0, and at the output where the sensor has triggered, it will be 30 0. It is clear that such a floor will not evenly heat up. Therefore, a special pipe-laying system is needed here so that the sections closer to the entrance are laid next to the pipes from the supply side. This is another confirmation that such a scheme is not suitable for large rooms.

RTL series thermal head valves that do not have a remote sensor are specifically designed for underfloor heating. They are installed on the return pipe and maintain a constant coolant temperature, regardless of the floor temperature. They have the ability to adjust the upper temperature threshold (usually not higher than 40 0). When installing such models, it is necessary to adhere to the general installation rules. The RTL head is preferably installed in a horizontal position. However, you cannot set the upper temperature threshold lower than the ambient temperature in the room. This system performs point "injection", due to which a certain constancy of the movement of the coolant is maintained, and there is no overheating of the circuit.

Connection diagram with three-way valve

In the second method, it is necessary to install a three-way valve with a thermal head and a floor sensor in the supply system. From the return pipe through the tee, a connection is made to the third outlet of the valve.

Important! In this case, it is necessary to correctly connect the valve so that the output to the supply always remains open.

The thermal head is installed on the valve through a special locking box. When the sensor heats up, the valve stem shifts, while inside the body a gap opens to mix cooled water from the return and the feed gap narrows. So the coolant of the set temperature will constantly enter the system. Due to the fact that the water flow will be continuous, the floor surface will warm up to a comfortable 28 degrees. In this case, you can not be afraid that pipes can become spoiled or the screed can crack from too high a temperature of the coolant. You can not do without such a scheme if the heated floor is connected to one mixer with a radiator circuit powered by the boiler.

In addition, the cold water mixing circuit is suitable for heating large rooms and will maintain a constant temperature.

Thermal heads allow you to install inexpensive and small systems of underfloor heating, while you can do without an expensive collector group.

Electronic thermostats

There is a slight numerical display and a series of keys. The display shows the current characteristics of the system, or set. The keys (often with the up and down arrows) are designed to change the temperature. Programmable temperature controllers make it possible to maintain a stable floor temperature, You can automatically change it on specific days of the week, or time of day.

There are modifications that, along with the stationary control unit on the wall, have a portable control panel. Certain models make it possible to manage the work through a personal computer or tablet, which is quite convenient. These devices can control the heating of the floor.

The water-insulated floor is the best heat resource, with its help convenience and comfort are introduced into the atmosphere of the home.

You can learn more about how to ensure accurate temperature control of the warm floor with your own hands.

Thermal valve function

Thermal head and thermal valve are an integral element of the radiator heating mechanism. When the system is connected, temperature readings come to the valve that can be adjusted. Today, two-way and three-way valves are common. The thermal head and thermal valve are the “heart” of the warm floor.

The principle of operation of the mixer with a two-way valve

A thermal head with a sensor for underfloor heating is connected to a system with a two-way valve. Hot water is supplied through it from the boiler to the mixing unit.

The sensor determines the temperature of the coolant supplied to the floor heating, and with its large value, the thermal head valve cuts off the flow from the boiler. The circulation will take place along the inner circuit until the water begins to cool. Upon reaching the set minimum value of the temperature of the coolant from the sensor receives a command to supply hot water and it again begins to mix with the return.

The small capacity of the two-way valves provides heating of rooms with an area of not more than 200 m 2.

Mounting

Installing a warm floor is troublesome and, as it might seem at first, costly. However, subsequently, the benefits and benefits are obvious. As practice has shown, during operation such a system is cheaper and more practical than other types, but at the same time, installation will cost more than for other systems. All costs will pay off, and as a result, the heating season will save up to 20%. It is better to entrust the installation of such a floor to qualified specialists, which can guarantee safety.

High-quality temperature control of underfloor heating

The method consists in mixing hot water coming from the boiler with a cooled coolant returning back to heating. For this, a three-way valve with a thermal head for a warm floor is used. As a result, water with a predetermined temperature is supplied for heating.

The thermal head is connected to the valve stem through the axle box, which locks the input to the point of its connection. At the temperature sensor signal, the stem with two poppet valves moves. In this case, the passage for one flow opens and closes for the other, as a result of which the temperature of the coolant supplied to the heating circuit changes.

Types of temperature sensors

The remote temperature sensor is a can of gas. It is connected to the bellows of the thermal head by a capillary tube. As the temperature rises, the pressure inside the canister increases and is transmitted through the bellows to move the rod, which covers the flow of hot water through the valve. When the air temperature decreases, the flow of coolant increases.

Instead of gas, a paraffin or liquid thermal valve can be used, which is more inertial. The signal is fed to a heating element located in a cylinder with heat-sensitive filler. When heated, paraffin melts and increases in volume. He presses on the piston and he moves the stem with a valve disc. The range of temperature control of the coolant is in the range of 20-40 0 C.

The temperature control of the heating medium occurs in the mixing unit, consisting of a valve, thermal head and pump. Regulation is performed continuously, and mixing of flows is carried out inside the valve.

Management can be done manually by turning the cover of the thermal head with a scale. In position "1" flows are supplied in equal quantities. The adjustment is coarse because the heat consumption for heating is variable. A more precise control is made by a thermal head with an external sensor for a warm floor inside the return manifold. The method is one of the most effective, although expensive in terms of the equipment used.

Quantitative temperature control of underfloor heating

The distribution comb or manifold is a unit that ensures the correct operation of the underfloor heating system. In this case, the coolant is distributed along the contours not necessarily evenly, but according to the given modes. A comb is needed when their number is more than two. The ratio of the heat carrier flows sets on each circuit a thermal head for a warm floor.

The simplest way is to quantitatively control the temperature of the warm floor through changing the flow rate of the coolant. The flow to each circuit is controlled by the RTL thermal head. It maintains the set water temperature at the outlet of each loop. The sensor is a bellows filled with a heat-sensitive fluid. The position of the valve disc depends on its temperature and the setting of the outer cover with a scale.

A thermal head for a warm floor senses the air temperature in the room and, depending on its size and manual settings for maximum heating of the heat carrier. The upper and lower levels of the control range are limited by locking clamps.

The model may have internal or external threads with which it is screwed to the pipe.

How does the thermostatic head work?

The set temperature of the heat carrier is set on the head scale (photo below).

As soon as it is reached (about 40 0 С), the heat-sensitive element begins to put pressure on the valve stem and shut off the flow of hot water. As a result, the coolant in the loop begins to cool. As the temperature decreases, the thermal head begins to release the stem and the passage for fluid increases. The amount of hot water supplied to the circuit increases and the floor surface begins to heat up again.

Thus, the thermostatic valve controls the temperature of the water passing through the floor heating circuit at a constant flow rate. Only the ratio of hot liquid to cooled changes.

Floor heating mode

The mode is selected at the discretion of the residents. The most common is comfortable or heating. In the first embodiment, the surface temperature is maintained at 28-32 0 C. Here, the heating function of the main room is performed by other devices, for example, radiators. The second option involves maintaining a given air temperature in the room, which should provide a warm floor. For this, room thermostats that control heating are used.

How much fluid passes through the circuit is shown by the flowmeter mounted on the supply manifold. A thermal head for a water floor heating is installed on the return manifold.

The pressure in the system is generated by the central circulation pump of the heating boiler. So that he can push through all the loops, the length of each should be no more than 60 m.

Remote thermal head for underfloor heating

In a heated floor system with automatic control of indoor temperature, thermostats associated with the controller are monitored. The remote room thermostat sends a signal to the servo drive, which controls the manifold valve. In addition, the controller has the following functions:

- response to sensor readings, including outside the house,

- organization of heating modes for certain rooms,

- shutdown and inclusion of heating in separate rooms at different times,

- work with remote control via GSM communication.

Automation costs will pay off over time, because it provides an opportunity to save up to 20% of the funds spent on heating.

Choosing a floor heating system

For one small room, you should choose the simplest floor heating scheme with two shut-off valves and a valve with a built-in thermostat. The maximum water temperature in the circuit is manually set and the thermostatic head will control the valve depending on the room temperature.

If the house is equipped with a radiator circuit, and the underfloor heating is optional, it needs a mixing unit. It consists of a three-way valve, a thermal head and a pump. At high temperature in the house, the return line is closed and internal circulation occurs through the pipes of the warm floor. As soon as the coolant begins to cool, the valve opens again and hot water enters the mixer.

When using a warm floor as the main heating, it is divided into zones, each of which is controlled according to simple schemes. You can equip one large mixing unit for all circuits. Here you will need a controller that sets the temperature limits of the coolant in the rooms.

Conclusion

A thermal head for a warm floor is an essential element in a low-temperature heating system. Together with the thermostatic valve, it is a key element of the system, ensuring efficient use of the coolant and fuel economy. They are both installed when necessary. If you design the right scheme, a warm floor can be installed on your own. The development and installation of a complex system is best entrusted to specialists.

Installation Rules

If the installation rules of the mechanism are not observed, incorrect operation or complete failure of the system is possible. According to manufacturers, with proper installation and operation, a warm floor can last up to 50 years for its owner, so it is important to approach such an acquisition thoroughly.

Reviews

Numerous reviews suggest that a water heating system is popular because of its economy and affordability. Among the factors and selection criteria, people emphasize safety compared to electrical systems.

Among the common manufacturers, the brands WOLF, ACV, VAILLANT, CTC can be noted. Pipes and other accessories on the market are offered by companies such as OVENTROP, WIRSBO, UNIVERSA, AQUATHERM and PURMO.

About what the functional role of the thermal head is in the underfloor heating control system, see the next video.