In pursuit of the traditions of Slavic culture, it is difficult to ignore the log cabin. His houses are built of logs, which are rich in the north. Therefore, modern specialized building materials are still crowded with logs.

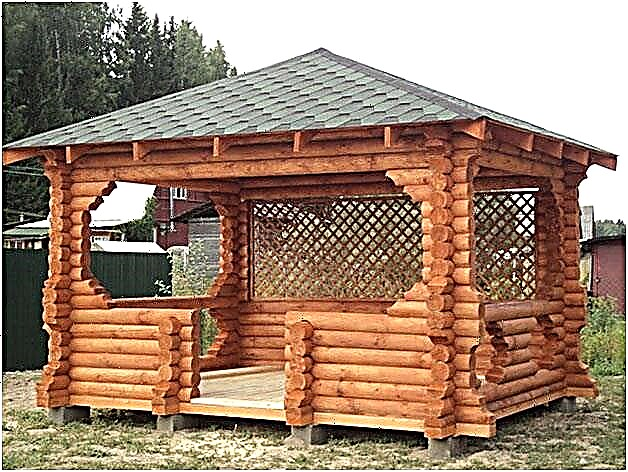

They are so crowded that in landscape design there are often arbours made of logs, which are akin to huts on chicken legs. The thematic log house does not have the latter, but there is an immortal design expressiveness - the muscularity of the logs and their cuts protruding at the corners of the structure.

Types of Logs

Over the centuries-old history of the construction of the log house, carpenters tried to improve the forest area. As a result, he transformed into a different beam. But the log also underwent certain technological changes. It is only at first glance that it seems awkward and monotonous.

In fact, the corresponding building material happens:

- Rounded - rounded and peeled of bark,

- Calibrated - machined mechanically, which makes lumber smooth and even,

- Chopped - obtained by the cutting method.

The latter option makes the thematic design original - with knots, knolls, eyes. In it, each log is different from the others. Typical arbors made of logs are already a laconic log house, which is convenient to erect and caulk, i.e. seal between the crowns.

Calibrated logs, thanks to a smooth and even surface, make the construction of the arbor even easier, but they also cost more than their counterparts.

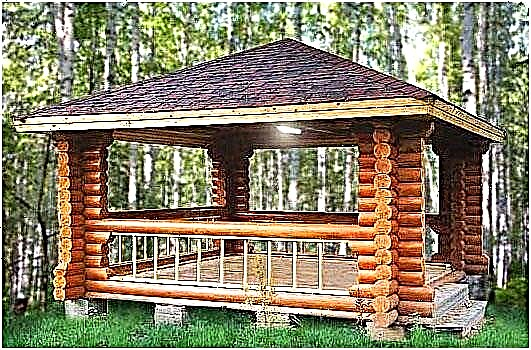

The gazebo is a simple design. It makes no sense to complicate its construction if sufficiently complex logs act as building materials. The best option is open and semi-open structures for summer and demi-season leisure, respectively. Such a log house does not have doors and windows, but can be supplemented with them if necessary.

Building

Before building a log arbor, you need to know its area and shape. Traditionally, a gazebo made of logs occupies no more than 6 m² and is a square or rectangular log house.

The corresponding shape makes it easy to assemble logs in place regardless of the protrusion of their ends.

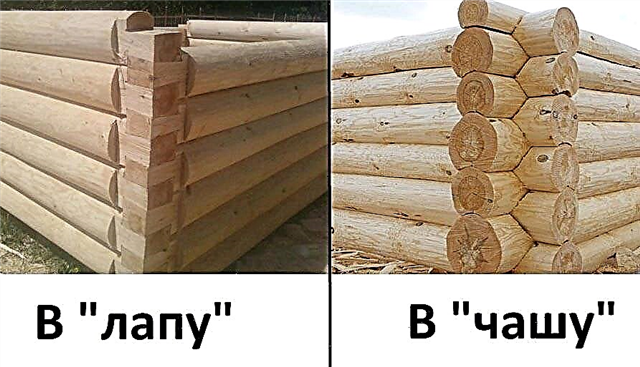

Here it is worth emphasizing that the log house is "in the bowl" and "in the paw." The first option is the traditional one, in which the ends remain round and protrude beyond the structure in the corners.

In the “in the paw” frame, the ends are straight so that their joining is a groove-wedge technique. With it, the ends no longer protrude outside, and the design at the corners is less protected from cold temperature.

Logs can have different lengths - from 4 to 13 m. The diameter varies between 180 and 240 mm.

The construction technology remains the same:

- A section with a wonderful view around

- There is a marking under the strip or column foundation - for stable soil and rocky terrain, respectively,

- Digging a moat or hole under the foundation,

- Depending on the foundation, formwork with concrete screed or brick poles is organized,

- The lower harness is installed in the form of a crown,

- Walls are erected to the desired height,

- Ceiling beams and roof rafters are organized,

- Roofing material is mounted, in which the tile mainly acts.

Although the logs are fixed to each other in the corners of "ohlop" or "oryap", dowels and pins help to improve the fastening of their crowns. Between the crowns, i.e. in rows of logs, caulking is carried out with different fibrous materials - tow, moss, etc.

In a gazebo made of calibrated logs, the surface remains unprotected, so it must be treated with an antiseptic and a flame retardant - to prevent decay and fire, respectively.

For logging, carpenters often use larch or pine. The needles have resins that resist rotting well. Therefore, coniferous logs are resistant to moisture and insects, but ignite well. Larch is stronger than pine, which makes it more expensive

Advantages and disadvantages

The attractiveness of log arbors, especially if the lumber is chopped, justifies the money spent on a thematic log house. It is also quite resistant to bad weather compared to frame arbors. But, unfortunately, there were some disadvantages:

- A high percentage of shrinkage - after the construction of the log house, it is necessary that it ceases to change under the influence of the environment,

- Heavy weight - logs are very massive and inconvenient during transportation and laying,

- The need for a strong foundation - the heavy weight of the logs requires a stable tape substrate.

Therefore, log arbors should be taken thoroughly when the house and the bathhouse have already been erected. In this case, it is not a sin to add two log houses to a third.

If the soil is rocky, and the gazebo is open, then you can limit yourself to a columnar foundation. To reduce the waiting period for shrinkage of logs, their preliminary storage in the open helps. The longer the storage period, the less deformations they should be expected after the construction of a thematic structure

Features, pros and cons of the design

A rounded log is a round-shaped lumber, its dimensions are the same both over one element and in relation to others. It makes neat buildings with smooth walls. For arbors use logs with a diameter of 150-240 mm. For a bearing crown, a slightly larger size is required than for walls.

The most popular coniferous species for cylindering and construction (pine, larch, fir and cedar). They are moisture resistant and last a long time.

Advantages of a gazebo from a log:

- Aesthetics - buildings made of logs are always appropriate in the landscape design of the cottage and do not require additional decoration,

- Quick construction time - the logs are ready for installation, you just need to saw them to the right size and lay them down,

- Long service life - the construction of wood can last up to 50 years, with proper care,

- Environmental friendliness - the material is safe for humans and the environment, moreover, some breeds emit vapors that strengthen immunity and disinfect the air,

- Variability of design - from the logs you can collect any arbor in shape and size.

Like any other building material, rounded wood is not perfect. During the operation of the gazebo, some problems may arise:

- Natural shrinkage. This process is associated with the evaporation of moisture from the structure of the material and can last 2-2.5 years, as a result, cracks and gaps between the crowns may appear. To prevent this, you need to buy wood of natural moisture and regularly treat it with protective compounds.

- Defeat by mold and parasites, rotting, fungus. These troubles arise with increased humidity, frequent contact with water and lack of ventilation. Fight the problem should be aired, if the gazebo is closed, and use special antiseptic coatings for wood.

Whether these flaws appear or not depends on the maintenance of the building and the quality of the raw materials. The most resistant to external influences are larch and oak. But they also require impregnation with antiseptics.

Types of buildings

The design of the wooden gazebo can have a variety of shapes, sizes and functionality. It all depends on personal preferences and budget. When choosing a view, it is worth taking into account the features of other buildings on the site, so that the resting place looks harmonious and does not stand out from the overall design.

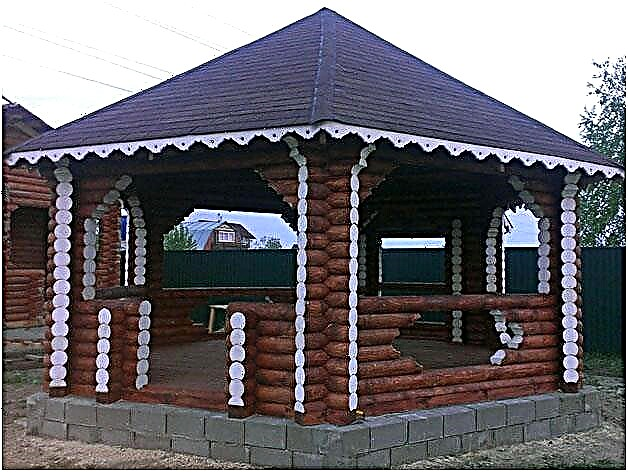

Common geometric shapes of the structure: a square and a rectangle (the simplest in execution), a circle and a polygon (require the preparation of a detailed plan). If the gazebo is large-sized, then the shape of the different parts of the structure can be combined, for example, to assemble a square room at the entrance and a round area for the table and seats.

The geometry of the walls determines the type of roof: gable or four-gable - for simple shapes, and polygonal for complex structures. Roofing material is suitable for anyone, the main thing is that it is convenient to work with it:

- For gable and four-gable - sheet, roll, soft (corrugated board, metal tile, roofing material),

- For round, polygonal and combined - better soft (roofing material, flexible tile, ondulin).

Pergolas also come in:

- Open - when the walls are practically absent and perform the functions of a fence, windows and doors are not provided for in such structures.

- Closed - these are full-fledged rooms with glazing, inside you can place a heater and use the gazebo throughout the year.

- Half-open - are a combined option when the open structure is complemented by a closed room, or the structure has three walls.

Inside the gazebo from the logs, only a table and seating can be located, but if the space allows, they build a place for the barbecue, put a worktop for cooking, a hammock and other equipment that extends the functionality.

The design may be freestanding or adjacent to another structure on the site. When choosing a place for a gazebo, it is worth considering its remoteness from communications, since it is desirable to draw an electrical wiring line and connect lighting, the distance to the entrance to the house, so that it is convenient to carry dishes and products. If a fire source is to be equipped at the site, safety must be taken into account. In this case, leave free space around the structure.

Options and ideas for decorating the building

Rounded logs for a wooden gazebo are connected in two main ways: in a bowl and in a paw. They determine the appearance of the ends of the structure:

- Into the bowl - in this case, the ends protrude beyond the structure, and the arbor resembles a Russian hut,

- In the paw - the logs at the ends are cut off from four sides, and laid on top of each other, forming an angle without protruding parts.

Various variations of the connection methods are possible (Canadian cut, dovetail), but they are all based on these classic species. Suitable for both logs and timber.

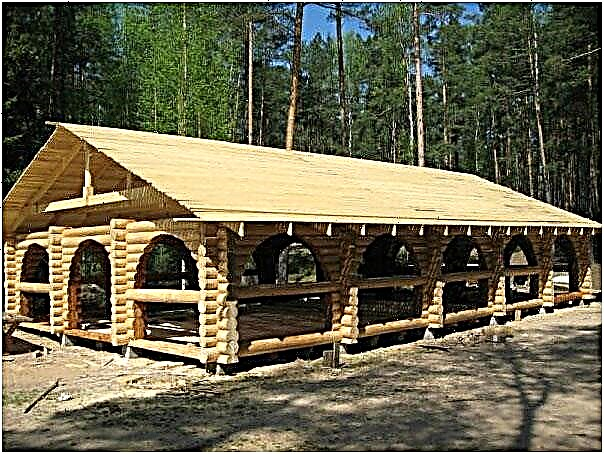

Large Area Arbor Ideas

If large companies gather in the country, you can build a gazebo with a long table and plenty of seating.

In the polygonal arbor you can place a round table. But such a structure will require a fairly large area.

The design with a barbecue or barbecue should be located at a distance from the house and the fence. And it is better to install equipment with a fire source away from the table.

Little Arbor Ideas

To save resources, walls can be made low and the roof high. This option resembles a hut, it is convenient to place a company of 4-5 people in it.

The budget and very compact design will turn out of log seats and a roof without erecting a fence.

A small square gazebo is suitable for reading books or children's games.

Decorating Ideas

Carved decor accentuates the natural beauty of wood. And it will give the building a national flavor.

Gracefully replace the windows and fencing of the lattice of wood. They allow you to save material and provide ventilation to the building.

The natural style of the gazebo is emphasized by clumsy tree trunks, large branches, bark, climbing plants and flower beds.

An interesting effect to the structure is given by the ends painted in a contrasting color. This decor combines aesthetic and protective functions, as saw cuts are the most vulnerable to moisture and pests areas.

Project creation

First you need to prepare and clear the area under construction, measure its area and draw a plan of the gazebo with detailed measurements of dimensions. This stage will allow you not to make mistakes during the construction and purchase a sufficient amount of materials.

When creating a project, it is necessary to indicate the location and dimensions of the openings, the total height of the structure, the location of furniture and equipment inside, if any. At a minimum, the plan should include a side view and a top view.

Preparation of tools and materials

To build a small wooden gazebo, you will need a set of tools: a chainsaw (or electric), an ax, a construction level, a screwdriver, a tape measure, a hammer.

In this case, a lightweight foundation is suitable. It can be built from concrete slabs or make low pillars of brick or cement mortar. For larger buildings, it is recommended to use a strip or solid foundation.

For walls and roof trimming, 20 round logs with a diameter of 20 cm and 4 pieces with a diameter of 22-24 cm are needed. From them, a flange will be assembled. For the roof you will need rafters and boards 20-25 mm, as well as any roofing material. Thicker planed boards (40-50 mm) are needed for the floor, benches and table.

Foundation

Under the slabs you need to dig shallow holes in each corner of the future building. Pour a sand pillow into them and tamp. Next, lay the slabs so that the joints of the first crown of the gazebo are located exactly in the center. Lay several layers of roofing material on top for waterproofing wood. The foundation is ready on this.

Walling

From two thick logs, cut one side - it is necessary that the flange steadily lay on the plates. Lay them on two opposite sides. Make bowls in two more logs of larger diameter. Its depth should be equal to the radius and width to the diameter of the barrel. At this stage, you need to install the logs for the floor.

When laying subsequent crowns along the entire log, a triangular or oval recess is cut down so that the rows fit snugly against each other. The big advantage of the rounded log is that this groove is equipped directly at the sawmill, where they can also cut bowls in the right places.

In a similar way, install 3 more crowns already from elements of smaller diameter. The position of each row is worth checking the construction level.

Further, roof trimming and opening openings are simultaneously performed. To fix vertical logs, you need to use wooden or metal pins. For them, it is necessary to drill holes: one at the end of the new log, the second at the center of the corner joint of the last crown. In order for the upright to be stable, a semicircular bowl is cut down at its end. The same should be on the other side of the log. After securing the uprights, they are tied with horizontal logs using pins.

In one of the walls you need to cut a narrow opening - it will serve as the entrance to the gazebo. In this case, the first log should remain intact.

An example of the preparation of the foundation and the assembly of the walls of a large arbor, see the video.

Roof arrangement

The upper crown will serve as a Mauerlat for rafter legs. For a small roof, three pairs of rafters are enough. One in the center and two on the sides of the gazebo. They should be strengthened with metal corners on the upper crown and the ridge beam.

The crate can be made of timber or boards, depending on the weight and type of roofing material. For corrugated board, a bar installed with a step of 50 cm is suitable. After this, you can lay the roofing and sheathe the pediments with boards.

Installation of floor and windows

To equip the floor, thick boards need to be laid on beams and fixed with screws.If planed lumber was used, then additional coatings can not be laid.

For the design of window openings with gratings, thin wooden battens are required. First, the frame is prepared to fit the size of the opening, then the slats are stuffed diagonally, first in one direction, then in the opposite. The finished structure is treated with protective compounds and fixed in the opening.

Furniture and equipment installation

For a small-sized gazebo-log house made of logs, at least one light bulb is required. The lighting fixture can be mounted on the ceiling or wall, the main thing is that it is protected from moisture.

The table and seats can also be made with your own hands from boards, logs and other materials.

To create a cozy atmosphere, it is recommended to use textiles, flower pots, frames, crafts made from natural materials and other decorative elements in the design.

The cost of the finished gazebo

If you do all the work on the purchase of material, processing and assembly yourself, you can save a lot. But this is far from always justified. If there are no carpenter skills, then it is realistic to make serious mistakes and ruin the building. It is especially difficult to take into account all the nuances in the construction of a complex structure. Therefore, it is worth entrusting the construction of a gazebo in the country from logs to professional craftsmen.

A team of builders in a short time will prepare a plan, deliver and assemble the structure. In this case, any details and features of the site will be taken into account.

The cost of “turnkey” log arbors depends on the area, type (closed or open), complexity of construction, type of roof and roof covering. On average, the price of a building with installation is:

- For buildings with an area of 3x3 meters - from 90 to 170 thousand rubles,

- Pergolas 4x4 meters - from 180 to 250 thousand rubles,

- Large-sized buildings up to 40 sq.m. - 300-500 thousand rubles.

The cost of the construction is influenced by decorative elements, the presence of wooden furniture, additional processing of the log house with paints and impregnations, the conduct and connection of communications.

A gazebo made of logs or beams may become a favorite place in the country. It can be equipped for any purpose and function. If you have skills, then assemble it easily and independently. But there is always the opportunity to order an already finished design made according to a standard or individual project.

Features

The rounded log is a very beautiful building material. It is able to maintain its structure, natural appearance and decorative shape even after prolonged processing. Quite often, logs are used as the main building material for the construction of verandas, terraces and summer houses for summer houses, which are small architectural forms.

A gazebo made of logs harmoniously fits into any project for the construction or improvement of a country house. Particularly often, round timber is used for erecting gazebos near houses whose design is designed in styles such as country or rustic.

As a rule, such a building material as rounded logs is made of pine, larch or spruce wood. However, it should be noted that for the construction of arbors it is best to use logs made of larch, since this particular species of coniferous trees is the most reliable, strong and durable. Logs made of larch are practically not subject to decay processes, which plays an important role in the choice of material for the gazebo. After all, the gazebo is a building that is used for recreation and is located on the street. However, the cost of larch logs is higher than the price of the same logs from other conifers.

During production, the logs are calibrated. The standard size of the log, which is used in construction, is about 180-320 millimeters. The supporting beams of arbors for country houses, cottages or cottages are recommended to be erected from logs, the diameter of which is at least 240 millimeters. The recommended diameter of the logs that can be used for walling should be at least 200 mm.

Arbors, which are built of logs, have their advantages and disadvantages. Their main advantages are:

- high durability

- excellent thermal insulation

- colorful and decorative appearance,

- creating a healthy microclimate inside the erected building,

- excellent environmental performance,

- lack of need for additional finishing materials and extraneous decor elements.

In addition, the relatively small cost can also be attributed to the advantages of arbors made of logs. Therefore, almost any person who has a summer house or a country house can erect a similar design. The only drawback that is present in rounded logs is their low level of fire safety. After all, as you know, wood is a very hot material.

However, this drawback can be eliminated by treating the logs with a special solution that prevents combustion processes.

During the arrangement of the roof in arbors, which were made of logs, as a rule, bituminous tiles, ondulin or euro slate are used. In some cases, as a building material for the arrangement of the roof, a professional sheet can be used.

It should be noted that polycarbonate is practically not used for log arbors. This is due to the fact that it is a very light material. In addition, the appearance of polycarbonate can significantly distort the decorative characteristics and visual perception of the gazebo itself.

For installation of floor coverings inside arbors paving slabs, decorative stone can be used. However, in most cases, for the manufacture of floors in such buildings, ordinary wooden boards are used if it is not planned to place a fireplace or barbecue inside the building.

Projects

Wooden arbors made of large logs can have different sizes, shapes, and also differ in functionality. The most common geometric shape of these structures is a square or rectangle. This is due to the fact that buildings with just such geometric shapes are easiest to erect, especially if you use ready-made projects for this.

In some cases, arbors can be built in the shape of a circle or polygon. However, it should be noted that buildings erected in the form of such geometric figures need a detailed development of the construction plan and thorough preliminary preparation.

In the event that the arbor is bulky, then the shapes of its parts can be combined. For example, at the entrance to the gazebo, the room can be made in the form of a rectangle or square, but the recreation area can be made in the form of a circle.

The geometry of the walls of the building determines what kind of roof will have it. Roofs that are erected on buildings of simple shapes (square, rectangle) are gable and four-gable. The polygonal roof, as a rule, is erected on buildings that have a complex structure. Roofing material can be used almost any (metal tile, roofing felt and so on).

Arbors are of several types:

- Open type. There are no walls in the building, and the installation of doors or windows is not provided.

- Closed type. They are full-fledged rooms for rest, in which glazing is present. Inside such buildings, as a rule, there are heating devices that allow them to be used throughout the year.

- Half open type. They are a combined version of the building structure of the open type, which is additionally equipped with a room isolated from the external environment.

Inside the open type arbors erected from a log, as a rule, only a table, chairs or benches can be located. However, if the building has a lot of free space, then inside it you can additionally build a place for a barbecue or smokehouse.

By its design, the arbor can be located separately or adjacent to some building, for example, to the house. When choosing a place for the construction of the gazebo, it is necessary to take into account its remoteness from the nearby communications. After all, after the construction of such a building, lighting will need to be brought into it.

In the event that it is planned to place sources of fire inside the building (barbecue, smokehouses, barbecue shops or even fireplaces), then around it, to comply with safety rules, you need to set aside some free space.

Materials

You can use chopped materials for the log house. Often cylinders are used - logs of a cylindrical and calibrated type.

In the construction of wooden arbors from logs, you can use wood of different species. For the manufacture of the supporting part of the building, you can use pine, fir, cedar or oak logs. It is these tree species that are able to cope with the loads that arise during the operation of the building. In addition, they have increased resistance to rotting processes and are wear-resistant.

A pine beam is practically not subject to decay processes and perfectly tolerates moisture. Due to its low cost in comparison with other types of building materials, it is most popular during the construction of wooden buildings.

Immediately before the start of construction, the logs must be subjected to additional processing. For example, in order for wood to be more resistant to moisture, it can be treated with a special solution. To ensure fire safety of a wooden building, the bars are treated with flame retardants.

Tips & Tricks

By and large, the gazebo made of wooden logs is a summer pavilion that is used during the holidays. Such wooden buildings are very popular in central Russia. Such a building can solve several problems:

- to decorate the site on which it was built,

- to act as a pavilion,

- used as the main place to relax.

However, in order for the gazebo to be a cozy place for daily rest, it must be properly designed and built. It is very important before construction to correctly determine its location on the site. When building a wooden gazebo, it is recommended to leave a little free space around it and design its structure so that it is freely accessible.

Just before the construction of the wooden gazebo, you need to take care of the foundation on which it will stand. As a rule, buildings, during the construction of which logs were used, are massive. Therefore, it is recommended that they prepare the foundation of the tape type in advance.

At the initial stage, you need to prepare a place on the site and correctly make the markup. Then, along the estimated perimeter of the future gazebo, you need to dig a shallow ditch. At the bottom of the moat you need to pour a small amount of sand and cover it with roofing material. Then, at the bottom of the moat, bars are installed to which the reinforcement is fastened, the diameter of which should be at least 12 millimeters. Then the moat must be poured with concrete.

Before you start laying logs, it is necessary to lay several layers of roofing material on the foundation surface. It plays the role of waterproofing and protects wooden logs from the harmful effects of moisture.

The walls of the arbor from logs can be erected using several methods. The first method is called "into the bowl," and the second is called "into the paw." When laying the logs “in the bowl”, small ledges remain at the corners of the building. As a rule, this method is recommended to be used in the case of the construction of arbors, which are planned to be used for relaxing in the winter season and heated by additionally placing a fireplace in them.

The second way of laying, which is called "in the paw", implies immediately before the installation of logs making special grooves in them. The walls of buildings that were erected in this way have no protrusions and visually look absolutely flat.

As a rule, the walls of wooden arbors do not need additional decoration. However, if the gazebo is a capital building, then in this case one or even two of its walls will be deaf. As a rule, such arbors are planned to be used in the winter season, which means that the inner part of their walls needs additional decoration.

You can finish the internal walls of the gazebo with an ordinary clapboard or special paint. Also, the most ordinary plaster, which is then additionally covered with emulsion paint, is perfect as a finishing material.

The capital building, which is planned to be used in the winter season, should also be well insulated. Moreover, it is necessary to insulate not only the inner part of the walls, but also the roof, as well as the floor of the structure. To warm the floors, you can use carpet, laminate or particleboard. To insulate the roof and ceiling, you can use special panels that are made of foam. Today it is the most popular material used for insulation of house facades.

Beautiful examples

There are a huge number of design options for wooden arbors made of logs. Each has its own specific advantages. When planning the design and form of the building being built, first of all, you need to decide what exactly this building will be used for. For example, if on a personal plot you need a gazebo for tea, then in this case a small-sized building is perfect.

A long rectangular gazebo is perfect for a comfortable stay of large companies. Inside such a building, you can mark out a long table and a large number of seats.

In the gazebo, which has a polygonal design, you can easily place a round table. However, the construction of such a building on the site will require a large amount of free space.

In order to save resources and space on the site, you can build a small-sized gazebo with low walls and a high roof. This type of building is perfect for relaxing a small company of 5 people.

See how to build a gazebo from a log in the next video.

Advantages and disadvantages of a gazebo from a log

The main advantages of a gazebo from a log:

- Attractive appearance, compatible with nature and the surrounding landscape.

- For construction, an environmentally friendly building material is used, which is not capable of harming human health.

- The tree is able to "breathe", which means it provides good ventilation, so that fungi, mold and other harmful bacteria do not appear on its surface.

- Wood has good sound absorption characteristics.

- Quick and easy construction.

- There is no need to purchase finishing materials, it is enough to process the wood with natural mixtures and antiseptics that protect it from external factors.

A log, like any building material, has not only positive aspects, but also disadvantages. The disadvantages of such structures include:

- The need for regular care and processing of wood so that it does not crack or rot.

- Fire hazard of wood.

- The complexity of grinding and processing material.

The choice of building material

To create a gazebo, various types of logs are used, namely:

- Round log - a log that is produced on special machines and after processing receives a standard diameter, due to which all logs are identical, which is convenient in construction. Often a round log is used, characterized by good air exchange and low thermal conductivity. At the same time, the material is heavy, requiring a solid foundation.

- Calibrated - a log that has been machined along its entire length to obtain a certain diameter. As the basis for calibrated logs, aspen, linden or oak, dense spruce or soft pine are used. The material has an attractive appearance and smooth surface; it is used for the construction of buildings of various types. Main advantages: attractive appearance, protected from moisture, has low thermal conductivity and low weight.

- Chopped log - has an attractive and neat appearance. The main advantage of the gazebo made of such material is the most natural appearance.

Types of designs

Wooden arbor can have a different shape and dimensions, which means it can easily fit into any area, regardless of its area. If the site is compact, then on it you can place a small square gazebo, the dimensions of which will be 3 * 3 meters. The roof is gable or four-gable, the roofing material is slate, flexible tiles. An alternative solution for a small area is the extension of the gazebo to the house with the additional installation of a stove or barbecue.

It is possible to supplement the design by making it more expressive and attractive by installing grilles or carved elements. You can also use logs of different shades, creating an unusual color combination. A rectangular log arbor is a classic solution for building a wooden structure. More original options are the construction of a six or octagonal gazebo.

Arbors from a log can differ among themselves not only in shape, but also in type of construction:

- Open - a simple gazebo that has no walls or window openings. As a fence, a wooden fence of various types of openness and height is used.

- Closed - a small house with full doors, walls and windows. Having warmed the space, you can turn it into a guest house or a gazebo for year-round recreation.

- Semi-closed - a structure that has 2-3 walls and serves as a seasonal building.

Self-construction of a gazebo from a log

Do it yourself step-by-step construction of a log arbor with your own hands:

- Preparation of the place where the gazebo will be located. Cleaning the area, removing the topsoil and chemical treatment to protect against weeds.

- Land leveling and marking.

- Foundation production (strip, tile or column), the choice of which depends on the presence of the furnace and the total weight of the structure.

- Digging trenches, installation of formwork and "pillows" of sand and gravel.

- Concreting and laying of waterproofing.

- The construction of walls on the principle of "in the paw", to pre-mark the logs at the ends.

- Four-edged log processing.

- Perform horizontal stacking of logs using the building level.

- Carry out a vertical connection using the pins.

- Perform caulking (one year after the construction).

- Installation of the roof (rafter base, lathing, waterproofing and roofing material).

- Finishing and processing.

Varieties of log arbors

But in this type of building there are still subspecies. And there are a lot of them. They depend on the shape of the structure, type of construction, type of material, type of roof.

Let's start with the form:

- Oval

- Square. It will be quite suitable for a small area, when the arbor from the log itself will be 3 * 3 m. If your site size is small, you can still choose the construction option, when the walls of the house and the arbor adjoin each other. This option looks quite interesting. Since the structure itself looks simple in this type, it can be decorated with carvings or gratings. In this case, you can combine the logs dark and light.

- Rectangular Such projects of log arbors are in great demand. The size of such a structure is usually 3 * 4 or 3 * 6. It is better to resort to this type of arbor when it allows a sufficiently large space on the site. You can also decorate with carvings and compounds of different colors of wood.

- Six-, octahedral. Interestingly, this type of gazebo saves space even more than square. This is achieved through such an intricate form. But at the same time, the size inside remains quite capacious.

- Curly. This type of cottage is usually considered by people who want to have a unique landscape. You can find a gazebo resembling a fireplace, a tree, a castle, a carriage, a mushroom and many others. For the construction of a figured gazebo, of course, it will take a lot more time, money and space.

- Minimalism. If you do not have the desire or the ability to build one of the mentioned species, you can think about a mini arbor. It consists only of supports, as well as a canopy. A small group of friends will still fit there. Only there will no longer be such protection against wind and bad weather, as, for example, in its other types.

Figured arbor

Figured arborAlso, arbors differ from each other by the type of structure:

- Open. These buildings do not have windows or even walls. Only fencing to support the roof. In good weather, rest in such an area will be very comfortable. After all, we rest in nature because of the fresh air, which is achieved in such a gazebo. But on a day of bad weather you can’t sit in it comfortably.

- Closed. They have windows, walls, and also a door. You can call such a building a mini-house in which you can take loved ones in any weather. Someone arranges a summer kitchen inside.

- Half closed. This subspecies contains elements of the first and second type. They have 2-3 walls and a roof. To some extent, hiding from the wind, precipitation will be possible, but not completely.

The next distinguishing feature is the material from which they are built. The following types can be distinguished:

- From the boards. Such material is cheaper than others. You can use it with any buildings in the cottage of wood. It is worth considering that during the installation of the frame it is better not to use one-piece joints, because then you often have to change, improve something in the structure during the construction of the gazebo itself.

- From calibrated logs. For this type, each part is operated separately at the sawmill mechanically. Thanks to this, the logs are the same and smooth. Even private houses are built from this type of material. It is possible in advance at the sawmill or in the company to order additionally to make openings for the joints of logs. Such parts look very neat, so they may not even be processed additionally. Often calibrated logs are complemented by a prepared profile. He protects them from the subsequent possible decay and destruction of the building. This beam can retain heat indoors. Therefore, in the cold season it will be comfortable to relax in such a creation. Due to the light weight, the foundation for the building can not be made too massive, which will save time and money. Calibrated logs can be made from soft pine, dense spruce, oak, linden and aspen.

Arbor from the calibrated log

Arbor from the calibrated log - From planed or chopped logs. Such raw materials are processed manually, as before, using an ax and a planer, but not modern processing methods. In this way, a view typical of this type of arbors is achieved that is close to natural nature. Such buildings are perfect for any landscape. Experts say that it is better to cut a tree for a log house in winter. At the same time, you still need to make the most identical log sizes. After the tree was cut down, you need to immediately remove the bark and independently prepare the castle so that the assembly of the log house takes place qualitatively. Arbors from planed logs are not only with one floor, but also with two. On the second floor between the racks you can hang a hammock. This will make your house even more attractive. But you can stay on a standard structure.

- From the rounded log. Their significance and features will be discussed later.

Now you can see how the arbors differ in the shape of the roof.

- From natural materials: wood, shingles, bulrushes, etc.

- From artificial: ruberoid, slate, tile, etc.

The pavilion can be additionally equipped with a heat source (electric collector, barbecue, etc.), appliances and others. This will help to make the place more comfortable. But it is worth considering all the details so that attackers, as well as bad weather, could not harm your property.

Distinctive features of the rounded logs

Such homes include elegance, beauty and luxury. This style will look in the construction of baths and houses as well. In the log buildings traced the spirit of country, Provence. This is especially reminiscent of the rustic style, which in our mind is always associated with calm, silence and childhood. In the bustle of today, most likely, everyone will want to plunge into such a vacation. An important uniqueness of rounded logs can be called the same diameter of the entire log house. This is achieved through special woodworking machines at the company. It is impossible to achieve the ideal size on your own. Due to this uniform size, the arbor from the log is quite neat and cannot be left without special attention of passers-by. The diameter of the log house is usually from 18 cm to 32 cm. But for the gazebo, you should choose a diameter in the region of 15-24 cm. Although it depends more on the preferences of the future owner, his budget and design. It is also worth noting that when buying materials, it is important to clarify whether trim from previous designs was used in the manufacture. Only a whole and high-quality blockhouse! For construction, most often the choice falls on conifers. It can be spruce or pine. Here, price and quality justify each other well. Less often use oak, larch and cedar due to the high cost. Although such raw materials also fit perfectly into this style.

Arbor made of logs

Arbor made of logs

The advantages of logs and structures made of them

It is rare that convenience, beauty and price delight a customer. But here is exactly the case. Here are some of the advantages that may encourage you to focus on this type:

- Easy assembly. At the same time, strength and stability of the building due to ideal logs are maintained.

- No need to process separately. As a rule, even at the sawmill, the tree undergoes a special degree of protection against decay. After the purchase, you will no longer need to waste time for this.

- Fast construction erection. This is achieved due to the uniform size of the logs. This stage will take literally several days.

- Good sound absorbing performance.

- High thermal insulation. Since the logs are adjacent tightly enough to each other, heat is not lost. Separate wall insulation is not even required. This adds special comfort in the cold season.

- The durability of the building. This is again achieved by the same elements.

- Not harmful to health. Arbours from wood do not emit hazardous substances, therefore they are considered safe. Due to the good ventilation of the tree, dampness does not accumulate on the surface and indoors, which also has a beneficial effect on health.

- Suitable for any landscape. Since wood is a natural material, planning a construction project will not be difficult.

- It does not require additional decoration. From time immemorial, the tree itself has been considered a luxurious element of the interior and decor. Even if you decide to abandon the special finish on the outside or inside the gazebo, it will not lose its unique beauty.

- Preservation of village charm. Although the arbor made of logs looks strictly, it does not interfere with reaching the beloved rural style.

- Price justifies the quality of the building.

Rectangular Log Arbor

Rectangular Log ArborPossible cons of the log house arbor from logs

However, as in everything, in arbors made of logs have their drawbacks. Consider the following:

- Over time, the building can sit down due to evaporation of moisture from the logs. This may take 2-2.5 years.

- To care for the log arbor, special processing aids will be required. Otherwise, the tree will crack, rot and become a home for unwanted guests. Materials from specially treated pine are less susceptible to such a sad outcome. Impregnation of the log house should be carried out every 3-5 years.

- After the building shrinks, gaps may occur between the elements of the gazebo.

- Log arbor is a fire hazardous raw material, as it is not processed strongly and qualitatively. Therefore, you should be very careful with the use of fire indoors and near the building.

- It is difficult to chop this type of log. Although grinding is relatively easy.

Arbor made of plastic bottles

Arbor from a bar

Methods for connecting logs to a bowl or paw

Log arbors are assembled in two ways: “into the thicket” and “into the paw”.

- The “paw” or “dovetail” method is more popular. The essence of such a connection is that at the joints of the logs do not go beyond the building. Less effort and time is spent on it, but more qualification for a more proper connection. But in this method, the gazebo from the log house will not last long due to the fact that at the junction of the fiber the logs rot faster.

- The “in the bowl” method involves logs superimposed on each other due to semicircular recesses. In this case, the log house should protrude 25-30 cm. In this method, the logs are very tightly joined to each other. Corners in such arbors do not freeze and dampness does not accumulate on them. Such a connection looks more attractive than the previous one, but the material comes out 15% more.

Methods of joining logs in a bowl and paw

Methods of joining logs in a bowl and pawIn terms of strength, these two methods are not particularly different from each other, so the choice depends more on your preferences and capabilities.

Do-it-yourself or do-it-yourself price difference

Most often, doing something with your own hands is cheaper than ordering it. Let's look at one example of how impressive this difference is. An open gazebo with a size of 3 * 3 and a height of 2 meters will require about 5 cubic meters of raw materials. The average price of 1 cubic meter of logs is from 8 thousand rubles. So only a tree will take about 40,000 rubles. Plus 1000 rubles for small things (screws, nails). And another plus the roof comes out about 30,000 rubles, if you take such less or less cheap material as ondulin. That is, about 80,000 rubles will be spent on materials.

If you order a “turnkey” gazebo, then this type of building will come out at least 110-120 thousand, which is clearly more expensive. 1 square meter of an open arbor made of wood averages 16,000 rubles, closed - 23,000 rubles. The company from which you will place an order can also lay the foundation for the gazebo. But the cost for it must be negotiated separately, because it depends on the type and size of the base. At the same time, you save your time and energy. Since professionals will fulfill your order, you can also be calm about the final type of arbor and save your nerves during construction.

Step-by-step construction of a gazebo from a log

If you still decide to make a gazebo of logs with your own hands, you need to examine in detail each stage of its construction. Let us now dwell on this topic in more detail.

Build a gazebo

Build a gazebo

For the construction of a chopped arbor made of wood you will need the following materials:

- Everything for the foundation (cement, crushed stone, reinforcement mesh, sand, formwork materials)

- Wood

- Self-tapping screws and nails

- Hacksaw

- Bituminous waterproofing

- Means for wood impregnation against burning (if it was not agreed in advance to do this at the company)

- Marking rope

- Cement

It is also important to choose good tools for fast and high-quality work, such as:

- Hand, electric or chainsaw

- Hammer, ax

- Concrete mixer

- Screwdriver or drill

- Shovel

- Building level

- Construction knife

Log processing

Log processingConsider each view in turn

- Tape. First you need to dig a trench in the ground, depending on the layout. The width, as a rule, is 25-30 cm, and the depth varies from the degree of freezing of the soil. Such a foundation can be of two types: one-level and two-level. The first crown is most susceptible to pressure and the risk of decay. Therefore, it most needs special treatment. It is better to make it from powerful materials that differ in thick logs. These include, for example, oak and larch. In the case of a two-level strip foundation, the first log is cut to half lengthwise and is installed on the foundation previously passed waterproofing. It is extremely important because it serves as a barrier to the transfer of moisture from cement to wood. When installing logs, better use a level for accuracy. On the opposite side, the same work needs to be done. The third log needs to be cut so that it fits snugly on the previous logs and on the base. All subsequent logs are laid according to the same principle.

Foundation for gazebo

Foundation for gazebo With a two-level foundation, a cut on the first log does not need to be done. After the formwork is in place, a pillow of sand and gravel is poured into the trench.

- Columnar. At the corners of the upcoming frame, recesses are excavated and the formwork is mounted. After this, the pits are filled with crushed stone and poured with concrete. If the last layer has already dried, you can proceed to laying roofing material for waterproofing.

- Tiled. This foundation method is provided for an open gazebo. For him, you need to dig a depression along the entire width of the future building at 4 m depth and fill this space with rubble. Lay the grid of reinforcement from above and pour concrete on everything.

If the piece of land on which you decided to build a gazebo has a slope, instead of the already considered foundation options, it is better to use screw piles. Then both the cost of the foundation and the time for its construction will be minimized. To connect these racks to the foundation, logs are mounted on reinforcing pins. And on top of the perimeter are the belt bars for ligaments. Instead of piles, columns consisting of bricks and concrete can also be used.

If the gazebo is used exclusively in the summer, ordinary trampled soil or a mixture of sand and granulations will be sufficient for the foundation. To make such a pillow, we remove the top layer of the earth by 15 cm. 10 of them are filled with sand, the remaining 5 with granulation.

Designs of log arbors include flooring. What material it will be made of depends on whether it will be used in the cold season or warm. If all year round, then it is better to make the floor more thoroughly and to install a wooden coating on top. If the gazebo is closed, doors, walls and windows will protect the tree from the negative effects of the environment. Of the many types of flooring can be made of:

- Board

- Laminate flooring

- Tiles

- Asphalt

- Clays, etc.

Laying tile floor for gazebo

Laying tile floor for gazeboConnections between log cabins

As we already know, there are two types of connections: “into the bowl” and “into the paw”. What they are characterized and different from each other, also considered. Now we can move on to discussing how to fix connections. To do this, use a wooden nail, which is also called a dowel. It needs to be made a couple of centimeters shorter than the hole that was made for it at the junction of the logs. When the gazebo shrinks, the plug will be just right.

The walls of the arbor made of logs

For starters, you need to make markings at the ends of the logs. When the first log has already been installed, it should correctly mark the other logs. Four edges are pulled through the bars, one of which must pass through the entire length and leave a little more. To correctly perform the grooves in the log, you need to visually divide the square into 8 parts. It is very important to adhere to the rule that each log is set horizontally and checked by level for reliability. About a year after installation, complete shrinkage occurs and then caulking can be done.

Bearing supports can be of two types: vertical and horizontal. Your choice affects the further installation and the type of upper trim and roof.

Roof

For the erection of the roof, a rafter base should be used. Choosing a crown, the shape of the roof will be semicircular or conical. The number of slopes can vary from 6 to 8. And you can use the ridge beam. In this case, the roof will be gable. The upper harness and the rafter base, as well as the details in the base itself, can be interconnected with wooden pegs. After this stage, the crate is laid and the turn of the final part of the roof is suitable. The profiled sheet and metal tile are screwed to the rafters with self-tapping screws. And when choosing a bituminous roof or tile, you need to lay a moisture-resistant plywood in one layer.

Decoration of the roof of a wooden arbor

Decoration of the roof of a wooden arbor

Possible errors in the construction

If you have already read up to this point, then you definitely decided to work on your gazebo at home or in the country with your own hands. Then let's pay attention to what mistakes should be avoided during such construction.

- The place for the gazebo should not be in the lowlands. By its nature, land in a lower location has increased moisture. The tree is very afraid of moisture.

- The angle of the roof should be chosen correctly. Then snow and water will not accumulate much on the surface.

- It is important to adhere to the construction plan in order to avoid unpleasant surprises when there are not enough planned materials or the building does not match the intended design.

- The construction of the arbor made of logs should take place exclusively in dry weather.

- During planning, it is important to consider the supply of electricity, as well as how the room will be ventilated.

- Between the base and the first crown should be waterproofed to avoid excess moisture. For the floor and the lower log, it is better to choose logs from relatively waterproof species.

Arbor arrangement inside and out

When the most basic work with the gazebo is finished, you can turn on all your remaining fantasy and direct it to the last, most pleasant stage - the design of the internal and external parts.

- Floor finish. It must be treated, firstly, with an agent against dampness and moisture. If a wooden floor was chosen, then it should also be varnished or facade paint.

- Fancy windows. They can be of the most unusual forms. They can be left through, unglazed. And the size can reach even almost half of the area of fences

Arbor arrangement

Arbor arrangement - Lattices. Such a detail can also be made of wood. In combination with a tiled roof, this element will be perceived in a special elegant way.

- Contrast in shades. By making the ends of the logs white and covering the sides with a stain, you will achieve a pleasant transformation of the building.

- Brazier. When the log semi-open gazebo is made with a conical roof of a chocolate shade, and it itself has a light color, you can put a large brick stove with a fireplace inside. It will turn out a kind of summer kitchenette. Opposite the heat source, we put a round table and some chairs. Such arbors look very luxurious and attract the views of others. Or, if you decide not to put the brazier inside, you can allocate a special place for it near the entrance. Just keep in mind that a canopy must be present for the fire.

- For a comfortable way to the gazebo and back, it is better to make a path of stone or tile

- If the arbor from the rounded log is made not open, then not far from it you can arrange a small place. In good weather, you can make a table and relax in nature with fresh air.

The following elements will also add decor:

- Forged parts

- Weather vane on the roof

- Decorative gate at the entrance to the gazebo

- Flowerbeds, climbing plants

- Figurines

- Lighting

- Rocking Chair (inside)

- Pillows, curtains (inside)

- Indoor flowers (inside)

Gazebo with barbecue

Gazebo with barbecueCare for a wooden gazebo

To extend the service of a wooden gazebo, follow these three rules:

- In the cold season, if the gazebo is not open, cover with stretch film. Make small holes to avoid moisture.

- Regularly treat wood with products designed to prevent rot, parasites, destruction and fire.

- Make sure that in the fall the leaves did not linger in the gazebo. Then you can avoid rotting logs on the floor.

Adhering to the tips discussed in this article, you will be able to create a comfortable, unique log cabin in which you, your friends and family can enjoy your vacation in any weather.