XB-0278 primer-enamel is a three-in-one composition, namely it combines the properties of a rust converter, primer and enamel.

This type of paint and varnish products has been gaining positive reviews among consumers of chemical resistant paints for more than a dozen years.

HV 0278 primer-enamel is intended for painting metal surfaces, the cleaning of which is difficult due to a number of reasons: large-sized products, a complicated profile of the treated surface, the presence of scale and tightly adhering rust (layer up to 75 μm), adverse weather conditions during application (surface fogging).

Enamel XB-0278 is intended for painting various metal structures: gratings, fences, garages, etc., can be used in the repair painting of a car for priming rusty surfaces, bottoms, wings and other details that do not need decorative painting.

The composition is applied as an independent coating in 2-3 layers (1 layer acts as a rust converter, 2 as an anti-corrosion primer, 3 as a decorative coating).

Soil-enamel can be used for protection (in a complex multilayer coating with weather-resistant enamels, varnishes such as ХС, ХВ, МЛ, ПФ) of equipment and metal structures exposed to salts, aggressive gases and other chemicals having a temperature of no higher than 60 ° С.

In this case, the primer-enamel can be applied over old coatings and overlap paintwork from the above.

The coating, consisting of three layers of CV-0278, in a temperate climate (U1) retains protective properties up to a score of no more than AZ1 and decorative properties up to a score of no more than AD3 according to GOST 9.401-91 for 12 years, in cold climates (ChL- 1) protective properties up to a score of AZ1 and decorative properties up to a score of not more than AD3 according to GOST 9.401-91 for 5 years.

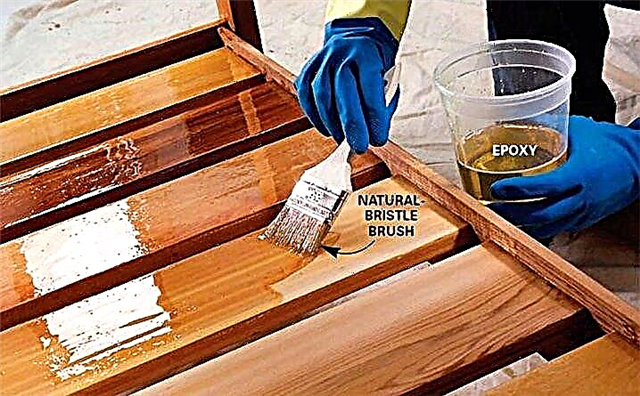

XB-0278 is applied to the surface by pneumatic spraying, brushing, dipping.

To working viscosity, the primer XB-0278 is diluted with solvents R-670, R-670A, R-4 or R-4A.

The color of the film is any according to the customer’s request, including silver and according to the RAL catalog.

Film color

. red brown, gray, blue, yellow, black

Viscosity VZ-246 viscometer with a diameter

4 mm nozzles at a temperature of (20 ± 0.5) ° С, s, not less than

. 20

Mass fraction of non-volatiles,%:

- red-brown, yellow, blue

. 35±2

Drying time to degree 3 at temp. (20 ± 2) ° С, h, no more

. 1

Hardness of a film, not less, according to a pendulum device of the type:

- TML (pendulum A), rel. units

. 0,21

- M3, conventional units

. 0,35

Bending elasticity, mm, not less than

. 1

Coating strength upon impact with U1 device, cm, not less than

. 45

Film adhesion, points, no more

. 2

Resistance of coating to the effects of a 3% NaCl solution, h, at least

. 72

Warranty period of storage - 12 months from the date of production.

Standard

By type of material

Enamel primer, Primer, Enamel, Other

By type of surface to be protected

Ferrous metals, Primed metal, Rust

By application

Railway engineering, Bridge constructions, Oil and gas complex, Agricultural machinery, Construction machinery, Shipbuilding and ship repair, Metal structures / Steel structures, Buildings / Structures, Automotive industry and auto repair, Military-industrial complex / Defense, Pipelines / Engineering constructions

By special properties

Corrosion protection of metal, Wear-resistant coating, Rust painting, Car repair materials, For outdoor use, Matte / Semi-matt, For interior use, Frost-resistant materials, Quick-drying coating

Resistance to impact

Moisture resistance, Wear resistance, Corrosion protection, Gas resistance, Resistance to mineral fertilizers, Resistance to detergents, Chemical resistance, Weather resistance, Oil resistance

Description and purpose of enamel

HV-0278 primer-enamel is a type of primer that additionally has the properties of an enamel, a rust converter, that is, it combines all three means in one. This paint and varnish product is not a novelty in the market: the manufacturer Antikor-LKM has been producing it for more than 15 years.

Scopes of a primer are various:

- Covering any structures in industry, everyday life.

- Painting of machines, units that are exposed to steam, gas, chemicals, reagents, liquids with temperatures up to sixty degrees.

- Painting of metal surfaces (steel, cast iron) on which there are soot zones.

- Work on sections of rust, the depth of which does not exceed 100 microns.

- Processing lattices, garages, car parts, fences, gates, stairs, products with large dimensions and a complex profile.

- Primer for parts that do not require a decorative coating.

- Creating a base for refractory coatings.

The cost of soil-enamel is about 120 rubles per liter, available in packs of 1 - 25 liters. The service life of the material after creating the coating film is about 5 years. If necessary, you can purchase more modern tools that last up to 15 years, but their cost is much higher. In recent years, the manufacturer began to produce XB-0278 primer-enamel with the addition of pigments - you can buy a tool in black, blue, blue, gray, brown, yellow.

Enamel composition

The chemical composition is represented by the main component - perchlorovinyl resin, a number of additional fillers. This resin is used in the manufacture of pipes, bathtubs that regularly come in contact with an aggressive environment, while creating varnishes and paints with corrosion protection.

Other enamel components:

- epoxy resin

- alkyd resin

- pigments

- plasticizers

- corrosion inhibitors and rust converter.

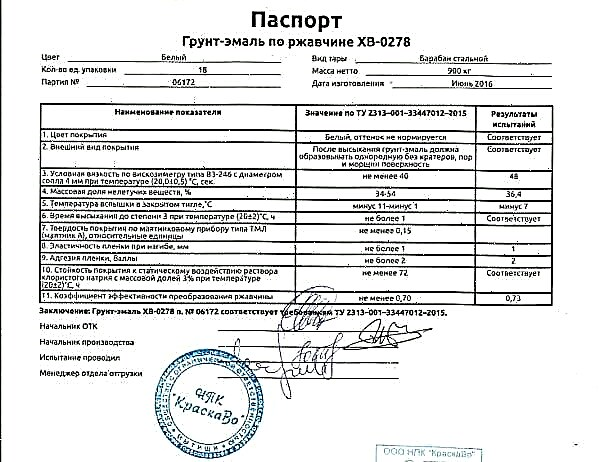

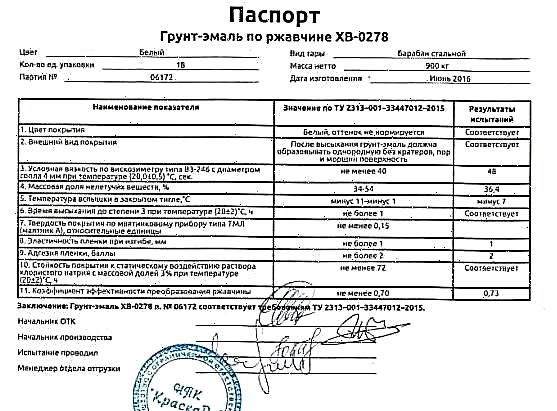

Specifications

The paint and varnish product is produced in accordance with GOST, its composition and technical specifications are approved by official certificates. The description of the product indicates the specific properties of the enamel itself, the quality of the resulting protective film after application.

The main indicators of primer-enamel are as follows:

- conditional viscosity - VZ-246,

- the amount of non-volatile substances - 35% in non-ferrous products, 31% - in black,

- consumption rate per 1 m2 - up to 150 g,

- the drying time of the product is 1 hour (temperature - about 20 degrees).

The resulting film is dense, uniform, matte. Her technical indicators:

- layer thickness - 20 - 25 microns in the first, 20 - 40 - in subsequent ones,

- the number of layers on the product is two to three,

- the degree of milling of the layer is not more than 40 microns,

- bending elasticity of the coating - from 1 mm,

- film adhesion - 2 points,

- the hardness of the pendulum device is 0.15,

- resistance to sodium chloride 3% - from 72 hours,

- rust converter efficiency (coefficient) - 0.7.

How to apply enamel

Priming should be done after preliminary preparation of the surface, which may be rusty. Loose rust should be thoroughly rubbed before separation. It is necessary to remove the remainder of the previous coating, scale, dust, dirt, using solvents.

Proper storage

In order for the coating to be of high quality, the storage conditions of the product must be observed. It can be transported by any means of transport, but the air temperature should not exceed 30 - 35 degrees Celsius.

During transportation and storage, strict observance of the conditions for the protection of enamel from atmospheric precipitation is required. Storage does not allow exposure to sunlight or moisture. The container is tightly closed during storage. Permissible storage temperature: from -25 to +30 degrees. Compliance with the conditions guarantees excellent properties of the product up to six months from the moment of production.

Breeding order

How to dilute enamel? For dilution using solvents R-4, R-4A. The same means can be used for preliminary preparation and cleaning of the surface from pollutants. It is permissible to use diluents R-670A, R-670.

Specific dilution rates are not indicated, the viscosity of the finished product is determined by the application method. When applied directly by roller or brush, the mixture may be thicker than when sprayed from a spray bottle.

The solvent is added in small portions, each time thoroughly mix the mass. After applying the primer to the surface, the solvent evaporates quickly, and the coating remains strong. You need to work with solvents by wearing a pair of gloves, protecting the respiratory system with a respirator, and skin with thick clothes.

Enamel application

Apply XB-0278 primer-enamel in different ways:

- airless spray

- pneumatic spray

- roller

- with a brush

- dipping into the product.

Air temperature during work: from -10 to +30 degrees, humidity - 80%. The first layer should be dried for 1 to 2 hours (temperature - twenty degrees). The remaining layers are applied every hour. Two or three layers are sufficient to provide a stable coating, the first serving as a rust converter, the second as an anti-corrosion primer, and the third as a decorative coating.

Basic mistakes when using

Most often, users allow such erroneous actions when working with a primer:

- Application of only one coat. Some to save only one layer of the product - this is the wrong decision. Two or three layers are necessary according to the instructions to ensure proper coating quality. Part of the enamel is absorbed into the rust, and solid components remain on the surface. Achieving a good protective film will not work.

- Dry spray. This method is suitable if an experienced specialist will perform the work, and the equipment will be specially configured. Otherwise, the adhesion and resistance of the coating will decrease.

- Use of unsuitable solvent. You can use only those tools that are indicated in the instructions and are compatible. Other solvents will violate the properties of enamel, will dry for a long time. White spirit can not be used for primers!

- Early use of the product. After completing the coating, you should wait for the complete polymerization as the solvent dries and the primer itself. The quality of the film will otherwise be impaired.

- Application on a smooth surface. To ensure good adhesion (adhesion), the surface should be rough, but free of contamination. Enamel is specially designed for surfaces with rust. Smooth materials should be pre-treated by roughening.

Compliance with all the tips and the implementation of staining strictly according to the instructions will allow for a long time to preserve the integrity of the products, protect them from corrosion.

Enamel Description

Universal primer-enamel XB-0278 is a special type of primer, which additionally has the characteristics of an enamel, in addition, it converts rust. This tool combines these three functions at the same time. Primer enamel is not a novelty that the market offers; this material has been manufactured for more than 15 years by Antikor-LKM.

The primer is packaged in containers from 1 to 25 liters, the cost of one liter of enamel is 120 rubles. The operational life of the XB-0278 primer-enamel is about 5 years, subject to the rules for surface preparation and painting. If necessary, you can buy modern paints and varnishes, whose service life is up to 15 years, but the price of such compounds is much higher. Now the manufacturer produces a primer XB-0278 of various colors, you can choose one of the following shades:

- blue,

- yellow,

- blue,

- brown,

- grey,

- the black.

Areas of use

Enamel primer is used in various fields, including the following areas:

- processing of any metal structures at industrial facilities and in domestic conditions,

- painting of units, installations and machines that are exposed to gases, water vapor, aggressive chemical compounds, reagents, water heated to a temperature of 60 degrees,

- application to rust and corrosion, the depth of which is not more than 100 microns,

- painting of parts and structures made of cast iron, steel, iron, even in those places where there are areas of soot or scale,

- painting of various designs with large dimensions and complex shapes, for example, automobile parts, metal garages, gratings, stairs, fences, gates,

- primer can be applied to those structures that do not need decorative design,

- base treatment for creating a refractory layer.

In addition to applying to metal structures, XB-0278 is suitable for processing concrete products and reinforced concrete structures, for example, curbs, fences, or walls.

Enamel Composition

The main chemical ingredient in primer-enamel is perchlorovinyl resin, as well as several additional components. This resin is often used in the manufacture of bathtubs and pipes, often in contact with aggressive chemicals, as well as perchlorovinyl substance is used to produce various paints and varnishes with protective properties against rust and corrosion. In addition to this resin, the composition includes:

- alkyd and epoxy resin

- coloring pigments, to give the enamel the necessary shade,

- plasticizing agents

- chemical rust converters,

- substances that prevent corrosion and metal oxidation (inhibitors).

Specifications

Enamel XB-0278 is made in accordance with GOST, which prescribes all the technical characteristics and composition of this paint material. Each batch is accompanied by an official certificate confirming the high quality of products. The certificate indicates the specific properties of the primer, as well as the characteristics of the enamel after its application. Here are the main technical characteristics of the XB-0278 primer-enamel:

- the viscosity index, according to the VZ-246 viscometer or similar device with a nozzle diameter of 4 millimeters at room temperature, is 30 s for black enamel, and for all other shades the viscosity is at least 40 s,

- the volume of non-volatile components for black paint is from 34 to 44%, for all other shades of the primer from 30 to 36%,

- the drying period of the soil-enamel to the third degree is about one hour at a temperature of 20-22 degrees,

- consumption per square meter is 120-150 grams. The flow rate depends on the thickness of the rust, the method of application and the characteristics of the processed material,

- the thickness of a single-layer enamel coating is from 20 to 25 microns (first layer), from 20 to 40 microns (second and third layer),

- the recommended number of applied layers on the surface is 2-3,

- the milling index is not more than 40 microns,

- bending elasticity of the dried layer - maximum 1 millimeter,

- adhesion index is 1-2 points,

- hardness, according to the pendulum device, not less than 0.15 units,

- resistance to the effects of 3% sodium chloride - at least 72 hours at room temperature,

- the coefficient of conversion efficiency of the rust layer is from 0.7.

After applying the enamel, a matte, uniform, dense layer is formed on the surface, without extraneous elements.

Foundation preparation

It is necessary to apply a primer on a well-prepared surface on which rust may be present. If there is loose rust, it must be treated with a wire brush to separate. It is important to remove from the base the remains of old paints and varnishes, as well as any dirt, such as dust, dirt, scale, grease stains, using a solvent.

Enamel storage rules

In order for the primed coating to be as high quality and durable as possible, it is necessary to know and follow the rules for storing the paintwork material. It can be transported in any way, the temperature should be a maximum of 30 degrees.

During transportation and storage, it is necessary to protect the container with enamel from the effects of precipitation. Do not allow the container to be stored next to heating appliances or in a room with high humidity. The room should be darkened by sunlight, and the container with enamel must be tightly closed.

It is allowed to store the composition even in frost, at a temperature of -25 to +30 degrees. Observing these rules, the composition will not lose its characteristics for a long time. The shelf life of enamel is one year from the date of production.

Dilution of a primer

If the composition is too thick, it can be diluted, for this, solvents R-4 and R-4A are used. These solvents can be used to pretreat, clean the base from contamination. Also for dilution, you can use the compositions of R-670 and R-670A.

The manufacturer does not indicate how much solvent can be added; the viscosity of the mixture can be checked during application. If the enamel is applied with a brush or roller, it may be more viscous than during spraying from a spray gun. During dilution, it is necessary to add the solvent in small portions, after each of them it is important to mix thoroughly. When the composition is applied to the base, the solvent will quickly evaporate, and the film will become strong after drying.

Important! Any solvent is toxic and harmful to humans, so when working with soil-enamel diluted with a solvent, wear a respirator, rubber gloves and thick protective clothing. When working indoors, it is important to arrange for proper ventilation or ventilation.

Staining rules

Apply XB-0278 is allowed by any of the following methods:

- with a brush

- roller

- spraying from a spray gun, spray gun,

- dipping (suitable for small parts).

During the application of the primer, the temperature should be in the range of -10 ... + 30 degrees, and the air humidity of 55-80 percent. The first applied layer dries in about 1-2 hours at room temperature, all subsequent layers can be applied one hour after applying the previous coating. To make the film durable and strong, it is recommended to apply two to three layers. When applying the first layer, rust is transformed, the second coating is anticorrosive, and the third is decorative.

Common mistakes

During the use of primer-enamel, the following erroneous actions must be avoided:

- Do not apply only one coat. Sometimes to save the solution, some process metal structures with only one layer. Such a coating is not high quality, since the primer is simply absorbed into corrosion or rust. Apply the composition with two to three layers in accordance with the instructions,

- Do not use dry spray. This method is only suitable when a qualified technician is working with properly configured equipment. If the beginner will paint using the method of dry spraying, then the adhesion and stability of the protective layer will be minimal.

- use the wrong solvent for dilution. Only those solvents that are indicated in the instructions may be used. All other compounds will violate the characteristics of the enamel, it will dry out for too long. It is forbidden to mix the primer with white spirit,

- it is impossible to operate products ahead of time. It is important to wait until the painted coating cures completely, otherwise the quality of the protective layer will be reduced,

- Do not apply XB-0278 on smooth parts. In order for the adhesion index to be sufficient, the base should not be smooth, but rough. The primer is made specifically for application on rusty, uneven substrates. If the base is smooth, it can first be treated with sandpaper, roughened, and only then painted.

By following these recommendations and applying the enamel strictly in accordance with the instructions, the metal part or structure will be reliably protected.

Where to buy XB-0278?

9 companies are ready to supply XB-0278

from 100 ₽ / kg to 200 ₽ / kg

the price depends on the volume, delivery time, color and packaging

Fill out the application right now and receive offers on XB-0278 or similar materials.

Do painting work?

Fill out the form and visitors to the Corrosio.ru portal will find out about your company.

Application

HV-0278 primer-enamel is intended for painting steel and cast-iron structures with residues of scale and tightly adhering rust (thickness of corrosion products up to 70 μm), exposed to industrial atmosphere containing aggressive gases and vapors, as well as to salts and other chemical agents having temperature not higher than 60ºС.

Recommendations for use

Before painting, the steel surface is cleaned of the old, loose coating, loose rust and scale, dirt, oils, then dust is removed and degreased with solvent R-4 or R-4A.

XB-0278 primer-enamel is applied to the surface:

- when used as an independent coating in 3 layers, in a complex coating - in 2 layers and overlap with enamel,

- when painting a metal surface covered with tightly held rust, it is recommended to apply the first (developing) layer of soil-enamel with a thickness of not more than 10-15 microns to improve adhesion,

- The thickness of each subsequent coating layer is 28-32 microns. The total thickness of the three-layer coating is 70-80 microns.

Primer-enamel is applied at ambient temperature from -10 to + 35 ° С.

Preparation of coatings before use

Before use, the XB-0278 primer-enamel is thoroughly mixed.

- When applied by brush, roller, airless spraying and dipping, dilution of the enamel is not required,

- When applied by pneumatic spraying, the XB-0278 primer-enamel is diluted to a viscosity suitable for working with solvent R-4 or R-4A.