Today, little is so much appreciated in a house as its cosiness and the ability to provide comfortable conditions for yourself and your loved ones. One of the most popular ways to solve this problem today is to install an electric heated floor, which is better than a cable, mats or infrared film in this case is fundamentally important. The choice can be made based on the characteristics of each type of equipment, its capabilities and technical characteristics.

Types of cable underfloor heating

The popularity of electrical systems is mainly based on features such as

- ease of installation

- ease of use

- durability,

- affordability

- the ability to quickly adjust the temperature.

In addition, in many cases, the use of similar equipment connected to a heating system or hot water supply is associated with many problems, beginning with the need to dismantle the floor, form screed, lay pipes and ending with the need to obtain special permission for such an installation (for apartment buildings with a central water supply) .

For most apartments, the only possible solution is to install an electrical system.

Therefore, when choosing equipment, the question arises as to which film or cable floor heating is better. In the first case, it is supposed to use a flexible film, which is an infrared heating element, in which carbon strips are located, interconnected by copper buses to supply power voltage.

Its advantage is the ability to avoid additional screed and lay the film directly under the floor without any difficulties in the installation. But at the same time, it is also worth highlighting such features of infrared systems as the need for a perfectly flat surface for laying in order to avoid damage to the film. In addition, the average life of infrared heating materials is 5-10 years.

If you plan to install a cable underfloor heating, the characteristics of the equipment are determined primarily by the heating power, depending on the area of the room, its purpose. In addition, it is important how the equipment will be used: as the main or additional heating.

The effectiveness of the underfloor heating, the technology of its installation largely depends on the type of flooring used.

The principle of operation of cable underfloor heating is based on the use of a heating cable (or mat) as a heat source. It is placed under a cement-sand screed. Then the flooring is laid. As a result, a solid heating surface is formed, which has sufficiently high energy efficiency indicators.

Resistive cables

This type of heating elements is especially popular due to its affordable cost in comparison with analogues. The conductor can be presented in one - or two-wire execution. The principle of operation of the heating cable of the warm floor is no different from the standard heating element: in this case we are talking about an elongated heater enclosed in a protective shield. Provided it is connected to the power grid, it will generate a certain amount of thermal energy.

One of the key features of all resistive cables is that they have a fixed length that cannot be changed. A common mistake is trying to shorten the wire for a warm floor, its characteristics change radically: the cable resistance decreases, and the current increases so much that it simply fails.

Newsletter subscription

Currently, the warm floor from the category of exotics has moved into the standard way to provide comfort and warmth in cold periods. Electric heating is carried out using a special cable laid by the snake in the screed, as well as a regulator that maintains the required temperature. The cable for the warm floor has a direct impact on the reliability and functionality of the entire system, so you need to seriously approach its choice before buying and installing.

There are two types of heating cable for underfloor heating: resistive - this is a cable with constant power, as well as self-regulating, whose power varies depending on the temperature of its environment.

A resistive cable for a warm floor is an element with constant parameters: core resistance, power (17–22 W / m) and length. There are single-core and two-core resistive cables. The first are cheaper and are often used to heat the roof, steps and industrial facilities, as well as residential premises. The second ones are more convenient to install, since there is no need to return the second end of the heating section.

Depending on the area of the heated surface, you can choose a different length of the heating cable. For domestic premises, as a rule, cables are selected at the rate of 100–140 W / m². In order to choose the right cable, you must calculate its length. For this, the formula is used: power consumption per square meter (W / m2) / cable power (17–22 W / m) * heating area (m2). When calculating, the floor area not covered by furniture or household appliances that are installed directly on the floor should be taken into account. Suppose you want to make a heated floor in a bathroom with a surface material of ceramic tile with an area of 6 m2. For this, it is necessary that the power be approximately 120 W / m2, in which case the total power will be 680 W. If the cable has a power of 20 W / m, then the cable length will be 34 m (or the closest).

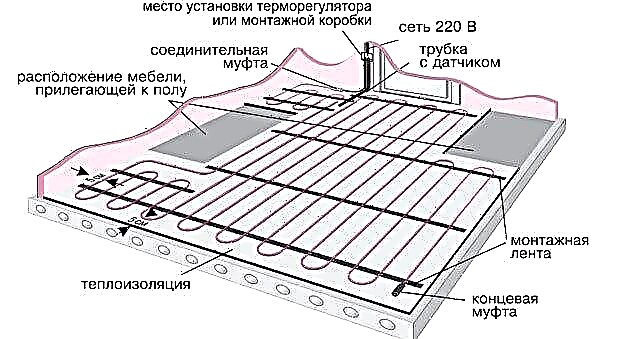

Figure 1. Connection diagram for a 1- and 2-core heating cable The “hot” end is a heating cable for a warm floor, which is placed in a cement screed with a connection sleeve, while the “cold” end, that is, a power cable, is connected to the thermostat which controls the heating.

The heating section of the cable is laid with a snake in increments of 8–12 cm, and the electric cable (“cold” end) is led out to the thermostat. A temperature sensor is also displayed on the thermostat, which is installed between the turns of the heating cable in the screed. The temperature controller provides voltage to the heating section, depending on the readings received from the temperature sensor. Thus, if the floor is heated, the sensor gives a signal and the thermostat stops supplying voltage, and when the floor cools down, the thermostat turns on.

The price of this type of underfloor heating cable is relatively low, so the demand for these products is quite high. Currently, there are a large number of companies that manufacture these products, for example, the Danish company Devi, the Swedish Thermo, the Norwegian Nexans, the Spanish CEILHIT, the German Stiebel Eltron, the Finnish Ensto, as well as the Russian CCT and budget options of the Chinese company Thermopads.

However, a “cheap” version of a warm floor using a resistive cable can cause some inconvenience. For example, in the room in which the resistive heating cable was mounted, you can not rearrange the furniture, as well as to lay mats on the floor or move them. Despite the fact that for underfloor heating systems based on a resistive cable, it is indicated that the temperature is controlled by a regulator, in reality it is monitored over a small area. Due to this, in places where furniture is located or a dense carpet lies, the heat transfer of the cable is deteriorated, which can lead to overheating.

If the area of the floor where the temperature sensor is located is covered with a carpet, the correct operation of the system is simply impossible, which generally significantly reduces the reliability of the floor heating system. Another factor that affects the reliability of the system is the quality of the sleeve with which the “hot” and “cold” ends of the cable are connected.

The heating cable for the underfloor heating periodically changes the temperature, while the power cable connected to the controller keeps the temperature constant. A change in temperature leads to “stress” in the coupling, which may ultimately lead to failure of the entire system.

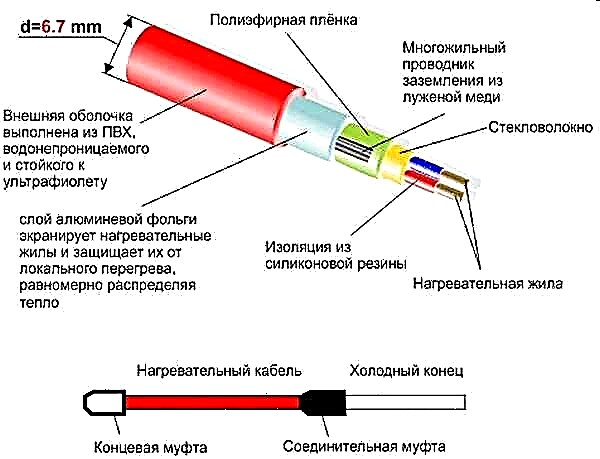

Figure 2. Design features of a self-regulating cable A self-regulating cable for a warm floor has significant differences from a resistive analog. The cable design includes two conductive wires located parallel to each other, a heating element - a semiconductor matrix, as well as a steel braid and an outer sheath of polyolefin.

The design of this cable provides different heat dissipation on different cable sections. Thanks to the special design, the heating cable for the underfloor heating independently changes the temperature in accordance with the dynamics of temperature changes in the room. Self-regulating cables take into account the ambient temperature in each individual section, which allows you to enable or disable different sections of the heating.

The cost of a self-regulating cable is higher than that of a resistive cable, however, its reliability indicators also significantly exceed the indicators of a resistive cable. Installation of a self-regulating cable is carried out similarly to a resistive one, however, in the case of the first, there is no need to install a thermostat.

Which cable is better to choose for installing a warm floor?

Currently, self-regulating cables for installing underfloor heating are supplied by Thermon and Raychem from the USA, Ensto, CCT, etc. Cables from these companies provide up to 20 years of operation without any damage. Repairing a warm floor cable can cost a lot of money, so you should not save by purchasing a cheaper cable - it is better to buy a more expensive and high-quality cable than then spend time and money on repairs.

As for the cost, laying the cable of the heat-insulated floor of the resistive version necessarily includes the installation of a regulator, which also costs money. The self-regulating cable does not need additional temperature control, since it itself reduces and increases heat generation. In small areas, such as in the bathroom or toilet, the regulator is practically not used. In addition, such a cable is divided into segments of any length, so that you can choose the optimal length and not spend a lot of money.

Figure 3. Ways of laying the cable in the toilet However, if the heating area increases, the situation changes: in this case, it is more economical to use a resistive cable. For example, in the kitchen the furniture is stationary and does not require rearrangement, the table and chairs do not have a large area of contact with the heated surface, that is, good conditions are created for the resistance cable to work.

In the case of a hall or a corridor, it is better to choose a self-regulating option, since carpets and rugs, which are often placed in these rooms, can create adverse conditions that worsen the heat transfer of the resistive cable.

Thus, the feasibility of using one or another type depends on which room the heating cable will be laid.

Underfloor heating: choosing the right cable

Electric floor - an additional source of heat in the apartment or an element of heating in the house.

Electric floor - an additional source of heat in the apartment or an element of heating in the house.

It will become the key to comfort, because how pleasant it is to walk barefoot on the warm floor.

The main advantages in favor of choosing such a system are efficiency, as well as ease of installation.

Before proceeding with installation work, it is necessary to select a cable model. The efficiency of the system directly depends on this element.

The advantage of underfloor heating

- Does not take up additional space, which allows you to implement design ideas.

- Guaranteed no drafts in the house. The heat rises evenly by 2-2.5 meters, which is ideal for heating the apartment.

- Electric models are equipped with a heat regulator, which allows you to control the temperature regime according to outdoor temperature.

- The air does not dry out, the optimum humidity of the room is maintained.

- Compared to traditional heaters, the room warms up faster.

- Heating systems are hidden from prying eyes, which does not spoil the external style of the room.

Which cable is best to choose for underfloor heating: characteristics

When choosing it is important to consider the following nuances:

When choosing it is important to consider the following nuances:

- The price of the product should not be very low, because such a cable can quickly fail. Therefore, it is better not to skimp, but to take a trusted manufacturer that will last longer.

- Consider the cost of installation. The resistive option requires additional investment in the purchase of a temperature controller. When choosing a self-regulatory option, the purchase of such a regulator is not required. For a large room, it is recommended to select a resistive type wire. If in the future the mat will spread on the floor, then it is worth purchasing a self-regulating wire to prevent local overheating.

- To decide on a cable for a warm floor, it is worth considering the functionality that will be assigned to it. For direct-acting heating, a two-core or single-core cable or a thermal mat is suitable. Before installing the flooring, such products are laid in a thin layer of screed. This approach allows you to warm the room in a short time. If the function is to accumulate heat, then it is worth using a self-regulating or two-wire resistive cable. In this case, the system can cope with the heating of concrete with a thickness of 5 cm or more.

When choosing a cable, it is important to take into account many nuances, because this is the only way to achieve high-quality system operation.

Two-core

One core is used to generate heat, the second - to provide electric current. The installation process does not require the installation of two ends of the cable at one point. The two-core model has a returnable core, an additional insulation coating, which guarantees safety during cable operation.

One core is used to generate heat, the second - to provide electric current. The installation process does not require the installation of two ends of the cable at one point. The two-core model has a returnable core, an additional insulation coating, which guarantees safety during cable operation.

What section of wire do you need

The maximum current rating for thermostats is 16 A, and the load is 3.5 kW. If the floor is connected to one thermostat and the total system power does not exceed 3.5 kW, then a PVZ with a cross section of 1.5 mm2 is suitable for operation. If this indicator is greater, then it is worth paying attention to models with a large cross section. So a model with a cross section of 2.5 mm2 can withstand a load of 25A.

If you still find it difficult to choose a section, it is recommended to pay attention to the table data.

Do-it-yourself wire laying in screed under underfloor heating

Installation of the heating cable is carried out in several stages:

- A cement-sand screed is poured with a thickness of at least 3 cm. To lay a wire that will pass to the temperature regulator, it is necessary to grind a channel with a diameter of 2 cm.

- Installing a heat-reflecting layer of the substrate.

- Installation of reinforcing mesh, on which the cable is fixed. If you do not use a grid, then you have to install the tape. The product should not be laid under furniture.

- The wire is laid.

- The heat dissipator is installed in a special corrugated tube and is placed in a strob.

- A cement screed with a thickness of 4 cm is poured. Ohmic resistance and insulation resistance are indicators that should be set to determine the operability of the cable after pouring.Laying the flooring is carried out after the solution has completely dried, which will happen no earlier than a month.

When carrying out installation work, it is important to follow these installation rules:

When carrying out installation work, it is important to follow these installation rules:

- Do not allow loops in the cable. Separate sections should not intersect.

- According to safety rules, the location of heating systems from metal structures should be at a distance of 5 cm, from wood - 3 cm, but for other heat sources -50 cm.

- Follow the installation step, focusing on 6-10 outer diameters of the wire.

- The hot part of the wire must be in the insulating material.

- When laying inside the screed, the cable pitch is 20 cm, when arranging a direct-acting floor - 10 cm.

- The batteries are not connected directly to the mains; a regulator is used for this.

- The temperature regulator is installed at 50-150 cm from the floor.

- It is forbidden to use twists, connections only through special terminals.

- To avoid power surges, it is necessary to use circuit breakers.

Prior to installation work, anyone can study the submitted videos on this topic on the network.

Choose a cable or mat

A cable consists of one or more cores with insulation and an outer sheath. Installation of such a wire will be carried out in a screed, the thickness of which is 3-5 cm.

It is recommended to install the cable under:

ceramic tiles, granite, natural stone, self-leveling floor, laminate, parquet board, pvc tile, linoleum, carpet.

Such a floor can be called almost universal.

Mats on the market are of two types - convection and infrared. Such a cable is thinner and fixed at the correct distance on the mesh base. Mats take up less space, less screed thickness up to 5-10 mm is required. Installation is simple and does not increase the planned height.

Simple installation often determines the choice in favor of the mat. The film is laid lengthwise on a thin layer of thermal insulation, and a floor covering is installed on top. Unlike the first option, you don’t have to do a screed and pour cement on the floor. This approach allows the use of mats on a vertical surface. Having appreciated the advantages of the materials presented, many prefer the latter. Such economy and ease of installation attracts many users, therefore, the popularity of mate floors is growing every day. It’s worth watching the video once to learn the editing technology.

Simple installation often determines the choice in favor of the mat. The film is laid lengthwise on a thin layer of thermal insulation, and a floor covering is installed on top. Unlike the first option, you don’t have to do a screed and pour cement on the floor. This approach allows the use of mats on a vertical surface. Having appreciated the advantages of the materials presented, many prefer the latter. Such economy and ease of installation attracts many users, therefore, the popularity of mate floors is growing every day. It’s worth watching the video once to learn the editing technology.

Warm floor - the key to comfort for residents of the house. It can be an auxiliary element of the heating system or replace it. The main advantage is ease of installation and significant resource savings. Just to ensure that the system functions correctly, you have to choose the right cable. The selection criteria are very diverse - from the cross section to the estimated load. Be sure to decide on the functionality to be laid on the warm floor. Then the cable selection process can be greatly facilitated.

Underfloor heating can be done by your own efforts using simple panels that are installed even without cement pouring. It is worthwhile to carry out installation procedures to assess the benefits of underfloor heating in action.

The choice of cable underfloor heating: one and two-core version

Depending on the number of cores, current can propagate along one or two conductors. Depending on this parameter, the connection diagram will change.

Structurally, a single-core or two-core underfloor heating are quite similar: there are conductors in insulation, as well as a protective metal braid that provides a sufficiently high level of rigidity in the layer of external insulation. Some manufacturers offer products with drainage cores, which can significantly reduce the intensity of electromagnetic fields.

In order to decide which cable is better for a warm floor, it is worth taking into account the fact that two-wire conductors are more popular despite the fact that they cost a little more. There are several reasons for this: they

- easier to install (to connect them, the second end must not be connected to the thermostat),

- generate electromagnetic fields of lower power due to partial compensation by each other for each of the conductors and the multidirectional movement of electrons.

How the heating cable of a self-regulating type warm floor is arranged

The specific design of this type of cable allows you to initially solve the problem of overheating of conductors. They are series-connected small heating elements - conductive conductors placed in a polymer matrix. The heat released in the end is precisely the polymer, when heated which increases the resistance. In this case, the current load decreases, as a result of which the volume of heat generated by the cable decreases. The only drawback of this type of cable for a warm floor is its cost, which is on average several times higher in comparison with resistive elements.

Film, cable or core heat-insulated floor: what to choose

The choice of a heating cable for a warm floor is based on such operating parameters as profitability, ease of use, efficiency and cost of implementing such a project. In each of these cases, the system is based on the use of heating wires that are able to convert electrical energy into heat. In this case, the thermostat will be able to regulate the amount of heat generated, providing a comfortable environment for the user.

Cable floor heating: mats or wire

The choice of cable for underfloor heating is based on several basic advantages of such systems:

- the service life of the wires is significantly higher compared to water systems,

- economy in energy consumption: such equipment consumes no more than ordinary household appliances,

- the cost of the project varies in a fairly wide range depending on the components selected and how they are connected.

At the same time, the disadvantages of this option are the presence of electromagnetic radiation, which accompanies the operation of any electrical equipment.

You also have to decide what is best for a warm floor mats or cable. In the first case, finished products are offered, which are produced in the factory. In this case, the heating cable is fixed on a polymer mesh basis with a certain step exposure. Their use can significantly accelerate the installation process.

That is why mats are used most often, the use of cables is recommended in several situations. The dimensions of the room may not be a multiple of the width of the mat. In this situation, there are several ways to do this: choosing between a floor made of mats or cables, you can use the first option, leaving part of the surface unheated or the second for complete heating. It is also possible that there is a non-standard layout. In this case, a lot depends on the particular geometry of the room, but with its complex configuration it makes sense to use cables as the best option.

Features

Electric underfloor heating is a modern type of heating system for residential premises. This design consists of heating mats and special controls laid under the floor or between the layers of the concrete screed.

The advantages of the scheme include:

- uniform distribution of heat along the height of the building,

- the absence of disturbances in circulation in the form of convection flows - the movement of heat in air,

- simplicity and clarity of self-installation of the system,

- budgeting of a professional installation,

- saving of useful area of heated space,

- lack of need for additional equipment,

- the ability to install under any floor covering,

- increased comfort and convenience

- environmental friendliness

- the possibility of use by people suffering from various types of allergies, bronchial asthma.

The disadvantages of electric heating are:

- high cost of 1 kW of electricity,

- creation of an electromagnetic field in the framework of a heated room,

- mandatory skills in handling temperature controllers,

- the complexity of diagnosing and repairing the system,

- the existence of height restrictions for heated buildings,

- the need for increased electrical safety through grounding.

However, with the rational design of the project and proper installation, all these shortcomings are eliminated by themselves, therefore this system is becoming increasingly popular among consumers.

The main active element of an electric heated floor is a heating cable. The effectiveness of the functioning of the entire heating mechanism depends on its quality and features, so you should carefully and responsibly choose a heating cable for these purposes.

Before making the final choice, you need to familiarize yourself with all varieties of heating cable. The following types are available.

Resistive cable

It creates the same temperature in its length and is divided into varieties:

- Single core. This species lives up to its name. It consists of one heating core, reinforced with a sheath of wire or foil. The process of connecting such a cable requires the convergence of both ends in one place, that is, connecting them to the temperature controller. A single-core cable has several advantages, namely:

- maximum heating temperature

- low energy consumption

- affordable price.

- Two-core. It consists, respectively, of two cores, which are also surrounded by a protective film. To connect a two-core cable, no return is required. The circuit is closed by connecting a special coupling to the free end of the wire. Its benefits include:

- ease of installation

- the possibility of forming tracks of any shape and length,

- one way connection

- the immutability of the electromagnetic field.

Self-adjusting

At the heart of such a cable are two conductive conductors in contact with a polymer matrix of a semiconductor, which regulates the heating of the system depending on the temperature of the surrounding space. The matrix is isolated in two layers and protected by a screen braid located between the layers. The advantages of a self-regulating wire are as follows:

- universality

- durability,

- the ability to independently select the temperature in the room,

- damage resistance

- reliability.

Electric mats

To make installation of a warm floor easier and more convenient, as well as to minimize financial costs, it is recommended to use special heating electric mats. In turn, they are divided into:

Let's consider each view in more detail:

- Cable (wire) mat Is a flat flexible device consisting of a single-core wire attached to a snake-shaped metal mesh. These mats are ideal for tiled and tiled finishes.

- Carbon or Carbon Fiber Mat It is a structure of parallel-mounted self-contained self-regulating heating rods that emit infrared radiation, which is the source of heat in such schemes.

- Film mat, in fact, is arranged in the same way as carbon.

The only difference is that the carbon rods are further protected by a polymer film.

Core floor heating

The basis of the design in this case is carbon rods, which are electrically connected to each other and connected to a thermostat. This heating system is called intellectual: it is able to independently regulate its work.

An important feature of their use is that it is possible to install (rearrange) furniture in accordance with their own tastes and desires, while eliminating the risk of overheating of elements, their burning out. In addition, there is the possibility of installing a core heated floor in rooms with high humidity. A characteristic disadvantage is the high cost, which has led to the appearance on the market of a large volume of counterfeit products.

Cable for underfloor heating under concrete screed - brand overview

Cable BNO 2x0.3 - resistive cable for underfloor heating. Used for heating floors, walls, ceilings in residential premises. Lay under a concrete screed. The operating temperature of this cable is 100 C. It works with a working alternating voltage of 220/380 V. The heat dissipation of the cable for a warm floor is 15-25 W / m.

Cable НО-3, НО-13, НО-23 - Resistive heating cables for underfloor heating with galvanized steel or copper core (alloy possible). Lay under a concrete screed. The working temperature of this cable is 100 C. It works with a working alternating voltage of 220/380 V. The heat dissipation of the cable for a warm floor is 15-20 W / m.

NBMK cable armored resistive cable, most often used as a cable for underfloor heating for a large area (trading floors). The cable is resistant to mechanical stress, corrosion, flexible. Operating temperature - up to + 90 C. It works with a working alternating voltage of 220-240 V. The heat dissipation of the cable for a warm floor is 20-25 W / m.

Resistive cables KNMPEV, KNNPEV, KNNmPEV, KNNsPEV (Chuvashkabel) is used for heating building structures and residential premises. The cable consists of 2 parallel conductors in polyethylene insulation, a shield and a PVC sheath.

Below is a comparative table of cable characteristics for underfloor heating.

| Cable brand | Poppy. section length | Operating voltage, V | Heat dissipation, W / m | Temperature, C | |||

| 220-240 | 380 | Max. working | Max. without heat. | Min mounting | |||

| BUT | 125 | x | about | 15-20 | 100 | 100 | -10 |

| NLS | 100 | x | about | 15-25 | 100 | 100 | -10 |

| NBMK | 550 | x | about | 25 | 90 | 90 | -20 |

As a cable for a warm floor, you can use imported analogues: TXLP / 1, TXLP / 2R (manufactured by NEXANS), HC-800 (manufactured by Aeg)

Cable calculation for underfloor heating

To buy a cable for a warm floor of the required meter, be sure to calculate the power of the system. For this, it is necessary to measure the area of the room (m2) minus the area of furniture under which the cable will not fit (Fig. 1). The resulting value must be multiplied by the power of the warm floor per 1 m2 for this room. Calculation of the power of the system must be made sure to avoid overheating of the cable for the warm floor. The capacities of the heated floor per 1 m2 for different types of rooms are presented in table 1.

Table 1. Power underfloor heating per 1 m2

Example: It is necessary to make a warm floor in the living room with a useful area of 8m2. The power of the heated floor per 1 m2 for the living room is 150 W / m2. The power of the entire system will be 8 m2 * 150 W / m2 = 1200 W.

Based on the capacity of the system, sellers in the store will be able to choose the cable of the desired length.

To calculate the cable length for a warm floor, you can use the formula yourself:

- L- cable length in meters

- S - heated area, m2

- Ps - required specific power, W / m2

- PL-specific power cable, W / m

Example: It is necessary to make a warm floor in the living room with a useful area of 8 m2 with the required specific power of the room 150 W / m2. For installation, a cable is used for the BNO floor heating with a specific power of 25 W / m. Thus, the cable length is L = 8 * 150/25 = 48 m.

Next, you need to calculate the step of laying the cable in the room. This is done using a simple formula:

H (laying step) = S / L, so in our example we get H = 8/48 = 0.16 m, that is, every 16 cm.

If you want to learn more about how to lay a cable for a warm floor, we recommend watching the video

Heated floor film or cable, which is better

If you compare which floor is better than infrared or cable, it is worth paying attention to the fact that with the correct installation of both systems, uniform heating, efficiency will be ensured. The rate of heating of the flooring in film materials will be significantly higher due to the absence of a screed that runs on top of the heater. But at the same time, such a system will cool down much faster for the same reason.

Both systems are reliable enough, but there is a likelihood of mechanical damage from sharp objects of the film if linoleum is used as a floor covering. On the other hand, only infrared film material can be laid on inclined or vertical surfaces.