Replacing a sink in the kitchen, installing a faucet, bathtub, door and window frames is not complete without the use of sealants. These are special compositions based on polymers that can reliably fill gaps, cracks and voids, isolating them from external negative effects. Since there are a lot of areas of use of such substances, formulations have been developed that are optimally suited to particular conditions. Before going to the store and buying, it does not hurt to decide which sealant to choose, and what types of sealants generally exist. So you protect yourself from the advice of consultants that is not always correct and beneficial for you.

No. 1. Types of sealants

Sealants are a whole group of materials, which are polymer-based compounds, have a paste-like, viscous-flowing or tape consistency and are designed to protect and waterproof joints. The remaining properties are highly dependent on composition. Sealants are used to seal joints between plumbing products and the wall, when installing windows and doors, to seal cracks between logs, concrete and reinforced concrete structures - and this is far from all areas of application.

Sealants can be divided into:

- one-component

- with two or more components.

One component formulations more convenient, as they are immediately ready for use, and sealants with several components will first require mixing all the components in the required proportions.

According to the type of hardening, sealants are divided into:

- drying formulations acquire the necessary properties only after the water or solvent has evaporated. They are characterized by significant shrinkage,

- curing compounds acquire a working state under the influence of moisture or air, or, if it is a multicomponent composition, after mixing all the components. From a pasty mass such compounds become like rubber,

- non-hardening compounds made in the form of mastics, outwardly similar to plasticine.

Most important is chemical classification:

- acrylic sealants,

- silicone sealants,

- polyurethane sealants,

- bitumen sealants,

- thiocolov.

No. 2. Acrylic sealants: properties and scope

Acrylic sealants are a mixture of acrylate polymers used mainly for internal work. They can be painted with acrylics or varnishes in any color.

Acrylic sealants are:

- non-water resistant. They are odorless, have complete environmental safety, hardly tolerate deformation, so they are best used on surfaces that are not subject to thermal expansion. It is used in the repair of furniture, window frames, as well as when working with dry walls made of drywall and concrete. Moisture on such compounds will lead to rapid damage to the sealant,

- waterproof compounds have high adhesion to almost all types of surfaces, including brick, concrete, tile, PVC and drywall. Can be used in bathrooms and kitchens, but not in pools. If the sealant will be used in the bathroom, it is desirable that the composition contains antifungal components.

All types of acrylic sealants are characteristic such benefits:

- good adhesion with brick, concrete, plaster, wood, tile and other surfaces,

- the ability to maintain initial properties in a wide temperature range (from -20 to +60 0 С),

- environmental friendliness and the absence of harmful fumes, so you can work with such sealants without personal protective equipment,

- UV resistance

- simplicity of work

- price. It costs 1.5-2 times lower than silicone sealants. The most expensive are transparent acrylic sealants.

disadvantages:

- with prolonged exposure to low temperatures, elasticity is lost,

- Acrylic sealants are inferior to their analogues in terms of moisture resistance, therefore it is better to choose other compounds for rooms with a stably increased humidity level.

Acrylic sealants, as a rule, are sold in tubes of 300-500 ml, applied directly from the tube or using a special gun. Already 15 minutes after application they form a film, and finally freeze after 24 hours.

Scope of application: filling joints and cracks in stone and concrete surfaces, boards, window and door frames, filling voids around communication pipes, sealing joints in bathrooms and kitchens, less often in bathrooms.

Number 3. Silicone Sealants

Siliconized sealants largely repeat the properties of acrylic, but due to the presence of silicone, they are more durable, flexible and resistant to temperature extremes. In addition, they are more resistant to moisture, can be used even for outdoor use.

The compositions have good adhesion to wood, plaster, particleboard, glass, can also be used to seal window and door frames. After drying, they, like acrylic sealants, can be coated with paints; oil and latex formulations are usually used.

Types of sealants for wood products

To begin with, it’s worth clarifying that the sealant is a thick, pasty mixture, which, when applied, fills all the free space. Due to this property, the treated wood surface does not absorb moisture, blocks the formation of mold and fungus, and also simply does not let cold air or water into the room.

Starting to select a suitable copy of the material for decoration, it is necessary, first of all, to determine its appearance. At present, at least four common chemical filling products are known. Let's look at each of them individually.

Acrylic Sealant for Wood

The most budgetary and easiest solution in 2019 can undoubtedly be considered an acrylic modification. It is widely distributed in stores and retail chains. Such compositions do not harm the environment and human health, and also have good adhesion and simple application. But these advantages also have a “reverse side of the coin” - low resistance to humidity and sharp changes in air temperature.

Silicone sealant for wood

The next option, which has gained considerable popularity among beginners and experienced builders, is a product based on plastic silicone. A distinctive feature of such a seal is the symbiosis of excellent hydrophobicity, durability and affordable price.

To date, two large subspecies can be distinguished:

- Acid - characterized by the presence in the composition of acetic acid, leaving a unique "aroma" on the treated tree. But the price tag is very affordable.

- Neutral - An improved version of the previous sample. Adhesion with any surfaces, no extraneous odors. But the cost is much higher - you have to pay for quality and comfort.

PHOTO: exclyzivcolor.ru Silicone sealants are used in both indoor and outdoor applications

PHOTO: exclyzivcolor.ru Silicone sealants are used in both indoor and outdoor applicationsPolyurethane sealant for wood

The most powerful and reliable composition of all is the polyurethane sealant. It is distinguished by impeccable plasticity, resistance not only to moisture, but also to mechanical stresses, as well as alkalis and salts. But note that the cost of such a product will be appropriate. And one more nuance - polyurethane is afraid of ultraviolet radiation. Therefore, for outdoor use, this modification is very limited.

Special types of sealing mixtures

Separately, it is worth highlighting sealants that have specific properties or special active ingredients. These include a sanitary seal, equipped with a number of unique additives that destroy fungi, mold and other harmful organisms. Or, for example, bitumen sealant. It consists of rubber and bitumen mixed in a certain proportion. It is ideal for insulating cracks and crevices in a wooden roof, reliable and durable. But because of the appearance, it has a number of limitations.

PHOTO: readmehouse.ru Bitumen mastic is not painted, so it is rational to use it only in the construction or repair of the roof

PHOTO: readmehouse.ru Bitumen mastic is not painted, so it is rational to use it only in the construction or repair of the roof

Scope of application

In the first place should be the type of sealant, but we discussed this in the previous section. Therefore, we proceed smoothly to the next point - the area of use. Depending on various circumstances, the following main groups can be distinguished:

| Type of sealant used | Application area |

| Acrylic | Creation of crafts and souvenirs, minor repairs in the room (temperate climate) |

| Silicone | Internal and external works (especially window openings and stairs), closing cracks in wood |

| Polyurethane | Any processing of the interior of a house or apartment, external areas of the wall that are not exposed to sunlight |

| Sanitary | Wooden parts of bathrooms, private houses near reservoirs and other conditions of high humidity |

| Bituminous | Processing of the roof and its elements |

Note! On the modern market, there are models of wood sealants based on both silicone and acrylic. They combine both the hydrophobicity and elasticity of the first component, and the favorable cost of the second substance. Having met a similar mixture in the store, you can safely take it for your needs - it is practically devoid of flaws.

Useful life

It is equally important to remember the time during which you do not need to replace the sealant layer applied to the surface of the wooden structure. As a rule, manufacturers indicate this information on the packaging with the goods, but if there is none, then you can use the table below:

| Sealant | Material service life, years | |

| Indoors | Outside | |

| Acrylic | 5-10 | 1-2 |

| Silicone | 20-25 | 3 |

| Polyurethane | 25-40 | 15 |

PHOTO: greensrub.ru Remember to remove the old layer of insulating layer before applying a new one

PHOTO: greensrub.ru Remember to remove the old layer of insulating layer before applying a new one

Temperature and humidity

Do not discount the conditions under which the hero of our review will be used. At high temperatures and insufficient humidity, increased shrinkage will be observed, entailing the formation of new gaps and the risk of a change in the position of the structure in space. In the opposite situation, the sealant may undergo structural damage and loss of original properties.

PHOTO: arkhangelsk.sazi-group.ru Non-observance of the operating rules leads to irreversible consequences requiring costly elimination

PHOTO: arkhangelsk.sazi-group.ru Non-observance of the operating rules leads to irreversible consequences requiring costly elimination

Hue

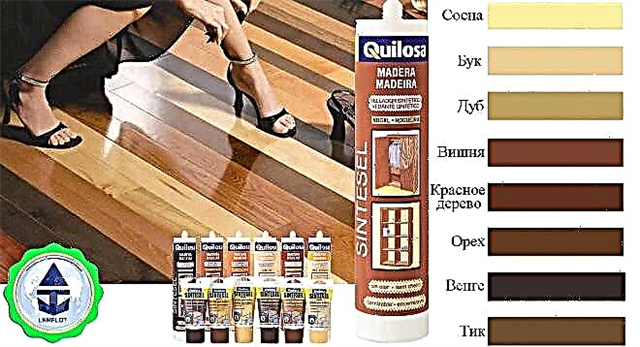

Some insulation products do not allow additional application of paint on top of the applied layer. Fortunately, manufacturers have long resolved this problem, giving their products certain shades. You just have to choose the right color before use.

PHOTO: germetikmag.ru Take a picture of the structure before going to the store and during the purchase compare the colors indicated on the package with the photo

PHOTO: germetikmag.ru Take a picture of the structure before going to the store and during the purchase compare the colors indicated on the package with the photo

The best manufacturers of products in 2019

It is also worth saying a few words about the manufacturers. There are many unknown companies producing low-quality products, albeit at competitive prices. The editors of HouseChief invite their readers to get acquainted with our rating of companies whose products, at least, do not raise doubts about their quality, reliability and popularity.

| Manufacturer | The most famous brand product | Photo |

| Olive | Accent 136 |  PHOTO: prorab.help PHOTO: prorab.help |

| Rainbow | ForWood G01 |  PHOTO: domkrasok19.ru PHOTO: domkrasok19.ru |

| Experttecology-Neochem | Neomid Wood Professional |  PHOTO: priceguard.ru PHOTO: priceguard.ru |

| Perma-Chink Systems | PermaChink |  PHOTO: dom56.ru PHOTO: dom56.ru |

| Soudal | Soudal Parquet |  PHOTO: inter-sil.ru PHOTO: inter-sil.ru |

For example, we suggest you also study the review of one of the sealants indicated on our list:

Read more on Otzovik: https://otzovik.com/review_1249919.html

Tips for applying sealant to wood correctly - step-by-step procedure

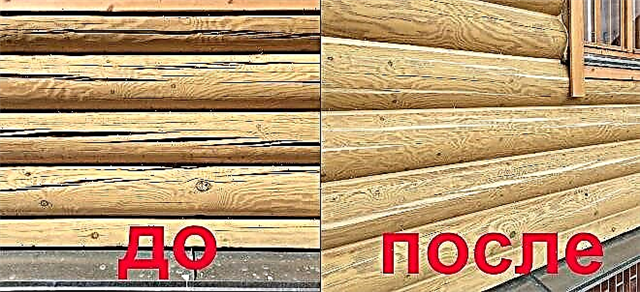

Suppose you have purchased a sealant suitable for all properties and want to test it in action. Alas, this process requires preparatory work and certain skills. For the first time, styling will not work flawlessly. But to understand the process, we recommend that you familiarize yourself with the simple step-by-step diagram of actions attached below. For example, we took interventional seams, since they are the most time-consuming and responsible.

| Illustration | Description of Actions |

| We clean the joint surface from dirt, dust and other foreign objects (if a layer of sealant or paint was previously applied, then they must be removed) |

| We take a heat-insulating cord (you can buy it in a store or make it yourself from foam rubber) and lay it along the entire length of the seam, carefully deepening inside |

| We fix the previously purchased cartridge with sealant in the mounting gun and apply the mixture to the treated wood. If the sealant is packed in a plastic bucket, then it is applied with a spatula - but it is much longer and more difficult |

| Immediately after application, we take a brush or other similar object and align the sealant layer, while removing excess residue along the edges of the logs |

| Using a piece of cloth (rags or special napkins) we remove the emerging smudges, since the composition is able to periodically increase in volume in the first few minutes |

| We repeat the same steps with corners and cuts - they are more time-consuming, but do not require any special procedures |

Note! In order to repair a crack in a log or other object using sealant on wood, in addition to cleaning the surface, you will also need to stick tape or masking tape from both edges. Further actions completely duplicate the scheme described by us earlier. Only at the final stage do you remove the adhesive tape from the “healed” wood, receiving in return an even seam.

Conclusions

So our journey into the world of insulation materials for wood came to an end. We hope that each of our readers has found a lot of useful information that will help in the construction and repair. In turn, the editors of HouseChief would be very interested to know the opinions of those of you who have already used wood sealants. Tell us in the comments about your experience. Finally, we want to wish each of you a successful construction and repair, warmth and comfort. See you soon!

PHOTO: sk.master-srubov.ru A correctly executed and painted seam will become a decorative decoration of your home

PHOTO: sk.master-srubov.ru A correctly executed and painted seam will become a decorative decoration of your home

Silicone

Silicone compounds can be divided into acidic and neutral. The first contains acetic acid, so after hardening the substance for the tree, a specific aroma appears. Acid varieties are considered universal, have an affordable price and are actively used during construction and repair work.

Silicone types are characterized by such qualities:

- Strength and durability, operation period of 20-25 years.

- Versatility - the ability to use for all types of work outdoors and indoors.

- Water repellent.

- Preservation of softness and extensibility after polymerization.

- Immunity to temperature changes and atmospheric effects.

- After curing, the sealant does not have an adhesive layer, due to which other substances do not adhere to it, and new layers of the same material do not adhere.

If you need to choose a brown sealant to match the color of the wood, you can study the wide range of varieties from different manufacturers.

Polyurethane

Types based on polyurethane for sealing wood joints are considered the most wear-resistant and reliable, but also the most expensive.

They are characterized by such qualities:

- A high degree of adhesion with almost any building base.

- Immunity and lack of deformation under mechanical influences.

- Increased elasticity.

- Completely waterproof.

- Resistance to alkali, acids.

- After hardening, they do not shrink, which facilitates preliminary calculations of the consumption of the substance.

- Ideal for sealing external joints and external joints, easy to operate.

After polymerization, polyurethane varieties for wood can be painted without problems, but such sealants cannot boast of a huge variety of colors.

Acrylic Substances

Acrylic sealant for wood is used more often than other varieties and has the following properties:

- High adhesion with porous and fibrous substrates.

- Ease of use.

- Finished hardened joints can be painted without problems.

The composition of acrylic sealants does not include toxins and solvents. Acrylic sealants for wood for outdoor use are extremely rare, as they are characterized by poor water resistance characteristics, are not able to withstand the effects of high and low temperatures. With regular contact with moisture, they lose their properties and simply peel off.

Therefore, most often, acrylic varieties are used to seal the necessary areas exclusively indoors, where humidity is minimal. There are special acrylic waterproof sealants, the basis of which are latex or silicone, they are created specifically for sealing external street cracks and crevices.

Sealing technology for interventional seams

This kind of repair and construction work is not time-consuming and complicated, but you also need to know some of the nuances and subtleties of the work. In order for the final result to be accurate and high-quality, as well as to ensure reliable insulation, which remains for a long time, you should study in detail the technique of working with the composition and the features of preparation for the procedure.

Surface preparation

It’s not necessary to somehow prepare a new log house for sealing; the main thing is that the joints should be cleaned. If the structure is not new and has long been in operation, then the foundation is prepared in this way:

- If mold, fungus is found on the surface of a tree, it is necessary to treat it with an antiseptic so that microorganisms cannot destroy the wood.

- If there are oil residues or greasy stains on the surface, they should be treated with a solvent until completely eliminated.

- If wide cracks are visible on the surface, then for a more economical consumption of the sealant, you must first fill them with insulation.

Sealant Application

First of all, you need to start processing horizontal seams and joints, and it is better to leave the zones in the corners in the end.

- With a damp cloth, wipe the joints of the treehouse to clean them of debris and dust.

- A tube is placed in the gun, the tip of which is cut off at an angle of 45 ° C. The diameter of the sealant nose should be 4-5 mm.

- The tip of the tube must be tightly pressed to the joints of the surface of wood, the gun itself should be parallel to the seam.

- The composition is gently squeezed out with a gun, the device itself moves slowly along the seam. For reliable sealing, it is enough to create seams 4-6 mm thick.

- After filling the joints along the entire length, with a narrow spatula dipped in water, the composition is smoothed. The action must be performed with minimal pressure so that the seam is not too thin and does not burst. Excess composition is removed with a brush and a clean, damp cloth.

If a color sealant was chosen for wood, then one should take into account the factor that its final color does not appear immediately, but 4-10 days after its application. It is necessary to protect the walls from moisture during the first 3-4 days after application to allow the sealant to harden completely.

Cracking

Sealing cracks with sealant is done in the same way as working with inter-crown seams. Cracks must also first be cleaned of debris and dust by any convenient method, for example, water or compressed air. After that, the surfaces adjacent to the cracks should be protected with masking tape. To seal deep cracks, a foam polyethylene sealant is placed in them.

Recommendations for the selection and use of sealant

The quality of the final sealing work depends on the right material for working with wood. It is necessary to choose sealants with the greatest elasticity, since the structures themselves are prone to deformation. For glued-beam buildings, it is better to choose standard sealants that are resistant to cracking and shrinkage. When purchasing products, it is necessary to check the expiration date, integrity of the package and its tightness.

Important! Many compositions have universal application, that is, you can work with them even in humid conditions, at low temperatures. However, you should not work with sealant outside the room during a rain or snowfall.

When operating in low temperatures, the viscosity of the composition increases, so the application process is significantly more difficult. If such conditions cannot be avoided, then before this you need to leave the sealant for a day in a warm room.

To save the composition, you can not dilute it with water or use the remnants of two different sealants, mixing them together. In most cases, after solidification, the material will begin to delaminate, and the degree of adhesion will also decrease. If the material in the container is frozen, it will not lose its properties. It must be defrosted carefully at room temperature. Do not place cylinders near a battery, open flame, or other heating equipment.

No. 6. Bituminous and rubber sealants

Bitumen sealant - this is a paste-like material made on the basis of a modified bitumen binder with the addition of special fillers that provide resistance to negative environmental factors. Rubber compositions are prepared on the basis of synthetic rubber

Bituminous and rubber sealants are indispensable when carrying out roofing worksare used for fixing roofing material and other bituminous coatings, for fixing polystyrene foam, polyurethane and other insulating materials, are also used to close cracks in the foundation and drainage system. In addition, both compounds can be used to seal joints in rooms with high humidity and even to repair rubber products.

In most properties, these two types of sealants are similar, which gives the right to talk about common the benefits:

- high elasticity

- resistance to high humidity, sun rays, mechanical damage,

- high adhesive properties, which allow not to clean the initial surface before applying a layer of sealant,

- simplicity in work.

Minuses:

- it is impossible to carry out work on applying sealant at subzero temperatures,

- Bituminous sealant cannot be painted, but rubber can be painted.

Number 7. Butyl rubber sealants

Butyl rubber sealants are obtained by copolymerization of isoprene and isobutylene. As a result, an uncured material is formed, supplied in the form of mounting tapes and gaskets of various thicknesses and widths. Such tapes are used in the installation of subroofing materials, for sealing interpanel seams, as well as in the installation of skylights.

Benefits:

- elasticity that does not lose over time,

- adhesion to concrete, metal, wood, glass, plastics,

- wide range of operating temperatures, from -45 to +150 0 С,

- the ability to repeat the deformation distortion of roofing materials.

disadvantages:

- low durability, about 5 years,

- low tensile strength.

Number 8. Thiokol Sealants

Thiokol (polysulfide) sealants are considered one of the most durable, durable and expensive formulations. Typically, such sealants consist of 2-3 components (base, curing paste and vulcanization accelerator), which are mixed in predetermined proportions before use. The resulting composition must be used within two hours, complete solidification occurs from several hours to a couple of days.

Benefits:

- high elasticity

- the highest resistance to aggressive substances, gasoline, kerosene, oils, which allows the use of sealant in the arrangement of garages, gas stations, laboratories, etc.,

- resistance to precipitation, UV rays, as well as to a wide temperature range (from -50 to +130 0 С),

- high adhesion to concrete, reinforced concrete and metal, which makes it possible to use sealant in the repair of metal roofs,

- durability.

disadvantages:

- high price,

- the need to use protective equipment when working,

- the need to perform all work on applying sealant is very quick.

No. 9. What must be considered when choosing a sealant?

Naturally, before you go to the store, you must clearly understand where and under what conditions the sealant will be used. If this is a bath, then a moisture-proof composition is necessary, if there is a wooden floor, then the sealant should be flexible and not contain solvents. Moreover, Pay attention to what is indicated on the package:

- area of application of the composition (external or internal work),

- type of work performed (roofing, window, plumbing, etc.),

- the manufacturer must indicate for which types of surfaces the sealant is intended and whether it is elastic or not,

- color composition. If the sealant cannot be painted or simply will not be painted, its color is important so that aesthetics do not suffer,

- sealants can be domestic and professional, the latter are more difficult to use,

- pay attention to the indicated operating temperatures of the composition, comparing them with the existing climate features in the region.

No. 10. Sealant manufacturers

The name of the manufacturer is a guarantee of the quality of the sealant. To be 100% sure of the high quality of the purchased composition, trust the products of large companies. Very well established sealants of such manufacturers:

- Ceresit - A true giant in the field of construction materials, part of Henkel Corporation. Among other things, it produces silicone and acrylic sealants. The highest quality

- "Moment" - One of the trademarks of the German corporation Henkel, whose plants are located in 70 countries, and products are sold in 125 countries. Under the trademark "Moment" in the domestic market are silicone, polyurethane, acrylic and bitumen sealants in a wide range

- CIKI FIX - Turkish company producing silicone sealants. Decent quality, reasonable prices,

- Belinka belles - Slovenian manufacturer specializing in the manufacture of paints and protective coatings for wood, but the range also includes silicone sealants,

- Selena - an international corporation with Polish capital. The group includes 30 companies around the world; a wide range of products is produced. Sealants are manufactured under the TYTAN trademark, specialized professional compounds, silicone, acrylic, bituminous and rubber sealants are offered,

- Krass - A group of companies whose factories are located in the Netherlands, Switzerland and Poland. Among the sealants are silicone, siliconized and acrylic compounds.

Carefully study the descriptions from the manufacturer on the packaging - it is worth spending a little time studying all the characteristics in order to avoid unnecessary expenses and unnecessary purchases or, even worse, a bad result.

Features

In stone houses there are a lot of wooden parts and assemblies that undergo shrinkage and deformation, for example, the rafter system, logs, doorways, so sealants are used in all types of buildings. The purpose of the sealant is to isolate cracks and cracks from moisture and heat loss.

This material contains many components.that give it the necessary properties: binders, plasticizers, antiseptics, dyes, polymers. By consistency, sealants are pasty, similar to thick glue. Regardless of the type, the sealing compounds for wood have the following advantages:

- ductility - the ability to fill all voids, joints, penetrate the depths of cracks,

- elasticity - the ability to withstand loads when drying wooden parts without deformation,

- adhesion - strong adhesion to wood,

- resistance to temperature jumps without changing working qualities, frost resistance,

- moisture resistance to provide waterproofing of joints and joints,

- antiseptic properties that prevent the development of rot, bacteria, harmful microflora, insects,

- long service life

- low thermal conductivity to maintain heat in the house,

- stealth, which is important for the repair of decorative wooden surfaces.

For ease of application, manufacturers packaged the sealing paste in a special construction syringe with a thin nose. The composition includes colors that imitate the shades of various types of wood, which allows you to make seams invisible. During the evaporation of the solvent, the polymerization process takes place and the sealant solidifies, acquiring the design strength.

There are several types of sealants for wood, they are divided by area of application and are for indoor or outdoor use. Universal pastes of wide application are produced, there are also mixtures specifically for windows, roofs, log cabins. By special properties, waterproofing, heat-insulating and sanitary seals can be distinguished. The composition can also distinguish several major groups.

Acrylic Sealant based on acrylic resins has high strength, resistant to temperature extremes. It is used for sealing joints in the floor, walls, ceilings, partitions, sealing windows, doors. The composition has excellent moisture resistance, which allows for wet cleaning of surfaces, and is non-waterproof. It is environmentally friendly and fire safe, affordable.

The acrylic sealant can be tinted in any color, covered with paint or varnish on top, so the colored floor and walls will have an even tone without stripes or stains. The disadvantage of this material is its low elasticity and susceptibility to deformation when exposed to significant loads.

For outdoor use, acrylic is not suitable.

Silicone sealant It is not afraid of ultraviolet radiation, frost and surface heating; it works at a temperature of -50 to +140 degrees. It withstands deformation loads and perfectly compensates them, does not allow moisture and heat to pass through. This material is universal, it is used both for internal and external works. Silicone joint seal has the longest service life - up to 40 years. Due to its high elasticity and resistance to changing conditions, this material is used as an interventional sealant.

Silicone sealant of various colors is produced, but it is impossible to apply paintwork on it. A repeated layer or spot correction additive after hardening does not stick to the first layer. Therefore, the silicone composition is applied once.

There are three types of compositions.

- acidic ones have increased strength and have a sharp acidic smell, which disappears as the material dries and polymerizes,

- neutral compounds are more environmentally friendly, but less resistant to atmospheric influences,

- sanitary sealants contain special antiseptic additives that prevent wood damage by fungus and mold.

Bitumen sealant is based on bitumen and rubber. Its waterproofing properties allow the use of this material for sealing and repairing roofs, drains, places with high humidity.

It happens only in black, not painted.

Polyurethane Composition hardens quickly and has excellent weather resistance, excellent sealing properties and adhesion. Frozen seam can be painted. It has excellent adhesion even when applied to a damp base. Polyurethane sealant is waterproofing, designed to work in high humidity and sealing for dry and hard surfaces. Such seals are produced with various indicators of hardness.

The disadvantages include the presence of a pungent odor, due to which a polyurethane compound can be used only on the street.

Color palette

The hue of the sealant is important, especially when repairing wooden coatings, when you want the place of repair to be inconspicuous. In this case, the color closest to the main one is selected. It should be noted that the sealant acquires the final color only after complete solidification. Manufacturers have developed a color scheme that imitates various species of trees, such as wenge, larch, pine, oak, rosewood, teak, walnut.

For decorative arbors, baths, children's houses and other wooden structures, the original solution is to use contrasting shades of sealant. Colored seams will give the building a spectacular and elegant look. You can choose a neutral shade, then the seams will be visible, but not much. If the desired color was not found in the finished product line, then almost any color scheme can be ordered.

Silicone sealants can not be painted, the bitumen composition can only be black, and the remaining types can be coated with varnish or paint of the desired tone from above.

How to choose?

Such a huge assortment puts the buyer before choosing the best option for a particular wooden house or apartment. Today, universal pastes are produced, the scope of which is wide enough, as well as special materials for processing specific nodes and solving more narrow technical problems.

To begin with, it is necessary to determine several factors on which the choice of a particular variety depends:

- materials whose joints need to be sealed,

- types of work, for example, sealing joints or cracks, joints of parts,

- tasks to be solved with the help of a sealant: insulation, prevention of decay, waterproofing,

- special or difficult operating conditions, climatic region of use.

Acrylic sealant would be most suitable for inter-log seams of a log house "Warm seam" or with the addition of latex and cellulose. It is applied once and withstands all loads and weather difficulties, shrinkage of the structure, protects against moisture and blowing, eliminates drafts and heat loss.

Bitumen sealant is excellent for roofing.

It forms a coating similar in properties to rubber and perfectly insulates joints and cracks in the wooden parts of the roof.

For internal work on sealing parquet cracks, floor boards, universal acrylic sealant is often used, which can be painted and washed with detergents on top, which allows wet floor cleaning and the joints are invisible.

To process the wooden elements of the bath, silicone or polyurethane sealant is recommended on the outside, and acrylic on the inside. When buying, you should carefully study the information on the packaging, instructions for applying, make sure that you have certificates and manufacturer's warranties.

How to use?

The technology for applying sealants for wood is simple and affordable. Any person without special skills can do all the work with their own hands. Work is best done in dry, warm weather, then after polymerization the seams will acquire all the necessary properties.

It is quite simple to clear a new felling from dust, having wiped with a clean rag. If the surface was impregnated with oil impregnations or has been used for a long time, it is recommended to remove the top layer of wood with a grinder or ordinary sandpaper using an abrasive-abrasive method. Logs and areas affected by fungus or mold are treated with antiseptic and fungicidal compounds, otherwise the rotting of the tree will continue and threatens with complete destruction.

Wide slots and interventional clearances are laid with foamed polyethylene. This material has replaced the sealing cord of natural materials and perfectly insulates gaps, does not absorb moisture, and saves sealant consumption.

Tube with a sealing compound is filled into the gun and the nose is cut off at an angle of about 45 degrees and a diameter of 4-5 mm. If the composition is packed in buckets, then they pick up a gun, holding it vertically. The sealant is squeezed into the mezhshutnoe gap, carefully filling the voids and cracks. Then the trowel is leveled and the seam is smoothed out.

You can apply paste and a spatula with a rounded nose to create smooth and beautiful seams.

Excess sealant must be removed prior to setting or glued in advance to the required areas with masking tape. You can even the seams with a spatula or clean them with a rag. Thus, vertical joints should also be processed.

To seal cracks, you must first clean them from debris, dirt and dust. To do this, it is best to use a knife or a narrow screwdriver, compressed air to purge. Then, both edges of the crack are sealed with masking tape, and a sealing cord is laid in depth. Then fill the gap with sealant and with a wet spatula smooth the surface of the seam. The final shade of the composition will pick up a few days after complete solidification.

Painting will make the repair site invisible.

What are specialized wood sealants

Regardless of the processing technology and the type of wood, all billets, whether it is a log, timber or board, are subject to natural shrinkage. Therefore, shrinkage is characteristic of wooden houses, as a result of which the seams between the elements diverge, the log itself cracks. In addition, wood is characterized by a change in humidity depending on the season, that is, even after the end of the main shrinkage, during the entire period of operation, the joints will somewhat “walk”. Traditionally, caulked walls using natural materials (tow, moss, jute, flax, etc.), today synthetic ones are also used, based on polymer non-woven fiber.

But to achieve tightness of the joints only with caulking is quite problematic, to a greater extent it helps to reduce heat loss. But moisture, as it penetrated from the outside, will continue to penetrate, and such drowning is mainly not an obstacle to drafts, not to mention the complexity of the process.

Sealants for wood are also called “warm seam”, since their main scope is seams, but they are also suitable for filling cracks in a log, and for other elements of wooden structures. Compounds for indoor and outdoor use and universal are available.

Although there are several varieties of sealants (acrylic, silicone, bitumen, polyurethane), only acrylic is specialized for wood. The acrylic-based sealant currently meets the specifics of wooden housing construction to the maximum extent possible. It has the highest characteristics in terms of elasticity and environmental friendliness of use, it has no smell either before curing or after. All such specialized materials, both domestic and imported, have an acrylic base.

Properties of wood sealants

Specialized sealants for wood should have a whole list of properties, since the scope of application involves tough operation.

Resistance to deformation - the seams are not static, with a change in temperature and humidity conditions, they are constantly deformed, decreasing in size in winter and increasing in summer. Accordingly, the sealant must be designed to work under conditions of tension and compression, so that it does not first break apart, and then - not squeezed out of the seam.

Large temperature range of operation - in most parts of the country it is hot in summer and frost in winter, which determines the special requirements for sealant to work in a wide temperature range, which not all universal and external sealants can withstand. The conditions of use may also vary, most products are not intended for application when the temperature drops below + 5 ° C, but there are also ones that can be used in cold weather (up to -10 ° C). This is true when the need for home insulation occurs in the winter, and waiting for spring is impractical.

Peel strength - so that the sealant simply does not fall out of the seam with the cord after the first winter, substances are added to the composition that increase vapor permeability and increase adhesion specifically to wooden substrates. Only specialized wood sealants are able to stay in joints for years without cracking or peeling.

Evaporation of water follows the path of least resistance, but there is still pressure on the adjoining area of the sealant and the wood. And if there is poor adhesion, there will be a breakdown of the sealant, even if it is micro, but during the season it will freeze / thaw due to the ingress of water and its freezing / thawing.

Vapor permeability: wood is a “breathing” material that allows steam to pass through well, moisture indicators in it constantly fluctuate, but surpluses are brought out. At first glance, it is not too important whether the sealant passes steam; it seems that the throughput of the wood itself is sufficient. In fact, it is important.

Vapor permeability is important if, by analogy, our skin breathes, so try sticking a piece of scotch tape on your hand, how much will it comb through? That is, a “silent backwater” is created for mold; small areas of wood will be of high humidity and will not dry out.

The achievement of the required values of the indicators mentioned above is carried out due to the presence of special additives, as well as their specific quantitative composition. That is why specialized sealants for wood meet the specifics of their application. And their special properties explain the differences in cost.

Durability- Considering the number of running meters that need processing even in a small house, not to mention the estates, it is natural that I want to carry out this procedure as little as possible. Therefore, the longer the service life indicated in the specifications, the better. But this should not be just the numbers on the label, but the data from the manufacturer's Technical Conditions.

The conclusion on longevity should be issued by an independent and authoritative institution with the appropriate rights and test methods. But in the mandatory certificates, the durability of the material is not indicated anywhere. Obtaining such proof of sealant service life in Russian conditions today is a voluntary business of the manufacturer. The vast majority of brands either do not indicate the service life, or indicate, referring to some internal tests, which are issued only on request.

What to look for when choosing

As already noted, a specialized sealant for wooden housing construction should be:

- as elastic as possible

- with high adhesive ability

- vapor permeable

- resistant to temperature fluctuations,

- durable.

The material corresponding to the field of application, coupled with the application technology, is a real opportunity to forget about the welded joints for the next 10-15 years, or even more.

Regarding the use of PVA foam and glue with sawdust, for closing cracks and seams: according to personal, long-term observations - do not waste time on this, this will not work. A wooden house "breathes" all its life, gaining and releasing moisture, small movements in the seams are inevitable. In this situation, only sealants "work", moreover, time-tested.

Such sealants, having the ability to work on other grounds, lose their properties that are fundamental in wooden housing construction. By virtue of which they may be deprived of some of the characteristics necessary for sealing specifically joints in a wooden house. Some are not flexible enough, others are non-vapor-permeable, others do not withstand temperature extremes, and others stick to a spatula rather than a log.

Choosing a sealant, evaluate all its properties in a complex.

When choosing a set of characteristics is important (adhesion, elasticity, strength, etc.), which determine the life of the sealant in our climate. The predominance of one indicator is not enough, since this is not a guarantee of the superiority of one remedy over others.

The manufacturer indicates all the characteristics either on the label or in the accompanying documentation. On the sites of manufacturing or selling companies, you can find the most complete information on all indicators. There should also be links to all available documents: certificates of conformity and protocols of test results, if any. Is a specialized sealant available from TU?

This is checked quite simply, for this it is necessary to ask the manufacturer for the Technical Conditions for the production of sealant, in which to look at the section "scope" or "purpose", where all the data are given.

Any method of repairing joints requires an investment of labor, time and money, but compared to other methods, a “warm joint” is less expensive both in terms of labor input and financially.

So that as long as possible the seams do not require new “injections” and do not become “gold”, it makes sense to carefully consider the choice of sealant, using not only manufacturers' data and third-party resources. Not all advertising slogans are reliable, only technical documentation is a proof of compliance of the claimed and real parameters.

On our portal there are several branches dedicated to this topic in the section of paints and varnishes, sealants and adhesives.

Read more on Otzovik: https://otzovik.com/review_1249919.html

Read more on Otzovik: https://otzovik.com/review_1249919.html