Recently, natural wood is widely used for exterior and interior decoration of houses, arbors, baths and other private buildings. And the block house is particularly in demand - a cladding board with a convex front side and a flat wrong side. To simplify the installation and ensure the mounting of a greater degree of reliability, this type of lumber on the sides is equipped with special docking elements - spikes and grooves.

On the modern market, several types of block house are presented - vinyl, metal and wooden. The block house made of wood is especially popular; for its production, semicircular parts of logs from oak, aspen, ash, pine, cedar, spruce, Siberian larch are used.

The pros and cons of a block house are to a large extent determined by the properties of the wood itself.

Eco-friendly block house

Like all lumber, the block house is environmentally friendly, as it is made from natural raw materials. Therefore, this type of decoration materials is absolutely safe for health and does not cause allergies. It is widely used for interior decoration, which ensures a comfortable and favorable microclimate in the rooms.

A block house made of coniferous trees (for example, Siberian larch) is especially in demand, since during operation such decoration, due to the high resin content, emits special volatile substances - volatile products. They disinfect the air, destroying pathogenic bacteria and microbes. In addition, resins increase the waterproofing properties of wood, prolonging the life of the finish.

Benefits of a block house:

- Low cost and availability of raw materials,

- Environmentally friendly - wood is harmless and does not emit toxic substances,

- The aesthetic appeal of the facade and interior,

- Ease of installation

- Strength, durability and wear resistance,

- Simplicity in processing and painting,

- Heat and sound insulation

- The material is suitable for cladding stone, brick, wooden, block and other walls.

How to choose a block house for exterior decoration

For exterior decoration, choose a block house made of pine. Pine is an affordable raw material that is distinguished by its strength and resistance to moisture. Such wood does not decay and does not crumble over time. To finish the facade, take wide boards - at least 150 mm.

The surface of the wood should be smooth and even with a minimum number of knots. This will provide a pleasant and aesthetic appearance of the facade. These include a block house of grade A. In addition, this category is easier to install.

Buy a block house from the manufacturer. This guarantees the quality of the product, because experts carefully monitor each stage of production. At the same time, you will save considerable money, because intermediaries charge prices at times.

The Drev-Market company suggests to buy a block house from a pine. We independently produce finishing materials and use condensation drying in the production.

Drying of lumber is an important stage in the manufacture of which the longevity of lumber depends. Condensation technologies, unlike others, remove excess moisture from the surface of each wood species evenly.

This method will preserve the natural properties of the material and extend the service life. In addition, it will significantly reduce the amount of marriage, which improves the quality and appearance of the block house.

How to fix a block house outside

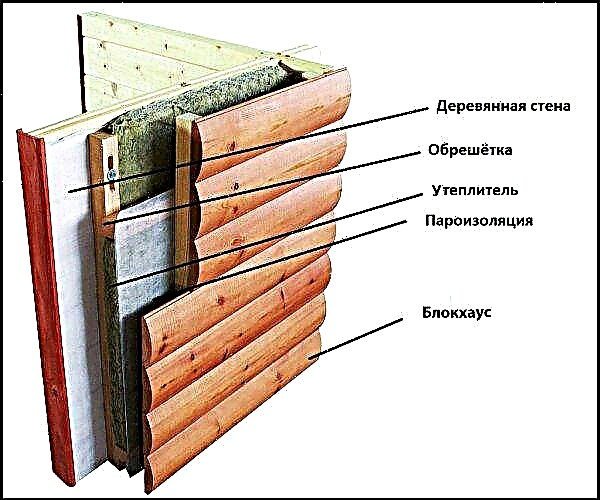

Before installation, it is necessary to prepare the walls and material. After the purchase, the block house is left for 1-2 days in the room, so that the wood "gets used to". Installation begins with laying a vapor barrier, after which they put a crate, insulation, wind protection and a second layer of crate (counter-crate).

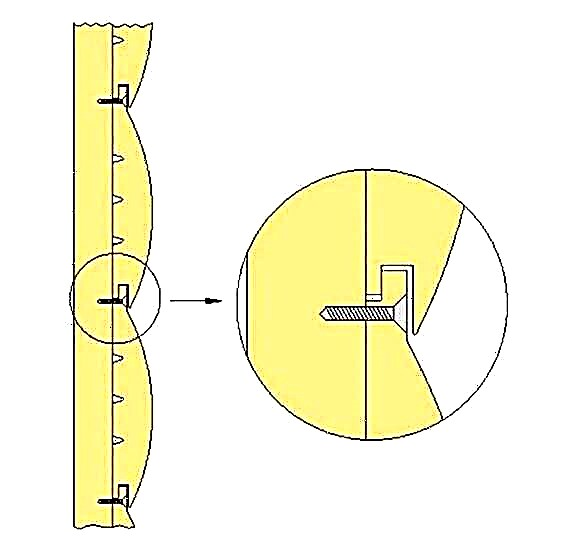

There are several ways to fix a block house. For fixing use self-tapping screws and nails. The most optimal option is considered, in which the screw is screwed into the base of the stud and, when mounting the next board, is completely masked with a groove.

Note that the location of the board is of great importance - the board is placed with the spike up. This eliminates the accumulation of moisture and dust in the groove, which will keep the material longer.

On how to properly install a block house outside the house, see the video.

How to care for a block house

Wood requires special care. With proper processing, it will last 6-7 decades. Therefore, do not ignore this step. Use protective coatings, which include varnishes, paints, flame retardants and antiseptics.

First, a primer is applied to the surface, then a colorless varnish or paint. When the coating dries, grind the surface using a grinder or sandpaper.

After sanding, apply 2-3 coats of varnish or paint of the desired color. At the same time, do not forget to update the coverage once every 6-7 years. It is better to use the same paints and varnishes so as not to remove old layers of paint.

Such protection will eliminate the appearance of mold and rot, insects and scratches. The house will retain an attractive appearance for a long time!

What is a block house?

A tree has never gone out of fashion. Frame houses and various log cabins literally got a second life. Lumber for finishing work is no less in demand in our “age of glass and concrete”. Therefore, in retail outlets you can see a large assortment of cladding products of various cross sections. Especially among them it is worth highlighting the so-called “block house”, which is one of the leaders in terms of sales.

Block house wall

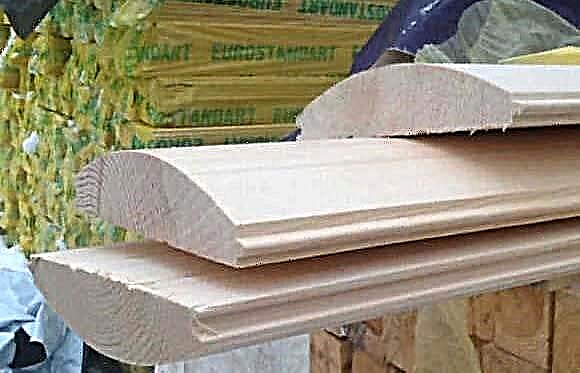

Important! Each panel of the block house on the back side is provided with longitudinal grooves (one large or several small). They are milled here in order to provide ventilation for the finished skin in order to remove moisture and remove thermal stress arising from temperature changes. We can say that the presence of this element is the generally accepted rule of good taste in the production of all modern profiled parts from wood.

Section Features

This material is often called a special type of lining. It has a similar scope, principles of application, is produced by a similar technology and from the same raw materials. But there are differences too. Therefore, let's still consider the block house as a cladding profiled board.

Unlike other profiled solid wood products, the block house is an imitation of logs. After covering the walls, the house will look like it is a log house, and it does not matter what the supporting structures are made of. This effect is achieved, first of all, due to the rounded front layer, as well as the use of solid wood without any signs of adhesive splicing.

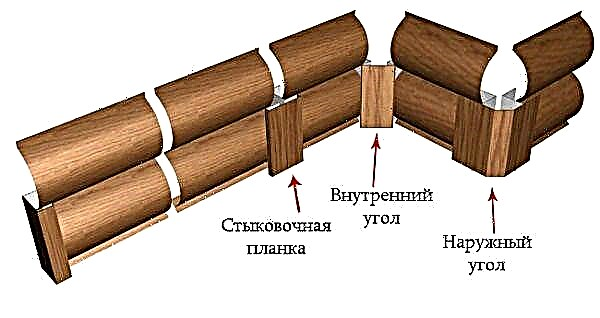

A significant element of the block house panel is a well-developed castle. Each product has a spike and a groove. Thanks to this solution, it is possible to:

- collect the skin without end-to-end gaps between the elements,

- apply the hidden mounting option when the nail / screw or kleimers are closed with the next panel,

- increase the overall installation speed.

Raw materials used and production

You can make a block house from almost any wood. For this, hardwood roundwood can be used: oak, aspen, alder, linden. However, the most popular products made of pine or spruce. Domestic needles are relatively inexpensive, it tolerates moisture differences and is characterized by sufficient durability.

Important! For the manufacture of a block house, an exclusively healthy, lively forest is selected. The use of dead wood or a burner for a block house is unacceptable, due to a decrease in the strength characteristics and durability of such raw materials.

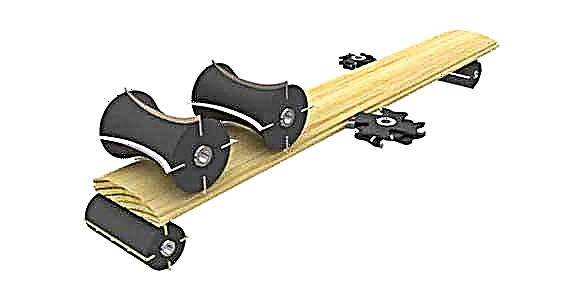

To get a block house, the log is first dissolved on edged lumber. Then, workpieces that are suitable for the cross section (this can be either a bar or a board) are combined into packages and placed in drying chambers. Through controlled heat treatment, the percentage of moisture in the materials is reduced to 10-12%, which allows to obtain a stable billet that can be processed qualitatively on machines.

Then, on high-speed cutting equipment, the milling of the working elements of the part is performed (rounded front, back flat side with grooves, spike / groove). The lamella block of a house is usually formed in one or two passes, and then cuts along the length.

At the final stage, the products are inspected, measured and sorted into categories, depending on the identified defects (wood defects, processing defects ...) and deviations from the given sizes. The most recent operation may be the packaging of profiled parts in a protective plastic film.

Typical profile drawing

Packaging a profiled product that has undergone multi-stage processing is an important circumstance, since allows you to keep the moisture of the product and protects it from dust and dirt. If the seller offers you to purchase a block house without vacuum packaging, then most likely you are buying a low-quality product of natural humidity and, as a result, during operation, it will begin to crack and twist. Be vigilant and do not make decisions based only on cheap price.

Block house prices

| Product name | The price of the product |

|---|---|

| Block house 28 x 140 mm - grade "A" | 515.00 rub |

| Block house 28 x 145 mm - grade "A" | 515.00 rub |

| Block house 36 x 140 mm - grade "A" | 610.00 rub |

| Block house 36 x 190 mm - grade "A" | 610.00 rub |

| Block house 45 x 190 mm - grade "A" | 790.00 rub |

| Block house 45 x 240 mm - grade "A" | 840,00 rub |

Regulatory documents and sorting in the production of a block house

This material is new, which came to us from abroad, and for it in our country there are no GOSTs that would normally describe all the nuances of products and could qualitatively regulate relations between the buyer and the manufacturer.

Therefore, manufacturers use those standards that are similar in spirit or more suited to the specific conditions of their production. Therefore, in the domestic market there are so many options for a block house.

Most often, for reference, they indicate the Soviet GOST 8242-88 Profile details of wood and wood materials for construction. From its provisions are taken data:

- about permissible geometry deviations when cutting parts,

- about the parameters of the purity of processing (roughness),

- about acceptable defects (on visible / hidden surfaces of the lamellas, under a transparent / opaque coating),

- about the humidity of the product (up to 12% of the finished material can be mounted inside the room, up to 15% - outside the house),

- about packaging and transportation rules,

- about quality control methods.

Important! Knots on the front surfaces are allowed in unlimited quantities, both dark and light. But only - captive and no larger than 1/3 of the width of the lamella, as they do not spoil the appearance and do not reduce the strength of the material. Non-through cracks up to 1/6 of the length of the block house and a depth of up to 1-3 mm are also allowed. Rot is prohibited in any form.

Some manufacturers are guided by foreign standards. For example, many refer to Solid softwood paneling and cladding - Machined profiles with tongue and groove, German version EN 14519: 2005 - a German version of the European standard with the title: “Panels and cladding from coniferous massif - with a profiled groove and crest”. In many respects, it is similar to our GOST, but among other things, it is proposed to distinguish two quality classes: A and B.

Blockhouse grade A

Blockhouse grade AB

Blockhouse grade C

Currently, the most common types of block house on the lumber market in Moscow and the Moscow Region are grade A, AB and grade C. The consumer has the opportunity to buy a block house suitable to his category in accordance with the requirements for a sheathed room or a mounted structure. Categories can be called as you like, "extra / classic", "grade A or B" or some intermediate options "AB" or third grade (category C) here, as a rule, there is no exact finishing specification of the material. Products of better quality are somewhat more expensive, they are used on the facade or for cladding inside the house.

We give an approximate classification and recommended methods of finishing work by categories and grades. Category (grade) A - this is sorted material, with knots of different sizes, but always healthy, and not falling out, there should not be black rotten knots! Areas with a fleecy surface and a slight blunt obzol on the back of the lamella are allowed.

Grade A is ideal for painting transparent varnishes. In fairness, it is worth noting that acquiring such material at an affordable price is quite problematic, this is due to the fact that the tree grows contrary to the wishes of the manufacturer and buyer. The 6-meter size offered for sale is the most universal for all types of vehicles and lumber blanks. As a result, on a 6-meter part in 1-2 cases out of ten there will be an ideal ratio of healthy knots, and on 8 products a certain amount of dark, but not dropped out knots and sold under grade a material may come from grade AB. Pure ashka should be sought in lengths of up to 4 meters and under the grade "extra" or "prima", the cost of which will exceed 3-5 times the cost of category A_B.

It is possible to compensate for some grade deviations by applying tinting paints or varnishes, thus it will be possible to buy affordable material of good quality and, after protective paintwork, get an excellent aesthetic and durable facade. We recommend comprehensive protection with Krasul paint.

The variety BC and C is characterized by areas with a dark color, fallen knots, a certain amount of sharp wiping and cracks. This variety is usually used for cladding the "back, draft" walls of the house, the manufacture of arbors, cladding dark and other auxiliary premises and buildings on the site. Additional processing with protective and varnish-and-paint compositions will extend the service life of this kind of material.

Which size to choose

The standard and most universal length of a block house can be considered 6 meters, although there are others for sale - shorter options.

The thickness of the products can vary greatly from different manufacturers, as, however, in the line from one company. You can buy a block house with a thickness of 45 mm from us, as well as 36 and 28 mm. These options allow you to choose the most optimal parts for the price and strength for any conditions. For example, on the facade the best choice would be a 45-mm lamella, which is very strong and reliable, does not require the installation of a large number of load-bearing beams on the frame - a step of 600 mm (convenient for installing insulation boards) will be just right here. And thinner products with a thickness of 28 mm will work well in rooms.

The terrace of the house is sheathed by a block house

Attic ceiling decoration - blockhouse

The width of the profiled boards imitating logs is also uneven. There are narrow parts with a width of 140 mm, and there are wider products that are more like a real log - they are just preferable to take on the wall cladding from the street. In rooms, a block house with a width of 140 or 190 mm looks more organically and favorably.

Important! The spike of the block house is always hidden by the groove of the adjacent lamella, therefore, the overall width of the product and the working width are distinguished - that is, the one that remains visible after installation. Do not lose sight of this when ordering material.

The thickness of the house block is determined from the back to the highest point of the radius at right angles.It is usually interrelated with the width of the part so that the optimum proportion of the cross section can be maintained, both in terms of visualization and in terms of strength characteristics (a wide board with insufficient thickness is prone to transverse warping and cracking). Therefore, steel sections of such a plan: 28X140, 36X140, 36X190 or 45X190, 45X240 mm.

Ruggedness and reliability

Subject to certain rules of wood drying and other stages of production, the block house is characterized by excellent operational characteristics:

Subject to certain rules of wood drying and other stages of production, the block house is characterized by excellent operational characteristics:

- does not warp over time and does not crack (subject to deep drying up to 15% wood moisture), which distinguishes it from a massive log,

- possesses high resistance to negative mechanical influences - blows, scratches,

- in case of violation of the integrity, it can be easily restored by grinding and painting,

- very light, due to which the load on the foundation and walls of the building will be minimal,

- withstands significant temperature changes,

- it is easily and simply mounted even without the participation of specialists.

Aesthetic properties

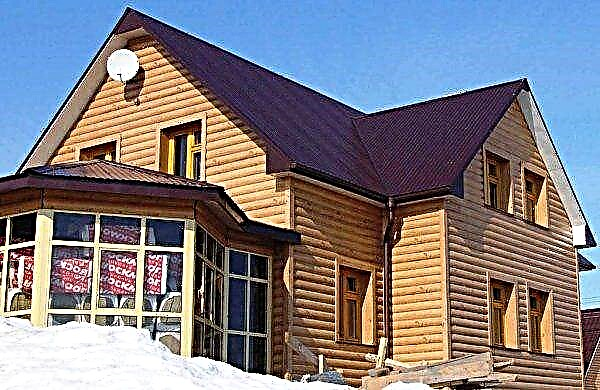

Among the undoubted advantages of a block house is its aesthetics. Using this lumber for cladding the facades of a house made of concrete, foam block, brick or timber, you can give the building the look of a real log house. At the same time, the external decoration, in addition to changing the appearance of the house, will allow:

- protect the walls from external negative factors (moisture, cold, ultraviolet radiation, wind),

- provide additional thermal insulation provided that a heater is used at the stage of installation of the block house.

Please note: the scope of this finishing material is quite wide - it is successfully used not only for decorating facades of houses, but also in the design of arbors, verandas, baths, as well as in the interior. For interior decoration, it is worth choosing narrow panels with a slightly convex front side, due to which the concealment of space in the rooms is minimized.

The walls, decorated with a wooden block house, look not only natural, but also in a special expressive way, and therefore look harmonious with almost any interior design.

Block House Disadvantages

The conditional disadvantages of this type of finishing material include:

- The need for periodic treatment: the surface must be painted and protective coatings applied (antiseptic, stain, mastic, varnish), which allows to extend the life of the finish.

- Low vapor permeability, which can cause condensation to accumulate under the skin.

- Fairly high cost in comparison with other types of finishing materials.

- Low resistance to the negative effects of moisture.

- High flammability.

However, almost all of these shortcomings of the block house can be minimized with the right choice of lumber, and it is recommended to pay special attention to the type of wood.

Geometrical parameters.

The standard length of a block house is 3 and 6 meters (the latter option is less common and costs slightly more).

The standard length of a block house is 3 and 6 meters (the latter option is less common and costs slightly more).

The width of the boards is of two types: general (that is, with a tongue and groove) and working (without it). The difference between them is about 6-7 mm. Narrow panels are often used for interior decoration, as well as for cladding arbors, verandas and terraces, wide - for decorating building facades.

The thickness of the lumber is measured at the highest point of the rounded part and directly depends on the width.

When choosing a block house, you should pay attention to the storage conditions of molded products in a warehouse or at a point of sale, since the operational properties of the products directly depend on them.

In particular, lumber should be stored in unheated enclosed spaces or under awnings, but without fail in factory packaging and on pallets or pallets.

Metal block house

A block house under a log is a kind of external cladding, traditionally representing a wooden panel. The section of the block house is a circle segment, the side edges are provided with a spike and a groove for connection. When assembled, a canvas is obtained that looks like a log house from a log turning.

Natural wood is not the most successful material for outdoor decoration. Despite all the stabilization measures carried out by manufacturers, Natural block house is subject to many harmful processes:

- Warping.

- Susceptibility to moisture.

- Flammability.

- Rotting, the appearance of insects.

- The need for periodic staining.

These shortcomings prompted manufacturers to find a substitute for natural wood. In this capacity, a galvanized steel block house has been developed.

It is completely devoid of the disadvantages of wood panels:

- Resistant to water.

- Not subject to decay.

- Appearance does not change over time.

- No maintenance required.

- Installation is simple and available for independent execution.

At the same time, there are disadvantages:

- Quite a high coefficient of thermal expansion.

- Low soundproof ability.

- Mechanical influences cause permanent dents.

Actually, all the qualities - both advantages and disadvantages - are common to all types of metal siding. If during the operation of the material some precautions are followed, then no problems arise.

Decorative abilities of the material are much wider than that of natural wood. There is a wide range of panels in different color shades. Strength and resistance to all types of exposure make the metal block house the most preferred material that imitates a log.

A complete set of components or, as they are also called, additional elements, allows you to design all facade elements without any tricks - window and door openings, external and internal corners, longitudinal docking of panels and many other functions are successfully performed by extras produced in absolute accordance with the main panels in color, size, etc.

Photos of houses sheathed in imitation block house:

Types of metal block house

The metal block house under a tree has several varieties.  First of all, there are panels with different numbers of waves - single or double wave.

First of all, there are panels with different numbers of waves - single or double wave.

Single-wavelengths have a smaller width, but the wave itself is wider than that of two-wavelength samples.

This allows you to choose a material that will more expressively and correctly look on the facade - the larger the area of the walls, the wider the wave of panels should be, and vice versa.

This ratio allows you to more successfully shape the surface and achieve a greater effect.

In addition, there is a wide selection of panel colors. You can pick up dark or light samples that have the color of a natural tree with all surface elements - knots, cracks, etc. are indicated.

The main material for the metal block house is galvanized steel with a thickness of 0.5 mm. However, there are samples of material from aluminum or copper sheets. They are much more expensive and not so widespread.

Specifications

Metal panels have the following dimensions and characteristics:

- Length - up to 4 m (some panels can be up to 8 m on request).

- Width - 22.6 - 36 mm (without lock), 26-39 cm (with lock).

- The thickness of the material is 0.5-0.8 mm.

- Profile height - 3-4 cm.

- Weight - 2.4-3.6 kg / m2.

- The panels are equipped with anti-lock locks providing enhanced resistance to wind gusts.

- Frost resistance - from -60 ° to + 75 °.

- The durability of the coating is up to 15 years.

- The service life declared by the manufacturer (average) is at least 20 years.

Major manufacturing companies

Among the most famous manufacturers can distinguish the company:

- Grand Line.

- Woodstock.

- Nord House.

- Metal profile, etc.

The number of manufacturers is much larger, but there is no need to list them, since the choice of material should be guided not by the name of the manufacturer, but by the performance and technical characteristics of the casing.

Surface preparation for installation

The surface condition of the walls should be as close as possible to ideal. This is a very important point, since the installation of the casing hides the walls and stops access to them. If there are any flaws, foci of destruction or other problem areas, then all the processes taking place on them will become noticeable only when they reach a critical size.

Therefore, the surface quality must be brought to the proper state, for which it should:

- Remove from the walls all foreign objects and devices - air conditioners, lights, brackets, gutters, platbands, etc.

- Carefully inspect the surface of all walls, make a defective statement.

- Remove the old coat of paint.

- Flaking or flaking areas are removed.

- Discovered flaws are subject to sealing. Cracks should be expanded to find out their depth and configuration. Put holes and dents.

- The best solution would be a solid surface plaster. Especially in the presence of deep potholes, cracks or delaminations.

- To strengthen the wall material and increase adhesion to the adhesive for wall insulation, it is necessary to impregnate with two layers of primer (primer).

Selection and installation of the crate

The crate serves for several purposes:

- Creating a support system for block house panels.

- The formation of a ventilation gap.

- Support for insulation material.

From the point of view of design, the crate is a system of strips located in the transverse direction to the panels, the surface of which forms an even plane. As a material for it, it is customary to use wooden bars, but recently, the use of metal guides for GCR has been considered more practical.

They are free from the typical problems of wooden parts, have a perfectly flat surface, the same thickness and do not change properties over time. Prices for wood and metal parts are almost the same, which is an additional argument in favor of metal strips.

There are two ways to install the crate. The first is two-layer, when at first a system of horizontal strips is installed, between which insulation boards are tightly installed. The strips are carefully aligned on the plane, since then a layer of vertical strips is installed on them, which are the supporting system for the block house panels and, in parallel, provide a ventilation gap. This technology is good in cases where a thick layer of insulation is needed.

The second method is a single-layer crate. A system of brackets (direct suspensions) is installed on the wall surface. The insulation is installed in a dense layer, the brackets are passed through it through the incised sections. On top of the insulation, on the protruding ends of the brackets, vertical battens of the crate are fastened with careful alignment along the plane.

This technology can significantly save on the purchase of slats and speeds up the process of creating a crate. In addition, the tight installation of the insulation reduces the possibility of the formation of cold bridges, dangerous for wall materials due to the possibility of getting wet and breaking.

Installation of insulation, vapor barrier and waterproofing

Insulation is selected according to its technical qualities. The main one is vapor permeability - the ability to pass through a pair of water vapor passing from the inside of the premises through wall materials.

Insulation is selected according to its technical qualities. The main one is vapor permeability - the ability to pass through a pair of water vapor passing from the inside of the premises through wall materials.

If an impermeable insulation is used, the steam is trapped inside the walls, which causes wetting, mold, rotting, corrosion of metal elements and, finally, destruction of the walls.

Impermeable types of insulation, in particular, include polystyrene, EPS, foam, etc. Permeable types of insulation pass steam well, but are capable of getting wet, which significantly impairs their properties.

This type of material includes mineral wool, the best option is basalt (stone) cotton wool. It freely passes steam, has low thermal conductivity.

It should not be considered that impervious types of insulation can not be used. They have excellent qualities, are resistant to moisture and do not lose their qualities over time. In addition, such materials do not need a ventilation gap - it makes no sense. The only condition is the creation of a high-quality internal ventilation system that removes fumes from the premises and eliminates the wetting of the walls.

The insulation is installed on special glue and, at the same time, on fungi - dowels with wide plastic washers on the hat. Some experts try to do only with fungi, without using glue. This option makes the contact of the insulation with the wall less dense, which reduces its efficiency.

The glue is applied to the wall surface with the help of a notched trowel "combed" to obtain an even calibrated layer. The insulation is laid on the surface and attached with fungi (about 5 fungi are needed on one plate of material). Gaps or gaps between the plates are not allowed; if they accidentally appear, fill the gaps with mounting foam.

How to fasten panels

The panels are attached to the crate using self-tapping screws or nails through elongated mounting holes in the lock part. An important point is the need for loose fastening - for free movement of the material when heating or cooling between the nail head or screw and the panel, a gap of 1-2 mm is left.

If this is not done, the panels will begin to bend when heated, which can cause the destruction of the protective coating or corrosion of the material.

For the same reason, the dimensions of all elements must take into account thermal expansion. For example, the length of the panels is made 6 mm shorter so that when heated, the corner or H-profiles do not burst.

Installation instructions

Sheathing the house is as follows (more detailed instructions here):

- Setting the start bar. It should be located strictly horizontally at the bottom point of the facade (or the junction of the facade and basement).

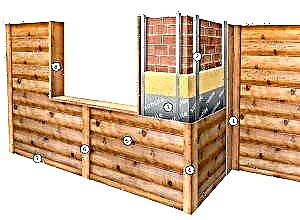

- Installation of corner profiles. The external and internal corners of the facade, window or door openings are made.

- Install H profilescarrying out longitudinal joining of panels.

- The first panel snaps into the pad lock, is installed in the grooves of an angular or H-profile and fixed with screws to the crate.

- Subsequent panels are installed in the same way.

- The canvas is completed by the installation of a finishing strip, which is a decorative element and protects the canvas from rainwater entering the skin.

The metal (iron) block house gives the house the appearance of a wooden log house, but does not have the disadvantages typical of wood. Strength, resistance to external influences, durability of the material make it a serious competitor for other types of casing. The ability to do it yourself helps to save money and nerves, the ease of installation does not require any preliminary preparation. The metal block house is a high-quality durable material with high decorative and performance properties.

House sheathed in block house - Photo

When building a house, building materials of various origins are used. In many countries, in places where people live, they prefer to use natural products. From ancient times they were used for construction and decoration of buildings, bringing positive energy, creating a comfortable living environment.

Features of the wooden block house

Among modern natural materials used for the exterior decoration of buildings, one can increasingly find a block house - a type of wooden lining.

A beautiful and stylish house, sheathed in a block house, is indistinguishable from a high-quality natural log in the photo. In addition to the external similarities, such decoration of buildings has a large number of common positive aspects.

Houses built from natural logs are famous for their longevity. Nowadays, one can often find buildings of more than a hundred years of construction, which have not lost their qualities and are actively used. In such houses it is easy to breathe, there is no increased humidity, a favorable psychological climate is formed.

To replace the popular material, the industry launched the production of inexpensive coatings. These include a metal profiled sheet and siding (see Types of siding for covering a house) that imitate a natural block house. Each of these varieties has a beautiful appearance, good strength indicators, a fairly long period of use, but are not suitable for internal use.

Vinyl or acrylic siding is becoming especially popular for creating stylish cladding for a building. When deciding which sample is best, siding or block house, it should be remembered that natural materials are more suitable for arranging people's places of residence because of their environmental cleanliness and harmlessness.

At the same time, when deciding what is better to sheathe their home, many make a choice in the direction of siding, being guided by affordable prices and a long term of use, the absence of the need for complex care and additional measures to maintain an appropriate appearance. However, this applies only to quality samples from reliable manufacturers.

Positive characteristics

- The house, sheathed in a block house made of wood, combines many advantages that distinguish it from other materials:

- High environmental performance.

- The absence of harmful emissions allows it to be used for decoration not only outside but also inside buildings, in the construction of mansions, summer houses, summer buildings, saunas, baths, utility rooms.

- Good hygroscopicity and vapor permeability of wood contributes to the absorption of excess moisture available in the room and their removal to the outside, leading to a decrease in humidity.

- Due to its good sound absorption and low thermal conductivity, the block house is an additional insulating and sound insulating layer.

- The ease of installation (see Installation of a block house with your own hands), which does not require special equipment and tools, makes covering the house with a block house a fairly simple operation, allowing the careful owner to make a beautiful finish for his own residential and domestic buildings.

- A beautiful appearance allows you to implement modern design projects at a high level of quality, for example, in the popular rustic style, to build beautiful, reliable, durable houses.

Variety of material

The appearance of the block house can be compared with a wooden lining, which has a convex front part, carefully trimmed under a rounded log. There is a variety with a cut convex part. Such a block house has a surface resembling a beam.

Strength, reliability and durability of the surface is ensured by a groove-tongue (tongue, tongue and groove) connection. To do this, on each product, a groove is cut on one side, and a tongue is made on the other. This type of joining of the stripes of the block house with each other creates a high-quality connection and protection against the penetration of moisture and cold.

For the manufacture of a block house used in outdoor decoration, conifers are most often used: pine, larch. Due to the resins contained in them, which is a natural antiseptic, and production technology, the resulting material is durable, resistant to destruction, mold and fungi, and acquires water-repellent properties.

The spruce block house has insufficient strength properties for outdoor use, but it can be successfully used for interior decoration.

From deciduous species of alder, oak, birch, a durable, beautiful and environmentally friendly material is obtained. The dimensions of its use are limited by a rather high price. These types of block houses can be used for stylish interior decoration of cottages, baths, saunas.

The rooms decorated with a wooden block house are very beautiful, have a pleasant golden color, a warm surface. In such a room, an environment comfortable for humans is created that does not harm health, but, on the contrary, has healing properties due to the natural components that make up the composition. The tree is able to relieve fatigue, replenish strength, restore peace of mind.

A house decorated with a block house not only looks beautiful and stylish. Using this finish, you can get a durable wall covering that reliably protects from weathering, creating a comfortable and warm living space.

How to sheathe a house with a block house outside

The block house is a cheap analog of a rounded log, which is in no way inferior in quality and appearance to the original. The block house perfectly imitates the shape of the log, which gives the house a luxurious appearance, and the interior - sophistication.

The material is a board, one side of which follows the round shape of the log, and the other is flat. The imitation of the log looks so realistic that the wall from the block house is difficult to distinguish from the log.

At the same time, the block house is an environmentally friendly and safe material that stores heat indoors for a long time, protects against noise and moisture. The block house is easy to install, process and paint.

1 Block house - beautiful, but is it practical?

A block house is a planed board made of solid wood. The outer side of the board has a rounded shape of a rounded log. Finishing the facade of the house with a block house creates an imitation of a log house. The material can be used for interior and exterior home decoration. Consider a block house for exterior decoration. In addition to excellent aesthetic qualities, this material has a number of other important properties:

- strong, reliable and durable,

- serves as a good insulation for the home,

- does not require special care, easy to clean, damage is easily cleaned by grinding,

- not complicated installation.

As you can see, the cladding of the facade in particular and the house as a whole with a block house outside will help to make it not only beautiful, but also comfortable and cozy. In addition, this material is absolutely safe and environmentally friendly.

Against the background of all the advantages, he has one drawback. Periodically, the block house needs to be covered with special compounds so that it lasts as long as possible. Today this is not a problem, the modern market represents a lot of various means that can provide high-quality protection for a block house for a long time.

2 Choose a block house for exterior decoration - features of choice

There are several types of block house on the market. It is distinguished by color, material from which it is made, size, quality and price. When making your choice, you need to understand its varieties. The ideal material for making a block house is oak. It is very expensive, very prestigious and very reliable. However, not everyone can afford it. Do not be discouraged by the oak, there are options for much cheaper, but quite acceptable quality. The main thing - the block house should be made of wood that is resistant to rot. For example, maple, pine or spruce are great options.

Finishing the gables with a block house and exterior decoration as a whole is much faster and better when choosing a wide-format board, about 150 mm wide. And for the inside, on the contrary, narrow. The different length of the block house, with proper calculation, allows you to purchase the material of the optimal length. Thus, the task is facilitated during its installation - no need to cut. The thickness of the beam also depends on the method of application. If the exterior cladding of the facade is selected with a block house, then the width should be at least 40 cm, and 20 cm is enough for interior decoration.

The wooden block house has several levels of quality - from the premium level to the budget class C. The main difference between them is the frequency and depth of the knots, cracks, gaps and wormholes. Accordingly, the highest, premium class will be, as they say, without a hitch. And, on the contrary, there are a lot of flaws in the C-class beams.

If your plans are for the exterior decoration of the house with a block house, then you are not the poorest person. And this is wonderful! When choosing a material, do not save. Having spent it once, you will solve the problem with insulation and cladding of your home for a long time. Choose only a quality block house from a good manufacturer. It is also important to know where the wood comes from. The best is considered a block house from America, Finland and from the north. When looking at beams, pay attention to their structure and density. The closer the rings are, the higher the density. Such a block house can be bought without a doubt.

3 Exterior decoration of the house with a block house - preparation for installation

The popularity of this material is growing at tremendous speed. Finishing the exterior walls and covering the pediment with a block house is the most traditional way of applying it. It is not uncommon now that one can meet the block-house decoration of fences, arbors and roof overhangs. It is not only beautiful, but also practical. Contaminated facades are easily washed with a stream of ordinary water.

Facing the exterior walls with a block house is not too complicated. The tongue-and-groove connection system is quite simple to install. But still, if you decide to save money and install the beams yourself, then think it over well. This task will require patience and accuracy from you. Any miscalculations and inaccuracies will lead to errors, and all the work will have to be redone.

Like any other tree, the block house also needs to be adapted to the environment. Unpack the packaging and let the material lie down for a couple of days. After proceeding to the processing of the panels with insecticides and an antiseptic. With their help, you can prevent the appearance of insects and mold. After the panels are thoroughly treated with an antiseptic, they need to be sanded with sandpaper. And again go for an antiseptic. True, in some cases, these processing steps are carried out even in the shops of the manufacturer - such material will cost more.

However, in fact, you will save by spending significantly less time on work and less money on the purchase of additional materials and tools.

Take into account that a high-quality antiseptic is quite capable of replacing all kinds of paintwork. It is enough to apply it twice, and you can forget about the coating for the next five to ten years. And a modern antiseptic can give the desired shade and highlight the texture of wood.

4 Installation of a block house - transforming the house with your own hands!

Sheathing of the pediment or decoration of the house outside, in the process of which a block house is used, also allows insulating the house. After all the preparatory procedures are carried out, you can proceed to the direct installation:

- vapor barrier material is attached to the wall. All joints and tears of the film are carefully glued,

- on top of the crate. It is also desirable to treat it with an antiseptic,

- insulation is mounted,

- the insulation is covered with a wind and moisture protective film,

- for ventilation of the block house, a counter grill is installed,

- installation of a block house is being carried out. Work can be started from above or from below - there is no difference. The main thing is to dowel up. It is better to fix the beams using self-tapping screws.

Do not forget that you work with live material. Leave a small gap of a couple of millimeters between the boards. Due to this, the surface will not warp, and temperature changes and high humidity will pass without a trace. Well, of course, all installation work on a block house should be carried out in normal weather conditions. Do not proceed with installation in the event of rain or high humidity.

Covering the basement with a block house is possible, but not very practical. For this purpose, it is better to prefer stone, tile or porcelain. Make sure that all finishing materials are in harmony with each other. It is important to maintain the overall style and not spoil the whole picture, for example, with white plastic windows.

Do not take any action if you have not thought out all the details. You should not be in a hurry in choosing and installing a block house, and you will surely succeed! Choosing an outdoor siding block house as a finish, you choose quality, practicality and beauty for many years.

Covering the house with a block house, put the facade in order

As they say, they are met by clothes. The impression of the house is formed by its appearance. Therefore, it is necessary to take a very responsible attitude to determining the finishing material and designing the appearance of the facade. The construction industry offers a large number of different materials and finishes, and blocking a house with a block house is one of them.

Why choose a block house, its advantages and disadvantages

Any choice is subjective and is often based on personal assessments and preferences. But it is much better when they are confirmed by objective data. When assessing the skin of a house with a block house, the following advantages can be noted:

- the mechanical strength of such a finish provides the ability to withstand numerous, fairly strong, external influences (sand, small stones, accidental impacts), while maintaining the integrity of the skin,

- the appearance in case of damage is easily restored (by grinding and painting the damaged area),

- the aesthetic perception of a natural wood finish is usually extremely favorable,

- the exterior decoration of the house with a blockhouse, which does not belong to the cheapest materials, should create the necessary idea of the owners,

- light load on the foundation,

- external installation of the cladding from the house block is simple and is carried out in a short time,

- additional insulation when the exterior decoration of a wooden house with a blockhouse is performed,

- providing the opportunity to "breathe" at home.

The list of advantages and benefits of this material can be continued, but it is clear that it allows you to provide effective protection for your home at an acceptable cost level. The photo below shows how the facade looks - the block house is used for exterior decoration.

However, this material has drawbacks. The fact is that to ensure long service life, the block house must be periodically painted, varnished or other protective materials. And this is additional trouble and cost.

Covering the house with a block house

Covering the house with a block house

Features of choosing a block house for facade decoration

Despite the simplicity of the exterior, choosing a block house for exterior decoration is not an ordinary task. There are several types of boards, differing both in appearance and in their characteristics.

First of all, you need to pay attention to the width of the block house. Exterior decoration of the house with a block house is done with wide boards, they must be at least 150 mm. It is desirable to select boards all the same.

Then you need to determine the wood from which the board is made. The siding is external, the block house must be used from coniferous trees (larch, pine, spruce), they have increased resistance to decay.

And you definitely need to find out where this board came from for sale. The fact is that wood from the north has a higher density, which affects its other characteristics. This can be determined even visually - in northern wood there is less distance between annual rings.

Of course, you can use for decoration boards not only from the woods of northern forests, but, according to experts, it is preferred, all other things being equal.

Mounting, fixing the block house

When using a block house for exterior decoration, you need to start with the preparatory work. Initially, it is necessary to withstand the boards in the room, freeing them from packaging. This is necessary for their "acclimatization".

Exterior block house

Exterior block house

It should be noted that the sheathing of the house outside the block house in the final form is a design whose purpose is to provide warmth and comfort in the room. How it looks, in a somewhat simplified form can be seen below in the figure (in section). Installation must begin with the fastening of the vapor barrier, after which a crate, insulation, wind protection, counter-lattice are placed. Installation is carried out in the sequence shown in the figure, in the direction from the wall to the casing. After this work is completed, you can proceed directly to fixing the house block. How some of the described works are made, it is shown in the video how to install a board that imitates timber.

Installation of a block house, mounting options.

Installation of a block house, mounting options.

Applying a block house for exterior decoration, you can fix it in several ways, the main ones are shown in the figure below. For fastening, nails or self-tapping screws are usually used, and it is necessary that they be with a corrosion-resistant coating. In the case of fastening according to option B, shown in the figure, then additional wooden plugs that cover the holes will have to be put in the holes for screws on the front panel.

When attaching the board according to option A, the self-tapping screw is screwed into the base of the stud and later, when mounting the next board, it is completely masked by the groove. There are other mounting options, but those presented are the most common. Installation of the board can be carried out both from above and from below, it does not matter.

Regardless of how the board is fixed, its location during installation is of great importance. It must be placed with the spike up, as shown in the figure. This arrangement of the board will avoid the accumulation of moisture, dust in the groove of the board and will contribute to its safety. An important role in this case is played by the air gap formed between the thermal insulation and the outer skin.

Finishing and maintenance of exterior cladding

It should be borne in mind that sheathing a house with a block house outside is not the end of work. It is necessary to take measures to protect it to ensure long-term operation. And here the decisive role will be played by protective coatings - varnishes, paints, mastics, stains and antiseptics.

The surface is primed initially and then a layer of colorless paint or varnish is applied. After the coatings have dried, the surface must be sanded.

After grinding, you can apply the required number of layers of the final coating of varnish or paint. Use for this you need high-quality materials with long life. In many respects, the properties of this coating will determine the service life of the casing of the block house. Periodically, it is necessary to renew the coating (after five to seven years, or maybe more), and it is desirable to apply the same varnish or paint, otherwise the old coating will have to be removed before applying a new one.

Before installation, the house block spike can be varnished to avoid the appearance of a white strip when drying the board.

The stains that have appeared now allow you to give the wood the desired shade or highlight its texture. This can add additional expressiveness to the skin, but the choice of finish is a matter of personal preferences.

Using a house block to decorate the facade of the house allows you to create a peculiar look to it at a reasonable cost, similar to chopped logs. Such decoration, in addition, will provide additional insulation to the house and protection from atmospheric influences. It should be borne in mind that this design option favorably emphasizes the advantages of the house and its owners.